Technical method for imitating copper and gold on surface of magnesium alloy

A process method, magnesium alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of difficult realization of large-scale magnesium products, poor impact resistance, complex equipment, etc., to achieve large-scale industrial production, low cost, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

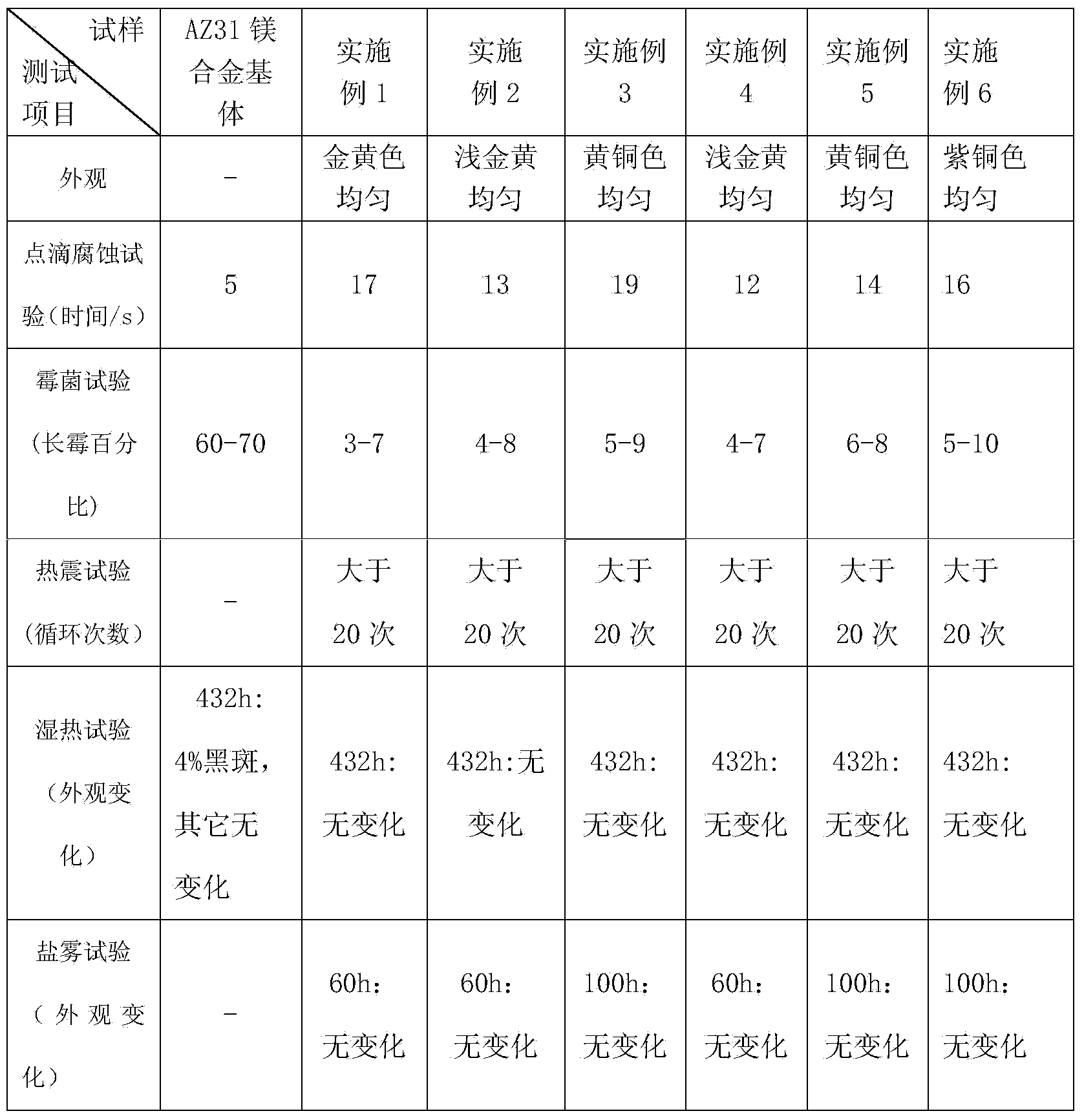

[0044] Polish the AZ31 magnesium alloy plate and wash it with distilled water. Put it into the passivation solution for passivation coloring, the temperature is 100°C, the passivation solution is 0.8g / L sodium triphosphate aqueous solution, pH=8.0. Take it out after 7 hours of heat preservation, put it into water-based acrylic resin for dip-coating and sealing, and immediately take it out and put it in an oven for baking at 150°C for 10 minutes. Various performance tests were carried out on the baked samples, and the test results are shown in Table 1.

Embodiment 2

[0046] Polish the AZ31 magnesium alloy plate and wash it with distilled water. Put it in deionized water for passivation and coloring, the temperature is 100°C, keep it warm for 10 hours, take it out, then put it into water-based acrylic epoxy resin for dip coating and sealing, take it out and put it in an oven for baking, the baking temperature is 160°C , baking time 10min. Various performance tests were carried out on the baked samples, and the test results are shown in Table 1.

Embodiment 3

[0048] Polish the AZ61 magnesium alloy plate and wash it with distilled water. Put it into the passivation solution for passivation coloring, the temperature is 85°C, the passivation solution is 1.5g / L sodium triphosphate aqueous solution, pH=10.0. After 8 hours of heat preservation, take it out, put it in fluororesin for dip coating and sealing, take it out to dry, put it in an oven for baking, the baking temperature is 220°C, and the baking time is 20 minutes. Various performance tests were carried out on the baked samples, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com