Automobile door plate assembling method with multiple inner decorations

An assembly method, door panel technology, applied to doors, vehicle parts, transportation and packaging, etc., to achieve a textured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

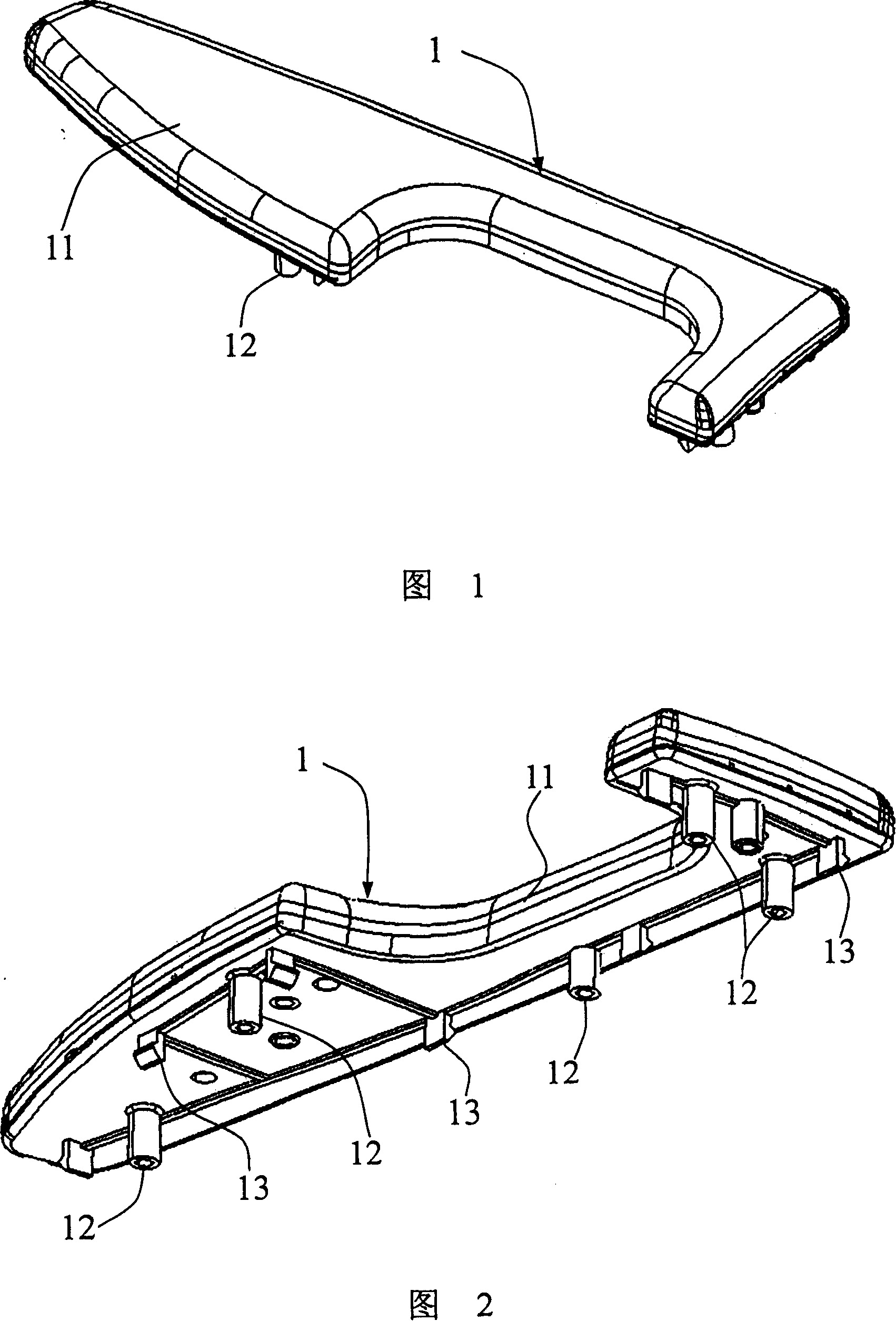

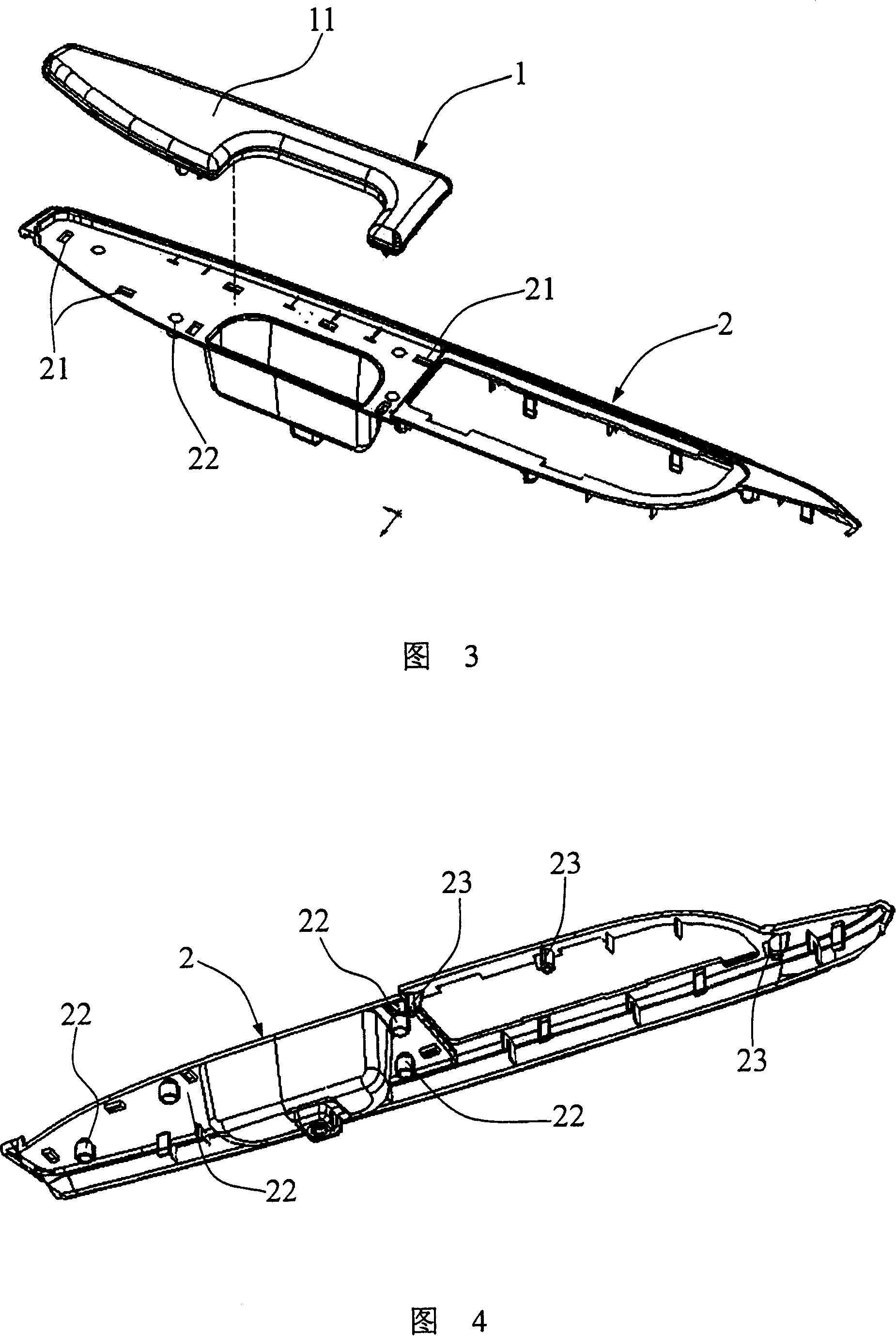

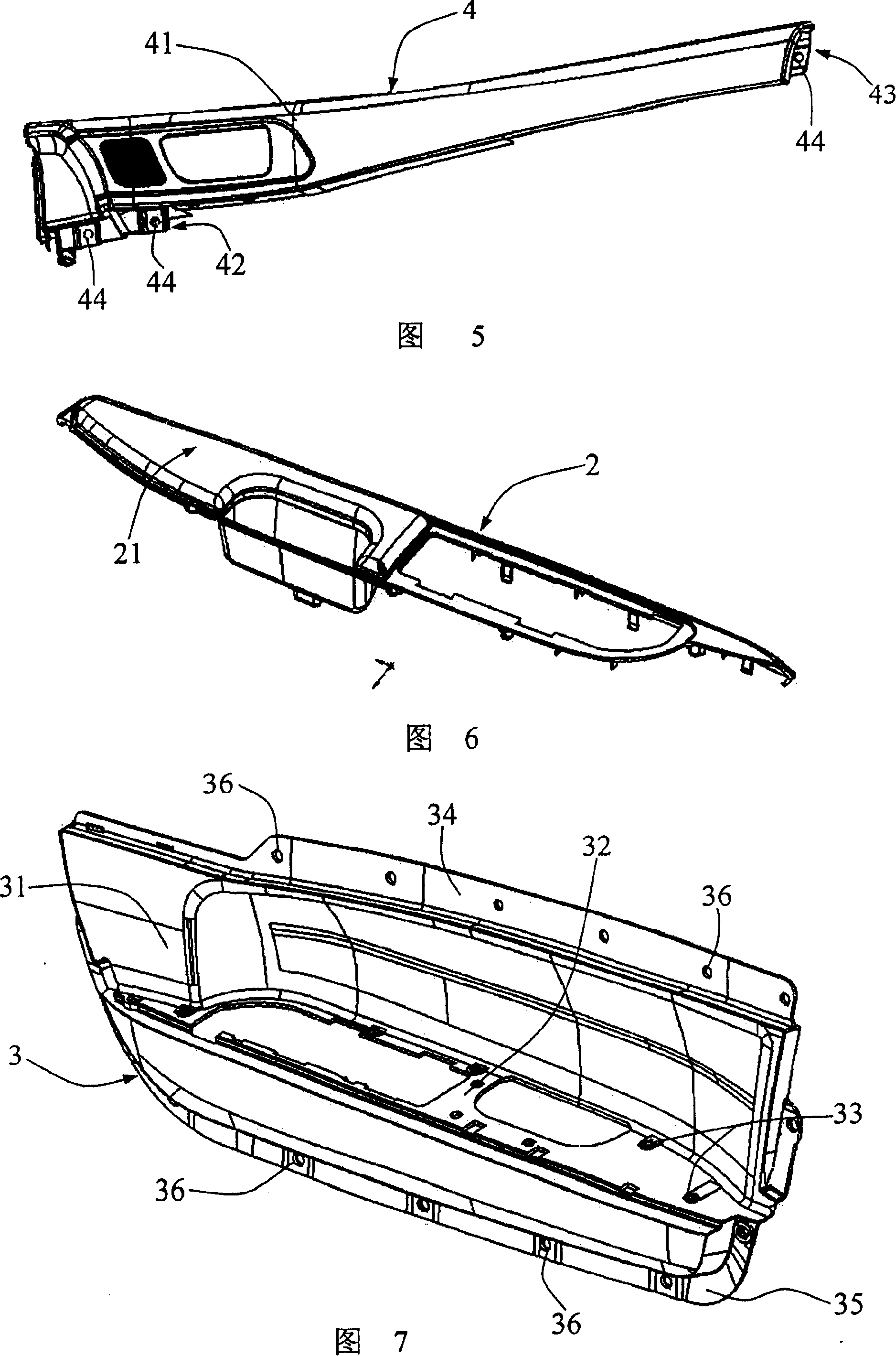

[0028] As shown in FIG. 10 , a method for assembling an automobile door panel provided by the present invention comprises an armrest pad 1 , a wood grain veneer 2 , a middle plate 3 , an upper cover 4 and a lower plate 5 .

[0029] As shown in Figure 1, the armrest pad 1 is to inject the main body first, then place the main body in the foaming mold, and pour it into the foam material. The armrest pad 1 is provided with a joint surface and a bottom surface. After spraying glue on the back of the skin 11 and then heating, the armrest pad 1 is placed on the punch, and the coating skin 11 is placed on the armrest pad 1 to obtain a space for the concave mold corresponding to the three-dimensional shape of the armrest pad 1 . Then the punch is moved up, so that the covering skin 11 is extended and aligned with the bottom contour edge of the armrest pad 1. The bottom of the armrest pad 1 is protruded with several pivot joints 12 and several elastic buckles 13, and the elastic buckle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com