Ceramic plate with starlight effect and preparation method thereof

A ceramic and starlight technology, applied in the field of building materials, can solve the problems of dullness, high cracking rate and lack of texture on the surface, and achieve the effect of improving quality and overcoming dull color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] A method for preparing a ceramic plate with a starlight effect, which is used to prepare the above-mentioned ceramic plate with a starlight effect, the method comprising the following steps:

[0068] (1) Apply the glaze of the covering layer on the surface of the dried green body, and then apply the glaze of the basic colored layer on the glaze of the covering layer, and the thickness of the glaze of the basic colored layer is 2mm;

[0069] (2) Send the green body covered with two layers of glaze into the drying kiln for drying. The temperature in the drying kiln is 60-110°C and the humidity is 60%-99%;

[0070] (3) On the surface of the glazed green body after drying in step (2), apply the glaze of the soft light colored layer on the surface, and the thickness of the application is 2mm;

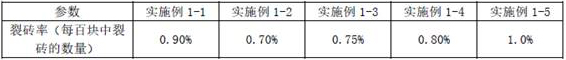

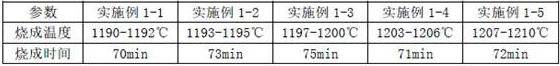

[0071] (4) Send it to the drying kiln again for drying, and then enter the kiln for firing. The firing temperature is 1190-1210°C, the firing cycle is 70-75min, and it is polished af...

Embodiment 2

[0136] The ceramic plate with starlight effect and its preparation method in this embodiment are basically the same as those in Embodiments 1-3, except that the raw material of the burnt-out dry particles does not contain ceramic glitter powder.

[0137] The surface of the obtained ceramic plate has high-brightness reflective points, but there are no reflective points in the small depressions, showing a shadow effect, which has a certain reflection effect on light. The ceramic tile can overcome the shortcomings of dull surface color to a certain extent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com