Synthetic-wood solid wood composite door and window and manufacturing method thereof

A solid wood composite and production method technology, which is applied to special equipment for doors/windows, door leaves, windows/doors, etc., can solve the problems of high cost, poor thermal insulation performance, complex production process of aluminum-wood, aluminum-plastic composite doors and windows, etc. The effect of increasing added value and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

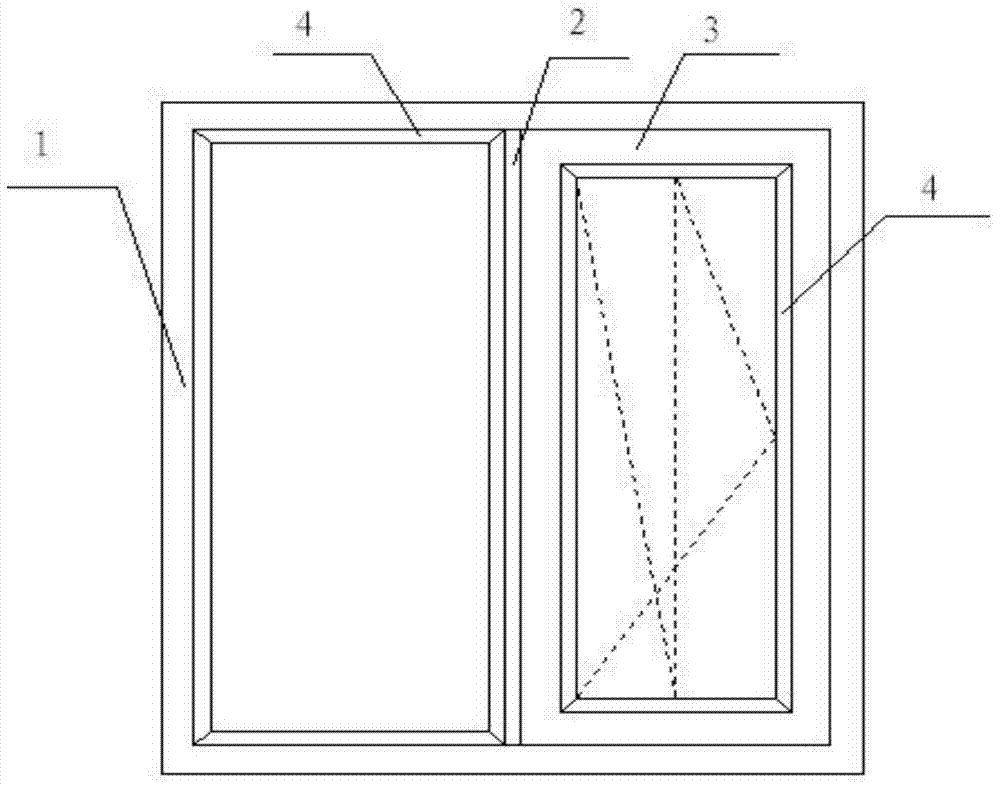

[0019] Specific implementation mode 1: In this embodiment, wood-plastic solid wood composite doors and windows are composed of wood-plastic solid wood composite profiles, glass, accessories, sealing strips and layering strips 4.

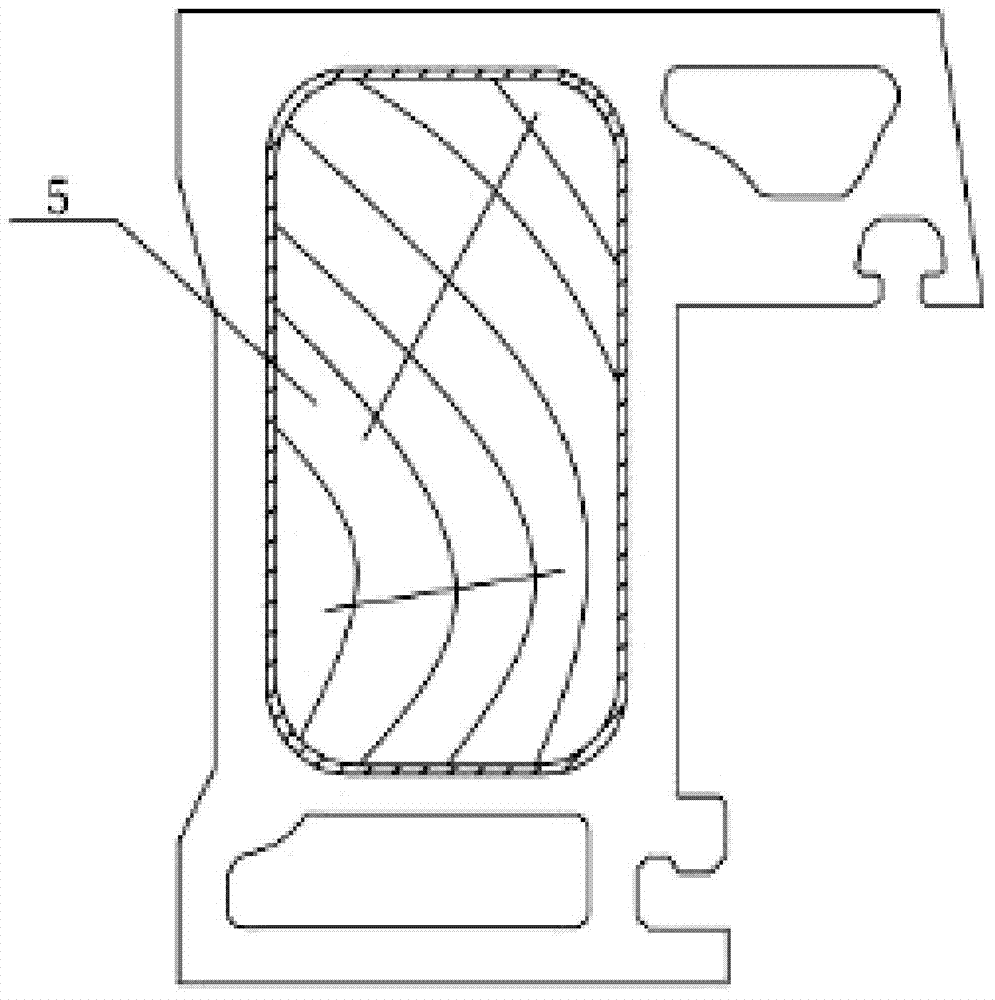

[0020] Wherein the wood-plastic solid wood composite profile is made of a wood-plastic composite material coated solid wood core 5 through a co-extrusion molding process. The wood-plastic solid wood composite profile includes a frame profile 1, a center profile 2 and a fan profile 3. The bead 4 is made of wood-plastic composite material through an extrusion molding process, and the accessories include one or more combinations of hinges, tracks, handles, door locks and braces.

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solid wood core 5 is sawn solid wood, finger-jointed wood, laminated wood, laminated veneer lumber, recombined wood, recombined bamboo, or modified wood. , glue pressed wood or compressed wood. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 in that the sealing strip is made of modified polyvinyl chloride, EPDM rubber, thermoplastic elastomer or silicone rubber. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com