Metal color decorative thin slice and decorative metal plate

A metal color and metal plate technology, which is applied in the field of decorative metal plates and metal color decorative sheets, can solve problems such as processing obstacles and deformation, and achieve the effect of small thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

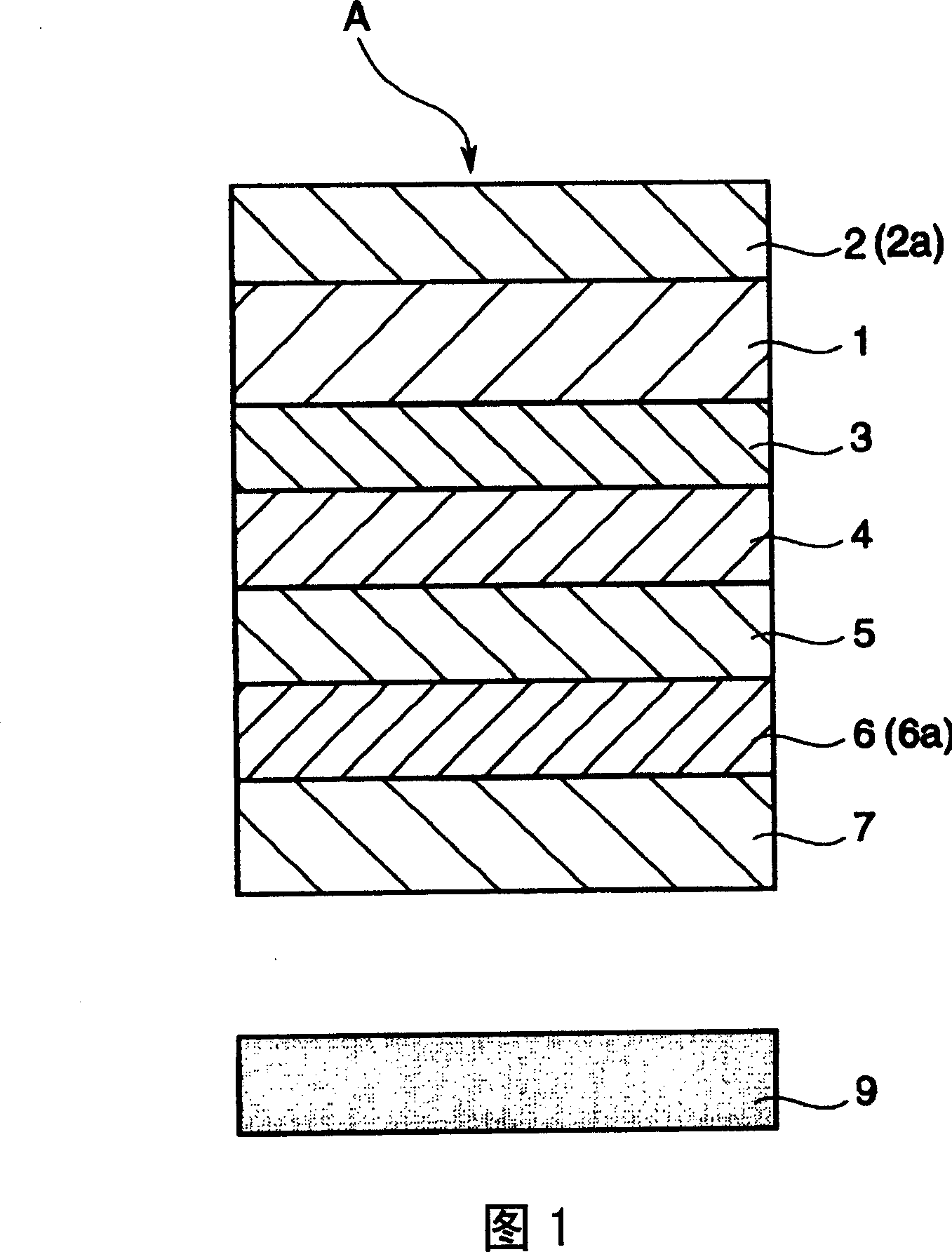

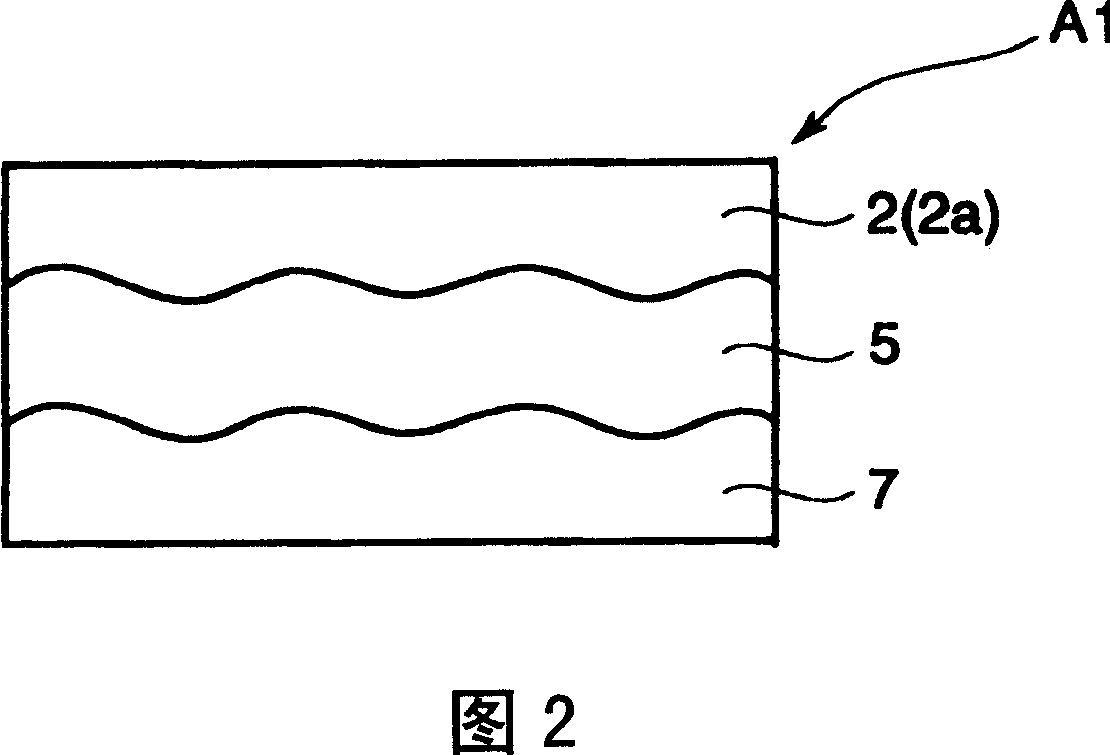

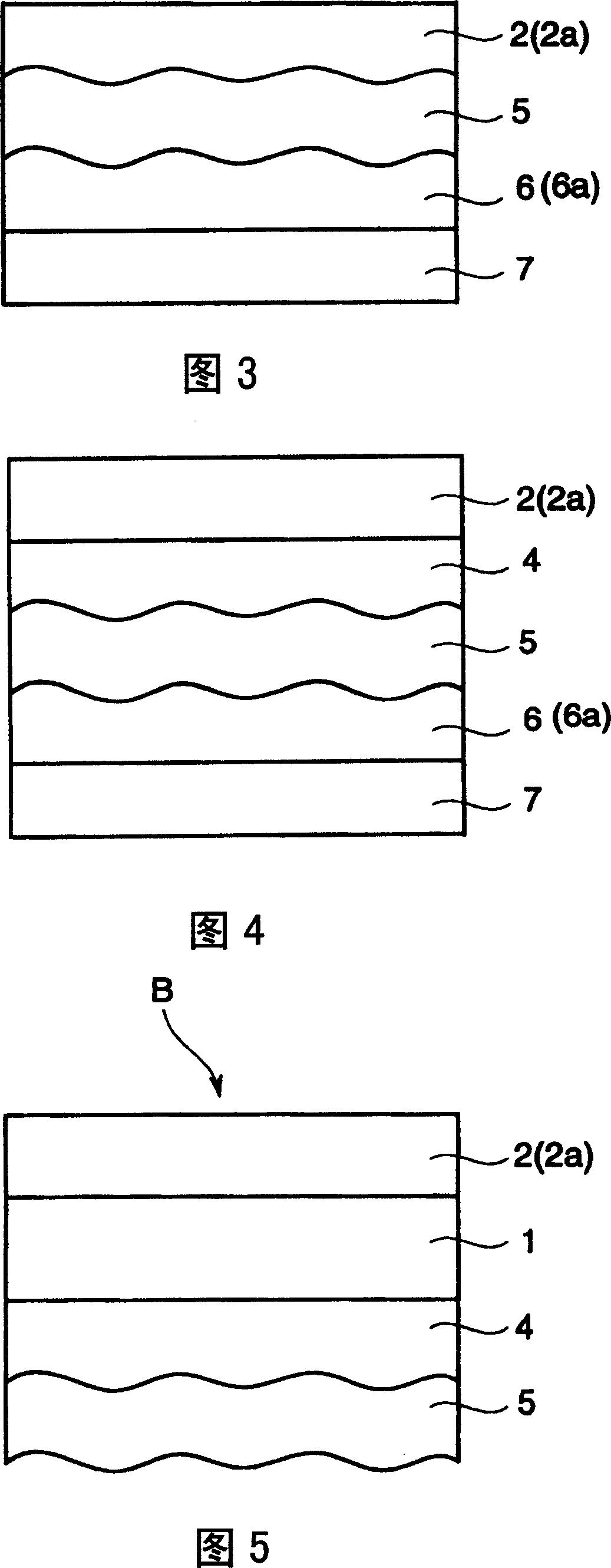

Method used

Image

Examples

Embodiment 1

[0072] Co-extruded polypropylene resin modified with maleic anhydride (modification rate 0.8% by weight, tensile stress at 5% elongation is 80MPa) and polypropylene resin (tensile stress at 5% elongation is 120MPa) and made into thin slices. The thickness of the modified polypropylene is 20 μm, and the thickness of the polypropylene is 20 μm. Corona treatment (6KW, processing speed 20m / min) was performed on the polypropylene resin side of the