Heat dissipation coat

A coat and sleeve technology, applied in protective clothing, special outerwear, clothing, etc., can solve the problems of airtightness, easy to catch cold, etc., and achieve the effect of facilitating life and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

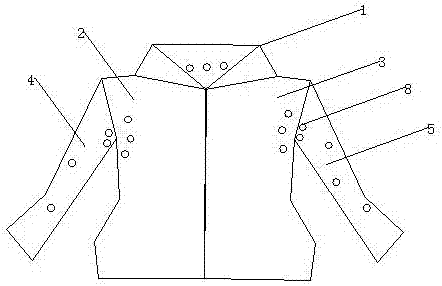

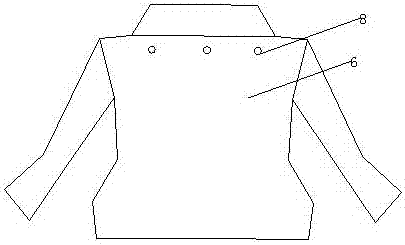

[0030] to combine figure 1 , figure 2 and image 3 In one aspect, this embodiment provides a heat-dissipating top, which includes a collar 1, a right front piece 2, a left front piece 3, a right sleeve 4, a left sleeve 5 and a back piece 6,

[0031] 3-5 through holes 8 are uniformly arranged on the collar 1;

[0032] The right front piece 2 is provided with three through holes 8 near the armpit of the coat;

[0033] The left front piece 3 is provided with three through holes 8 near the armpit of the jacket;

[0034] The left sleeve 5 is provided with 2 through holes 8 near the armpit of the jacket, and 4 through holes 8 are provided in the remaining parts;

[0035] The right sleeve 4 is provided with 2 through holes 8 near the armpit of the jacket, and 2 through holes 8 are provided in the remaining part;

[0036] Three through holes 8 are arranged laterally near the neck of the back panel 6 .

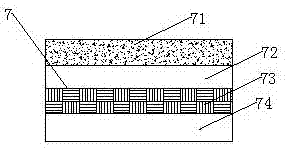

[0037] The upper garment also includes a hanging tag 7, and the hanging tag...

Embodiment 2

[0045] to combine figure 1 , figure 2 and image 3 In one aspect, this embodiment provides a heat-dissipating top, which includes a collar 1, a right front piece 2, a left front piece 3, a right sleeve 4, a left sleeve 5 and a back piece 6,

[0046] 3-5 through holes 8 are uniformly arranged on the collar 1;

[0047] The right front piece 2 is provided with three through holes 8 near the armpit of the jacket;

[0048] The left front piece 3 is provided with three through holes 8 near the armpit of the jacket;

[0049] The left sleeve 5 is provided with 2 through holes 8 near the armpit of the jacket, and 2 through holes 8 are provided in the remaining part;

[0050] The right sleeve 4 is provided with 2 through holes 8 near the armpit of the jacket, and 4 through holes 8 are provided in the rest;

[0051] Two through holes 8 are arranged laterally near the neck of the back panel 6 .

[0052] The upper garment also includes a hanging tag 7, and the hanging tag 7 includes...

Embodiment 3

[0060] to combine figure 1 , figure 2 and image 3 In one aspect, this embodiment provides a heat-dissipating top, which includes a collar 1, a right front piece 2, a left front piece 3, a right sleeve 4, a left sleeve 5 and a back piece 6,

[0061] 3-5 through holes 8 are uniformly arranged on the collar 1;

[0062] The right front piece 2 is provided with three through holes 8 near the armpit of the jacket;

[0063] The left front piece 3 is provided with three through holes 8 near the armpit of the jacket;

[0064] The left sleeve 5 is provided with 2 through holes 8 near the armpit of the jacket, and 3 through holes 8 are provided in the remaining parts;

[0065]The right sleeve 4 is provided with 2 through holes 8 near the armpit of the coat, and 3 through holes 8 are provided in the remaining part;

[0066] Two through holes 8 are arranged laterally near the neck of the back panel 6 .

[0067] The upper garment also includes a hanging tag 7, and the hanging tag 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com