Novel tool bit for numerical-control machining tool special for non-metallic materials

A technology for processing non-metallic materials and machine tools. It is applied in the field of engraving machines. It can solve the problems of lack of texture in lines, lack of layers in engraving lines, and affect the engraving effect of finished products, so as to achieve the effect of uniform force and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

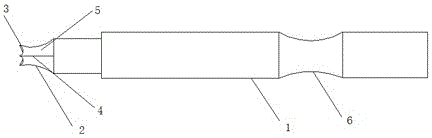

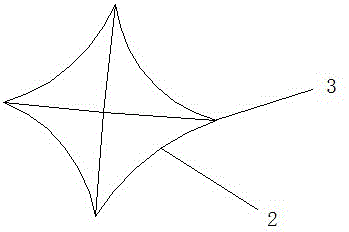

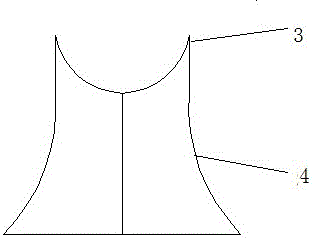

[0030] A new type of cutting head for CNC non-metallic material processing machine tools, including a cutting head 1 and a cutting edge 2, one end of the cutting head 1 is equipped with a cutting edge 2, and the end of the cutting edge 2 is provided with an inwardly concave cross-shaped conical cutting point 3. The side of the blade 2 is provided with a cross-shaped blade 4 , the blade 4 is provided with a radian, and an arc groove 5 is provided between the blade 4 and the blade 4 . The ratio of the length of the knife tip 3 to the length of the curved blade 4 is between 0.4:1 and 0.5:1;

[0031] The ratio of the length of the cutter head 1 to the length of the blade 4 is between 0.2:1 and about 0.7:1;

[0032] The arc length of the blade 4 and the arc length ratio of the arc groove 5 are between 2:5 and 4:5, and the handle of the cutter head 16 is provided with an inwardly concave waist 6, and the waist is polished to a surface finish of at least about 2 microns;

[0033] T...

Embodiment 2

[0035] A new type of cutting head for CNC non-metallic material processing machine tools, including a cutting head 1 and a cutting edge 2, one end of the cutting head 1 is equipped with a cutting edge 2, and the end of the cutting edge 2 is provided with an inwardly concave cross-shaped conical cutting point 3. The side of the blade 2 is provided with a cross-shaped blade 4 , the blade 4 is provided with a radian, and an arc groove 5 is provided between the blade 4 and the blade 4 .

[0036] The ratio of the length of the knife tip 3 to the length of the curved blade 4 is between 0.4:1 and 0.5:1;

[0037] The ratio of the length of the cutter head 1 to the length of the blade 4 is between 0.2:1 and about 0.7:1;

[0038] The radian on the blade 1 is 2.4rad, and the radian of the arc groove 5 is 2.1rad;

[0039] The arc length of the blade 4 and the arc length ratio of the arc groove 5 are between 2:5 and 4:5, and the handle of the cutter head 16 is provided with an inwardly co...

Embodiment 3

[0042] A new type of cutting head for CNC non-metallic material processing machine tools, including a cutting head 1 and a cutting edge 2, one end of the cutting head 1 is equipped with a cutting edge 2, and the end of the cutting edge 2 is provided with an inwardly concave cross-shaped conical cutting point 3. The side of the blade 2 is provided with a cross-shaped blade 4 , the blade 4 is provided with a radian, and an arc groove 5 is provided between the blade 4 and the blade 4 .

[0043] The ratio of the length of the knife tip 3 to the length of the curved blade 4 is between 0.4:1 and 0.5:1;

[0044] The ratio of the length of the cutter head 1 to the length of the blade 4 is between 0.2:1 and about 0.7:1;

[0045] The arc length of the blade 4 and the arc length ratio of the arc groove 5 are between 2:5 and 4:5, and the radian on the blade at the handle portion of the cutter head 16 is 2.4rad, and the arc groove of the arc groove Radian is 2.1rad;

[0046] The length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com