obtained sheet to adjust the surface tension to 45dyne / cm or more, and then a polyester-based adhesive (Dainichi Seika Co., Ltd.: Seikabond E295 ), dry-laminated with 50 μm-thick aluminum foil that has been subjected to hairline processing. A light black transparent polyurethane resin ink was applied to the aluminum foil by gravure printing, and then, a 25 μm-thick polyester adhesive (Dainichi Seika Co., Ltd.: Seikabond E295) was dry laminated on the printed surface. A polyester film (manufactured by Toyobo) was used to provide a transp...

Embodiment 2

[0082] In Example 1, instead of the hairline-processed aluminum foil having a thickness of 50 μm, a polypropylene film obtained by subjecting a 30-μm-thick hairline-processed polypropylene film to 500 Ȧ of aluminum evaporation film treatment was used, A decorative steel plate was obtained in the same manner as in Example 1.

Embodiment 3

[0084] A polypropylene resin modified with maleic anhydride (modification ratio: 0.8% by weight, tensile stress at 5% elongation: 80 MPa) was extruded to form a sheet. The thickness of the flakes was 30 μm. Corona treatment (6KW, processing speed 20m / min) was carried out on one side of the obtained sheet, the surface tension was adjusted to be more than 45dyne / cm, and then a polyester-based adhesive (Dainichi Seika Co., Ltd.: Seikabond E295) was used, Dry lamination is carried out with 50 μm thick aluminum foil with hairline processing. A light black transparent polyurethane resin ink was applied to the aluminum foil by gravure printing, and then, a 25 μm-thick polyester adhesive (Dainichi Seika Co., Ltd.: Seikabond E295) was dry laminated on the printed surface. A polyester film (manufactured by Toyobo) was used to provide a transparent resin layer.

[0085] Next, an ionizing radiation-curable resin paint (composition shown below) was applied on the transparent resin layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com