Electronic equipment shell, manufacturing method thereof and electronic equipment

A technology for electronic equipment and casings, applied in metal material coating process, fusion spraying, coating and other directions, can solve the problems of inability to make complex 3D structures, poor wear resistance of mobile phone casings, etc., to achieve high market competitiveness, high resistance to The effect of high drop performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

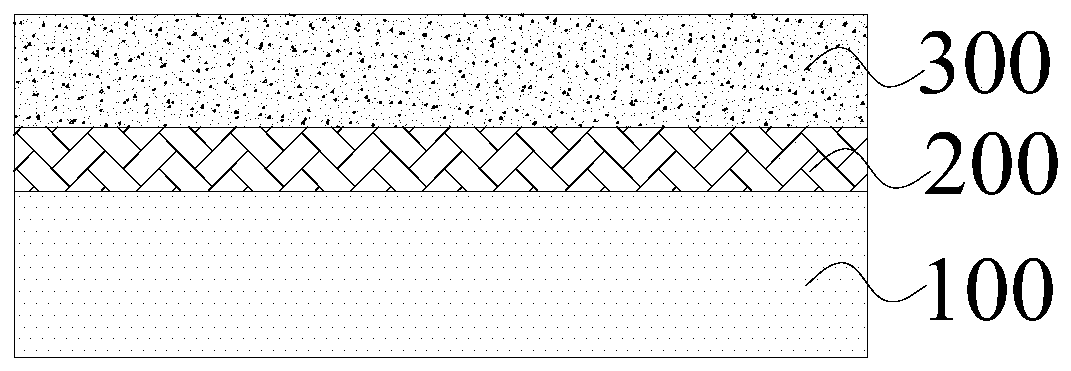

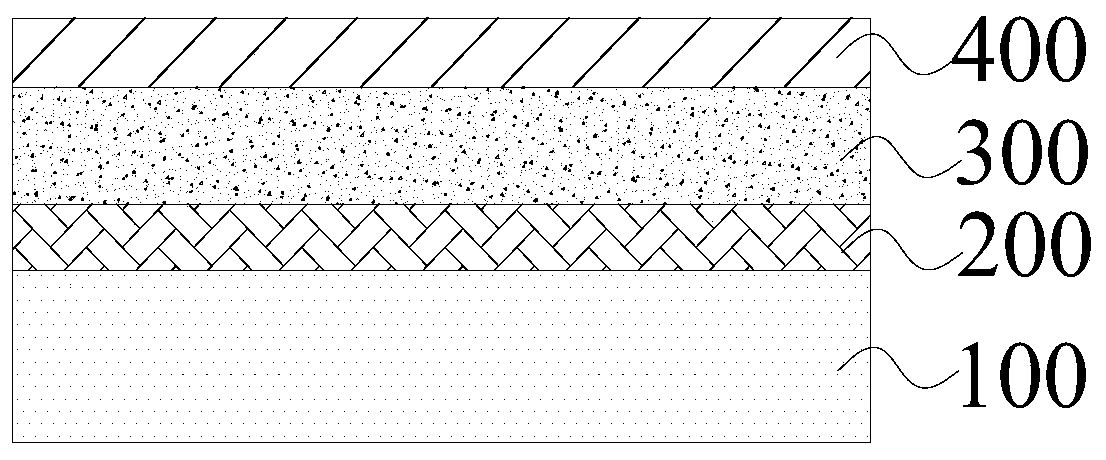

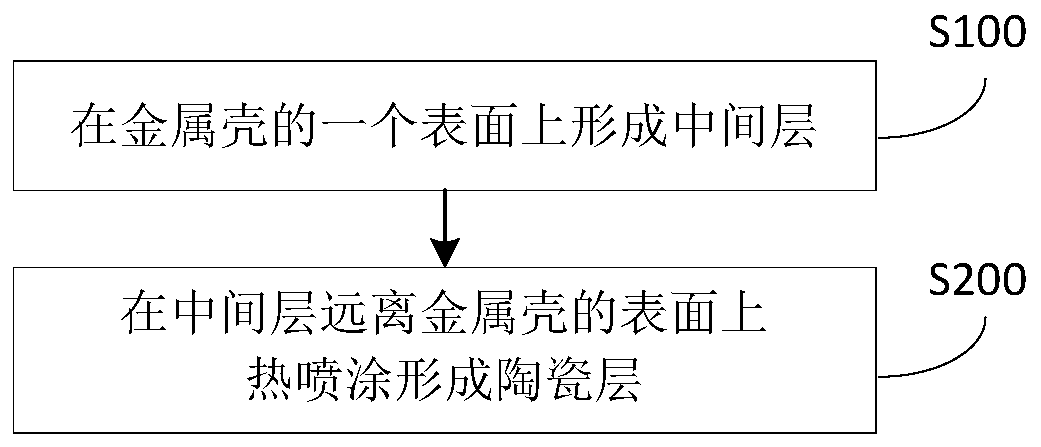

[0062] In this embodiment, the metal alloy is first primed on the surface of the metal layer, and then the ceramic layer is formed by thermal spraying. Among them, Al (type 6061) material is selected for the metal layer, and an intermediate layer of Ni-5w / w% Al is formed by arc spraying on the surface of the aluminum substrate, and then Al is formed on the surface of the aluminum substrate by plasma spraying. 2 o 3 ceramic layer.

[0063] Al of this example 2 o 3 The Ni-5w / w%Al intermediate layer added between the ceramic layer and the aluminum substrate has a binding force test result of 18-23MPa. Compared with Comparative Example 1, the interlayer bonding force can be doubled.

Embodiment 2

[0068] In this embodiment, the metal alloy is first primed on the surface of the metal layer, and then the ceramic layer is formed by thermal spraying. Among them, Al (type 6061) material is selected for the metal layer, and an intermediate layer of Ni-15w / w% Al is formed by arc spraying on the surface of the aluminum substrate, and then Al is formed on the surface of the aluminum substrate by plasma spraying. 2 o 3 -TiO 2 ceramic layer.

[0069] Al of this example 2 o 3 -TiO 2 The Ni-15w / w%Al intermediate layer added between the ceramic layer and the aluminum substrate has a binding force test result of 19-23MPa. Compared with Comparative Example 2, the intermediate layer can increase the interlayer bonding force by about 1 time.

Embodiment 3

[0074]In this embodiment, the metal alloy is first primed on the surface of the metal layer, and then the ceramic layer is formed by thermal spraying. Among them, the metal layer is made of stainless steel (model SUS304), and an intermediate layer of Ni-10w / w% Co is first formed on the surface of the stainless steel substrate, and then WC-10Co-4Cr is formed on the surface of the stainless steel substrate by supersonic flame spraying ceramic layer.

[0075] The interlayer added between the WC-10Co-4Cr ceramic layer and the stainless steel substrate in this embodiment has a bonding force test result of 65-75 MPa. Compared with Comparative Example 3, the intermediate layer can increase the interlayer bonding force by about 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com