450-MPa-grade hot-radical spangle-free high-strength galvanized plate for pre-engineered metal buildings and production method of 450-MPa-grade hot-radical spangle-free high-strength galvanized plate

A production method, 450mpa technology, applied in hot dip plating process, coating, metal material coating process, etc., can solve the problems of high processing cost and complex process, and achieve social significance, obvious cost advantage, stable production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

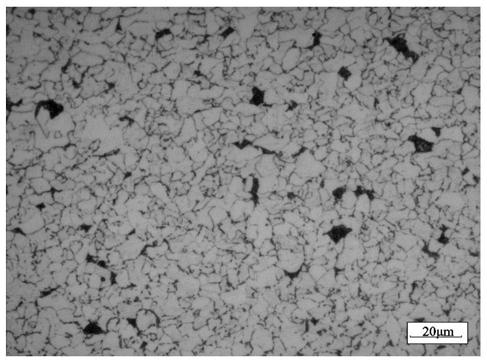

Embodiment 1

[0033] A 450MPa grade light steel construction heat-based patternless high-strength galvanized sheet and a production method thereof, comprising performing continuous casting and rolling on the molten steel to obtain a hot-rolled coil;

[0034] The hot-rolled coil is subjected to a pickling and galvanizing process to obtain a hot-dip galvanized coil;

[0035]The chemical composition and content of the hot-rolled coil: C: 0.045%, Si: 0.2%, Mn: 1.15%, P≤0.012%, S≤0.003%, Als: 0.025%, Ti: 0.013%, Nb: 0.025 %, N≤0.0040%, and the balance is iron and other unavoidable impurities.

[0036] The molten steel is carried out continuous casting and rolling to obtain the production rolling steel temperature control in the hot-rolled coil technology:

[0037] The IH outlet temperature of the hot strip steel production line is 1140-1150°C, the phosphorus removal pressure is 380bar, the finish rolling outlet temperature is 840-860°C, and the coiling temperature is 560-575°C.

[0038] The pr...

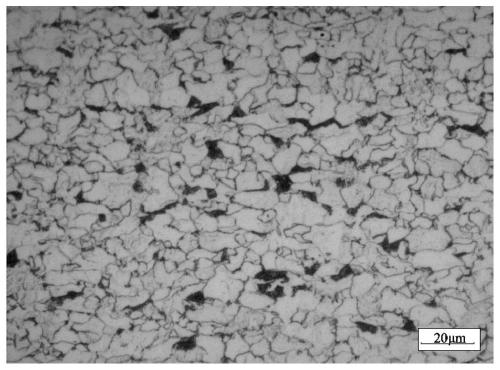

Embodiment 2

[0046] A 450MPa grade light steel construction heat-based patternless high-strength galvanized sheet and a production method thereof, comprising performing continuous casting and rolling on the molten steel to obtain a hot-rolled coil;

[0047] The hot-rolled coil is subjected to a pickling and galvanizing process to obtain a hot-dip galvanized coil;

[0048] The composition range of the hot-rolled steel strip produced by the endless continuous casting and rolling process: C: 0.050%, Si: 0.25%, Mn: 1.10%, P≤0.012%, S≤0.003%, Als: 0.020%, Ti: 0.010 %, Nb: 0.0250%, N≤0.0040%, the balance is iron and other unavoidable impurities.

[0049] The molten steel is carried out continuous casting and rolling to obtain the production rolling steel temperature control in the hot-rolled coil technology:

[0050] The IH outlet temperature of the hot strip steel production line is 1150-1160°C, the phosphorus removal pressure is 380bar, the finish rolling outlet temperature is 820±-840°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com