Wood-plastic glazed door and window and preparation method thereof

A glass and wood-plastic technology, applied in the installation of window glass, window/door, window/door frame, etc., can solve the problems of high cost, poor thermal insulation performance, high energy consumption of aluminum alloy doors and windows, etc., and achieve good weather resistance , improve efficiency and reduce rice weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

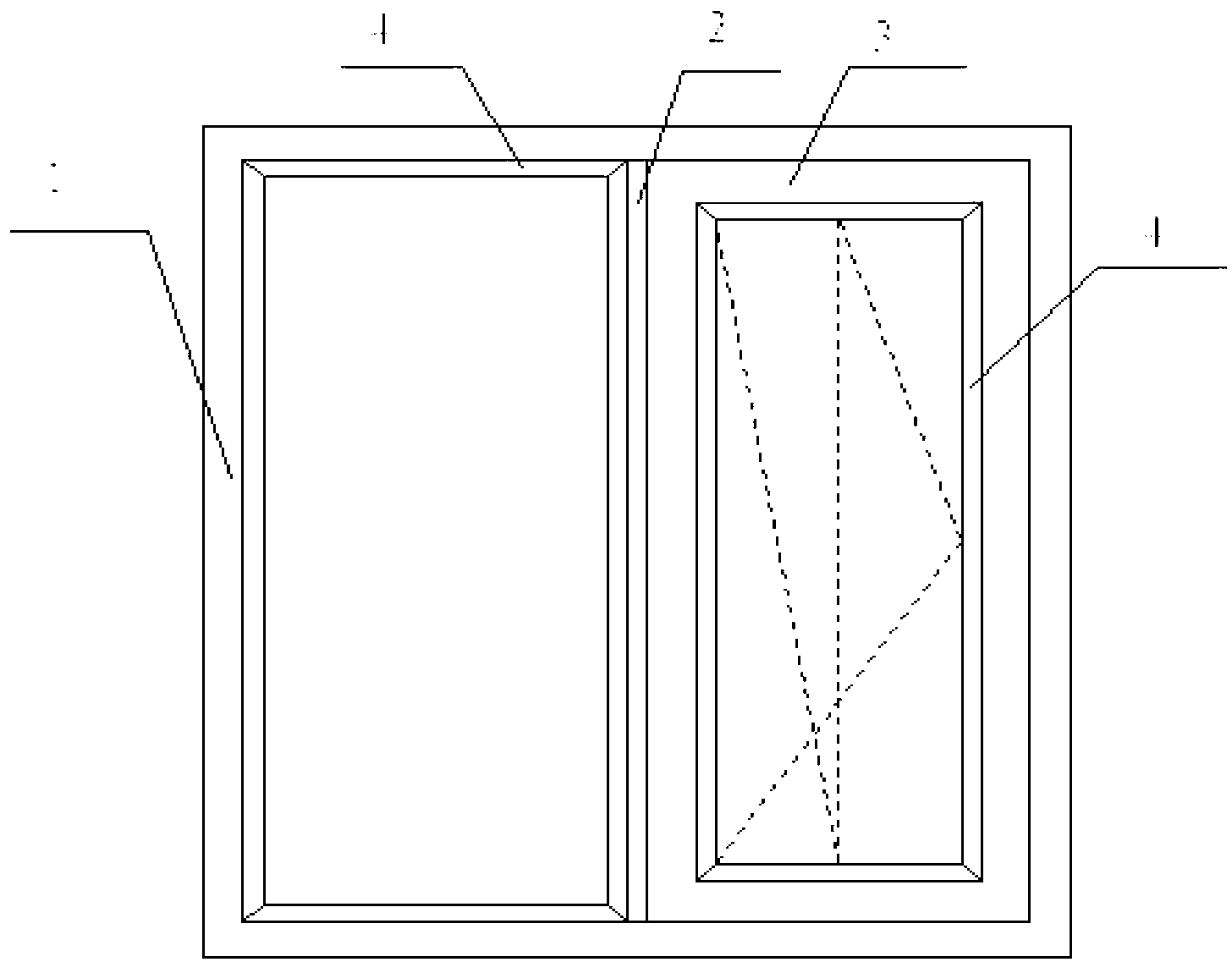

[0018] Specific Embodiment 1: In this embodiment, a wood-plastic glass door and window is composed of hollow wood-plastic profiles, glass, accessories and sealing strips, wherein the material of the hollow wood-plastic profiles is wood-plastic composite materials, and the hollow wood-plastic profiles are hollow structures. Wood-plastic profiles include frame profile 1, fan profile 3, mid-stiff profile 2 and bead profile 4, and accessories include hinges, rails, handles, door locks and stays.

[0019] The door and window profile preparation process in this embodiment adopts the fusion compound extrusion molding process, and its energy consumption is far lower than the production of aluminum profiles; the wood-plastic profiles can be connected together by gluing, welding or installing corner codes to obtain doors and windows, saving energy. Eliminate the cumbersome installation process of aluminum-wood, aluminum-plastic, wood-plastic-aluminum and other composite doors and windows...

specific Embodiment approach 2

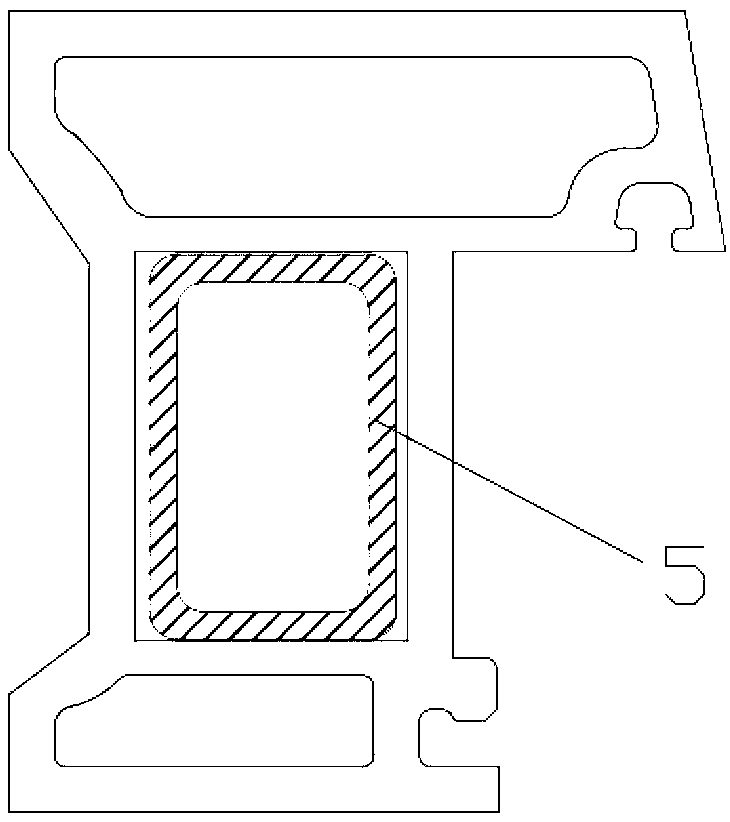

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the composition of the wood-plastic glass door and window also includes a reinforced inner lining 5, and the material of the reinforced inner lining 5 is steel lining, aluminum alloy lining, wood lining or bamboo lining . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 in that the sealing strip is made of modified polyvinyl chloride, EPDM rubber, thermoplastic elastomer or silicone rubber. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com