Translucent stretched film

A translucent, stretchable film technology, applied in applications, household appliances, layered products, etc., can solve the problems of high transparency, difficult to see text or patterns, and unavailable substitutes, etc., to achieve excellent oil resistance, Excellent printability, heat sealability, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

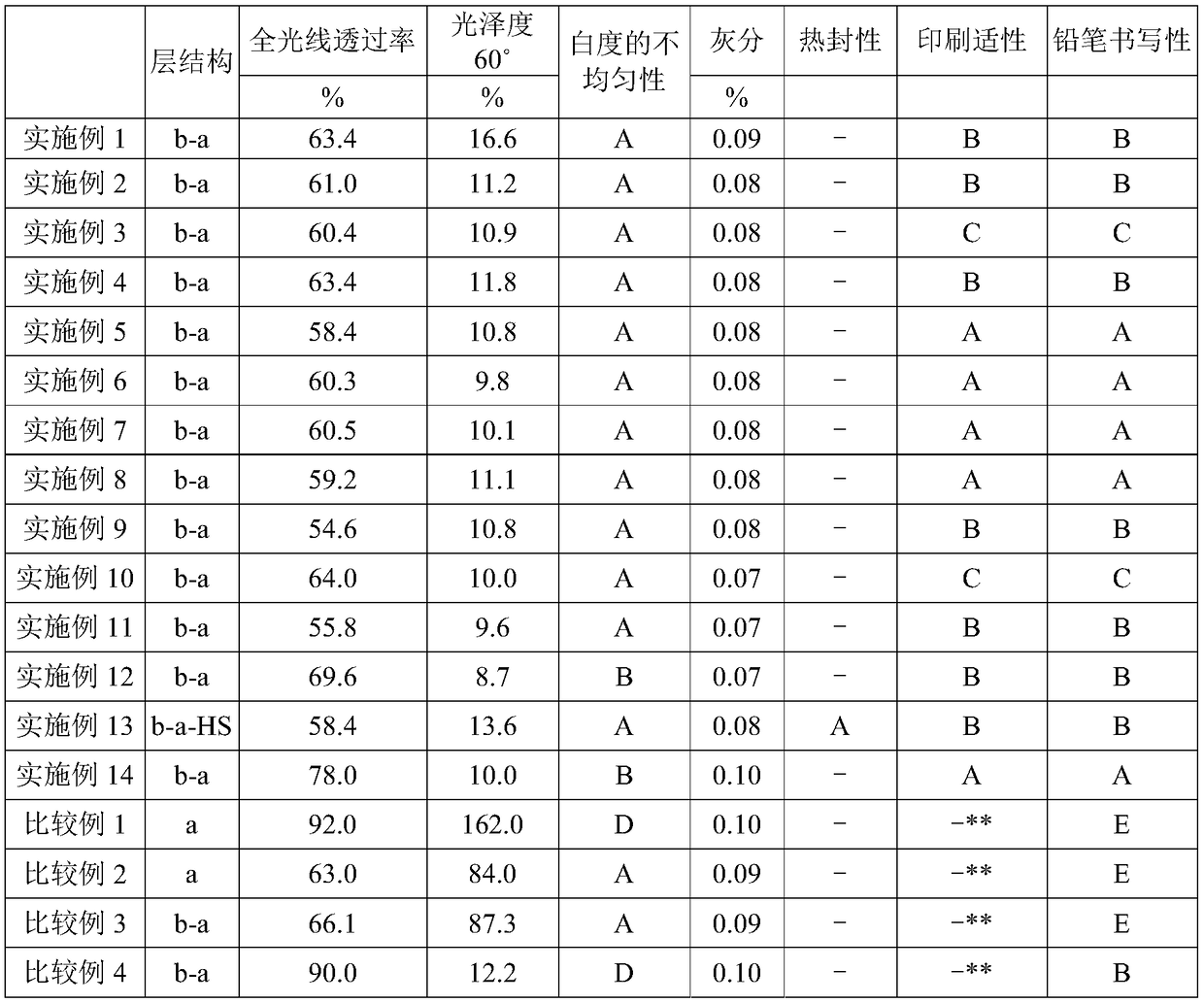

Embodiment 1

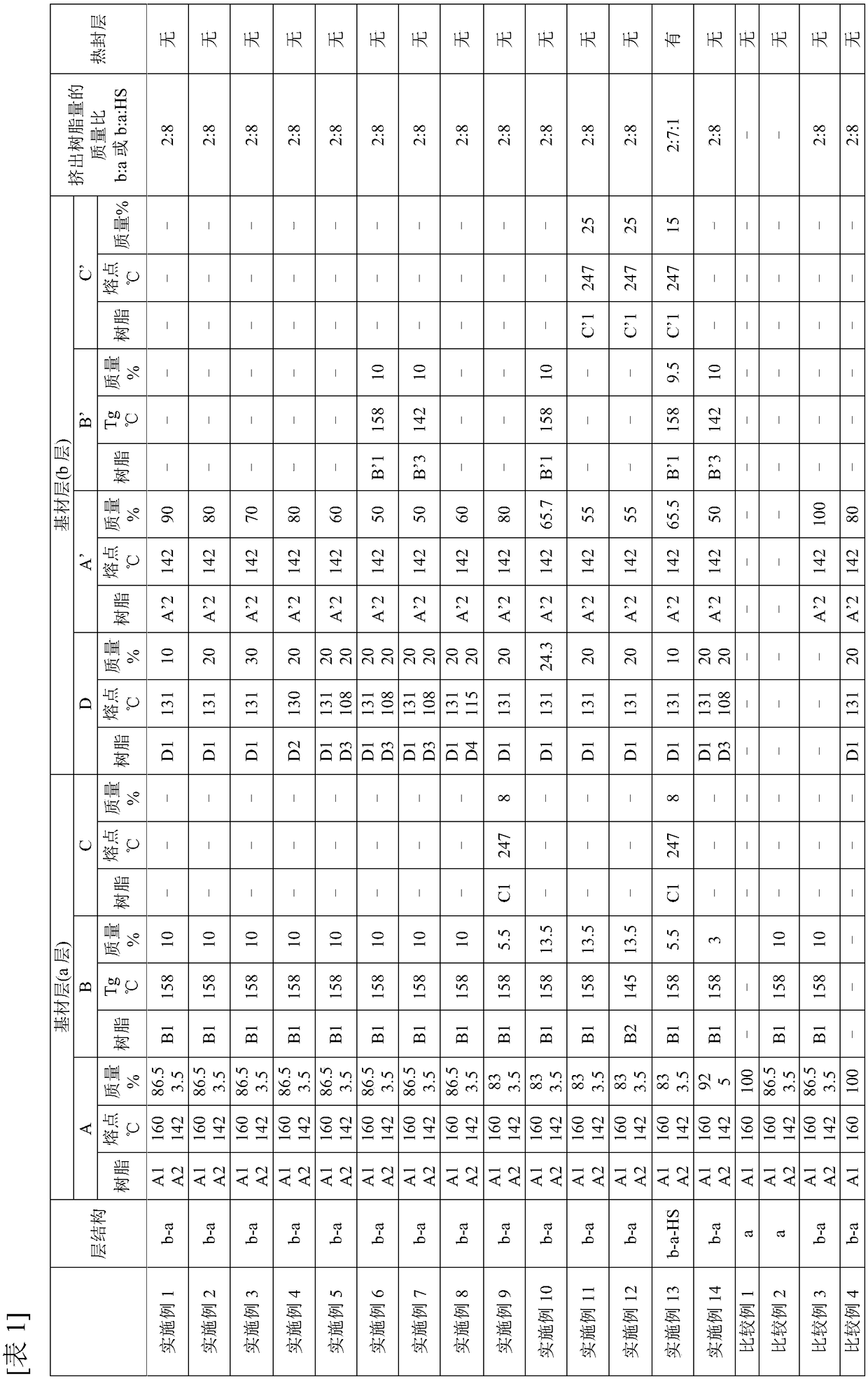

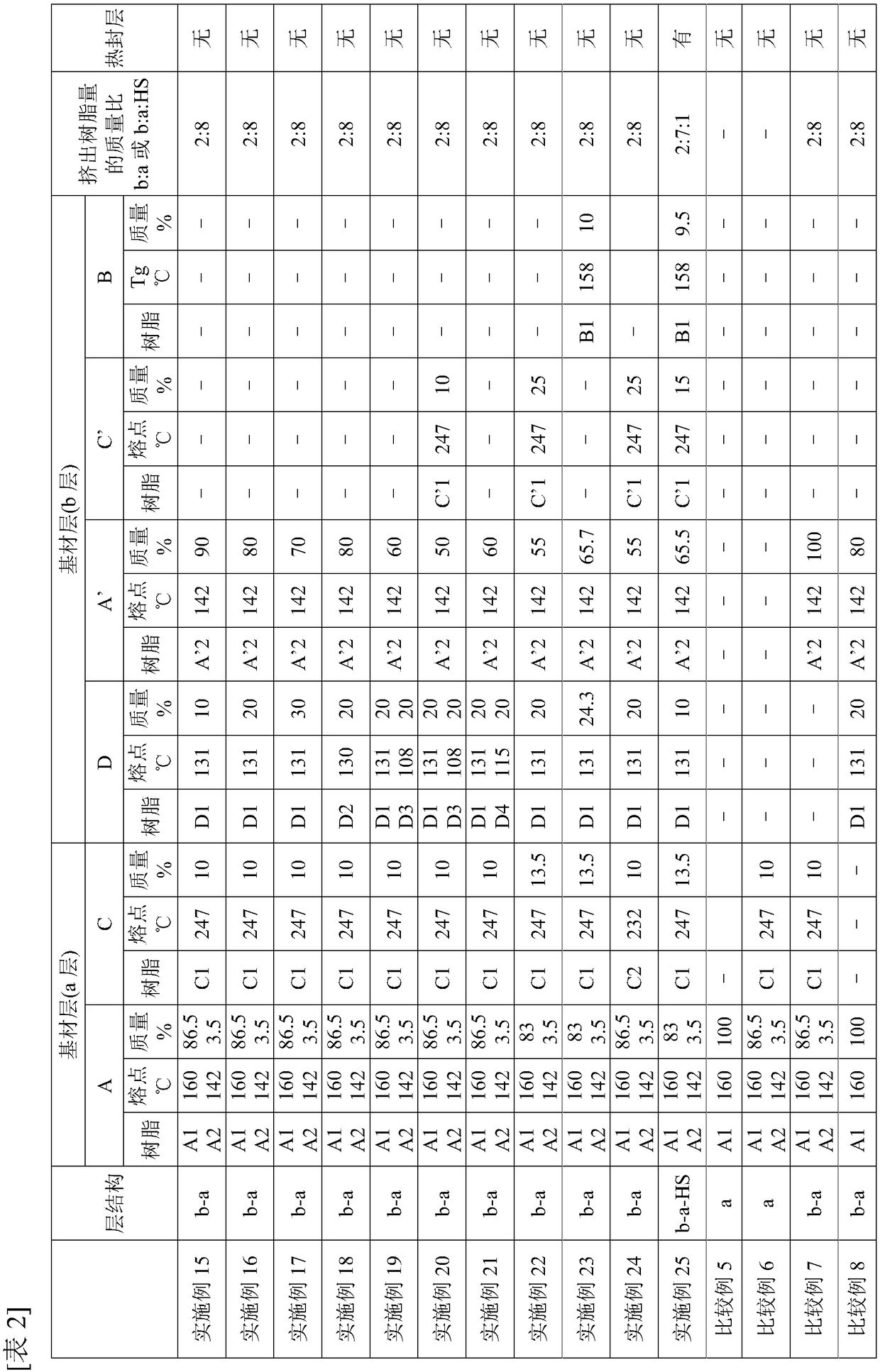

[0289] The pellets of Resin A1, Resin A2, and Resin B1 were dry-blended at the ratios shown in Table 1 using a mixer to prepare a resin composition for a base material layer. Separately, pellets of resin A'2 and resin D1 were dry-blended at the ratios shown in Table 1 using a mixer to prepare a resin composition for a surface layer.

[0290] The dry-blended resin composition for the base layer for forming the base layer was charged from the hopper into the single-screw screw extruder a, and the dry-blended resin composition for the surface layer for forming the surface layer was charged from the hopper into Melt it at 240°C in a single-screw screw extruder b, and laminate these melts into two layers: surface layer (layer b)-substrate layer (layer a) inside a two-layer multi-manifold die The structure is extruded in the form of two laminated resin layers. The mass ratio of the extruded resin amount of the single-screw screw extruder b to the single-screw screw extruder a is b:...

Embodiment 2

[0293] Regarding the surface layer, except that 80% by mass of resin A'2 and 20% by mass of resin D1 were used instead of the ratio of the resin components constituting the surface layer described in Example 1, the same operation as in Example 1 was carried out, and the result was obtained. Stretch film of Example 2.

Embodiment 3

[0295] Regarding the surface layer, except that 70% by mass of resin A'2 and 30% by mass of resin D1 were used instead of the proportions of the resin components constituting the surface layer described in Example 1, the same operations as in Example 1 were carried out, and the results were obtained. Stretched film of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com