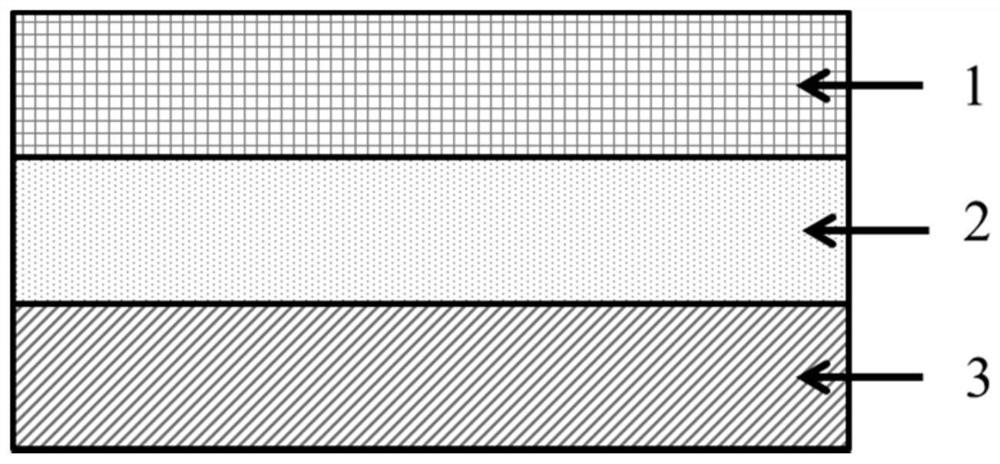

Polyurethane adhesive, PU protective film and preparation method and application of PU protective film

A polyurethane adhesive and protective film technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive additives, etc., can solve the problem of high surface resistance of PU protective film, high requirements for production conditions, poor electrostatic conduction effect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

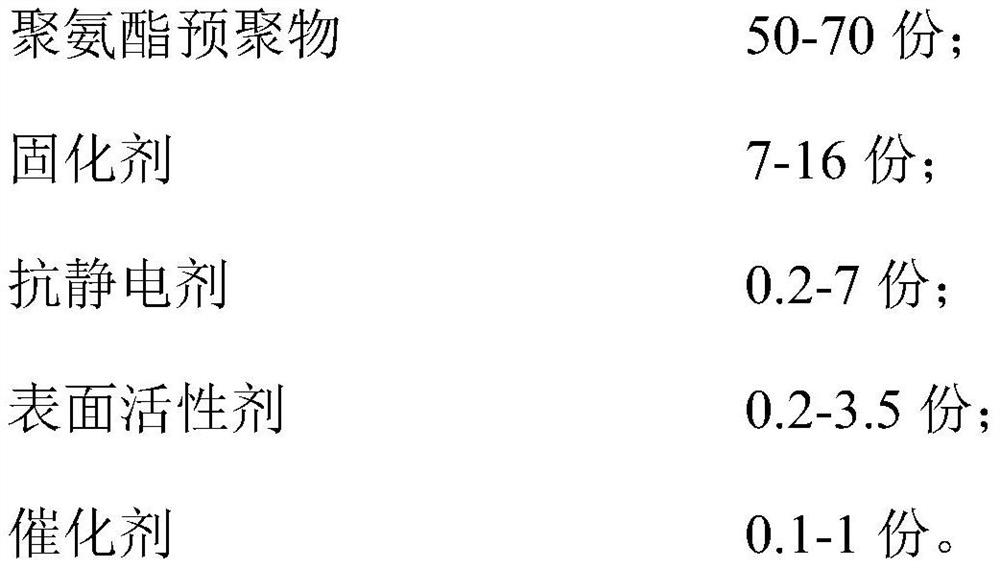

[0102]This implementation provides a polyurethane adhesive, including the following components by weight:

[0103]

[0104]Among them, the antistatic agent is composed of lithium bistrifluoromethanesulfonimide and tetrakis(hydroxymethyl)phosphorus sulfate in a mass ratio of 1:1.

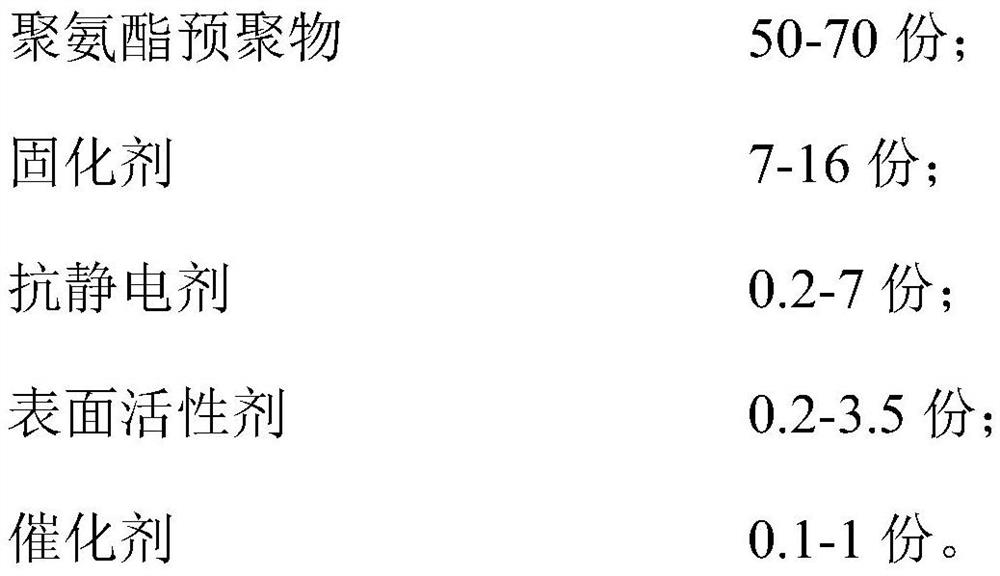

[0105]The above polyurethane prepolymer solution is prepared from the following raw materials:

[0106]

[0107]The preparation method of the above polyurethane prepolymer solution is as follows:

[0108]A: Mix polyether polyol (DP4000E), polyester polyol, hexamethylene diisocyanate, organotin catalyst and toluene, and perform prepolymerization reaction at 75°C to obtain a mixed solution;

[0109]B: Mix the mixed solution obtained in step A, polycarbonate polyol and toluene, and carry out a chain extension reaction at 90° C. to obtain a polyurethane prepolymer solution with a solid content of 60%.

Embodiment 2

[0111]This embodiment provides a polyurethane adhesive, which includes the following components in parts by weight:

[0112]

[0113]

[0114]Among them, the antistatic agent is composed of lithium bistrifluoromethanesulfonimide and tetrakis(hydroxymethyl)phosphorus sulfate in a mass ratio of 1:1.

[0115]The above polyurethane prepolymer solution is prepared from the following raw materials:

[0116]

[0117]The preparation method of the polyurethane prepolymer solution described above is compared with Example 1, except that the content of each raw material is as described above, and a polyurethane prepolymer solution with a solid content of 60% is obtained.

Embodiment 3

[0119]This embodiment provides a polyurethane adhesive, which includes the following components in parts by weight:

[0120]

[0121]Among them, the antistatic agent is composed of lithium bistrifluoromethanesulfonimide and tetrakis(hydroxymethyl)phosphorus sulfate in a mass ratio of 1:1.

[0122]The aforementioned polyurethane prepolymer solution includes the following components in parts by weight:

[0123]

[0124]

[0125]The preparation method of the polyurethane prepolymer solution described above is compared with Example 1, except that the content of each raw material is as described above, and a polyurethane prepolymer solution with a solid content of 50% is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com