Method for manufacturing vegetarian meat and vegetarian meat

A technology for producing vegetarian and wheat, applied to a method and the field of vegetarian meat produced by said method, can solve the problems of consumption and excess energy, and achieve the effect of reducing raw material cost and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Example 1: Manufacture of flat gluten vegetarian meat with high water content

[0039] Washing process:

[0040] Add 45kg of water to a 5-horsepower type gluten washing machine, then add 3 bags of about 66kg of high-gluten flour as gluten washing powder, set the speed at 20rpm, stir back and forth for 30 seconds, and then stop stirring for 20 minutes.

[0041] The first tendon washing: set the speed at 20rpm, stir back and forth with 80kg water for 30 seconds, after 7.5 minutes, stop stirring and change the water.

[0042] The second to fifth gluten washing: set the speed at 30 rpm, stir back and forth with 80kg water for 30 seconds for 7.5 minutes, stop stirring and change the water, the total gluten washing time is 37.5 minutes, take out the wet wheat gluten for later use.

[0043] Seasoning process:

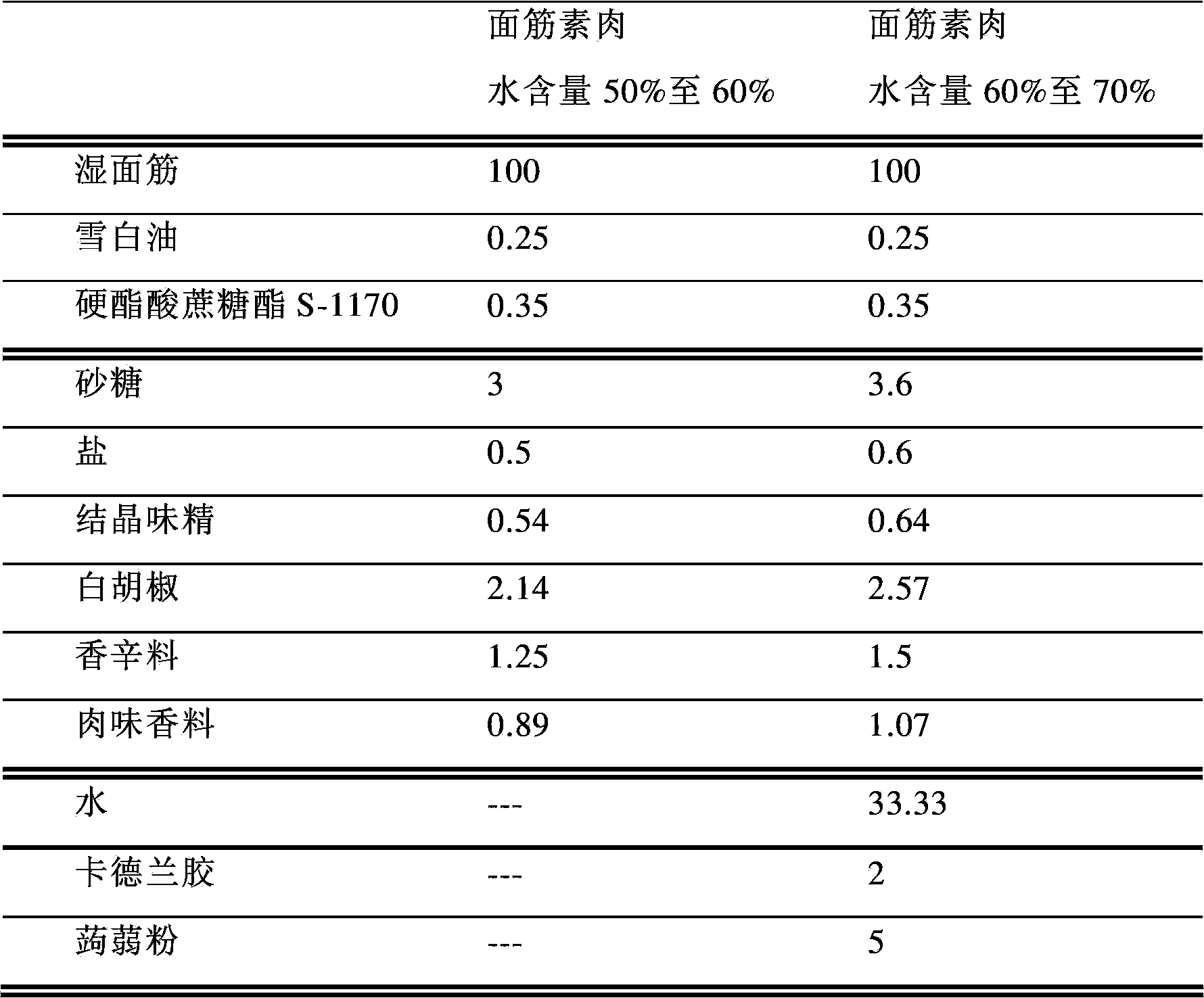

[0044] Prepare vegetarian meat according to the following table 1:

[0045] Table 1:

[0046]

[0047] Unit: parts by weight

[0048] (1) Preparation of gluten ...

Embodiment 2

[0075] Embodiment 2: the manufacture of high water content cylindrical gluten vegetarian meat

[0076] Washing process:

[0077] Add 45kg of water to a 5-horsepower intermediate factory-type gluten washing machine, then add 3 bags of about 66kg of high-gluten flour as gluten washing powder, set the speed at 20rpm, stir back and forth for 30 seconds, and then stop stirring for 20 minutes.

[0078] The first tendon washing: set the speed at 20rpm, stir back and forth with 80kg water for 30 seconds, after 7.5 minutes, stop stirring and change the water.

[0079] The second to fifth gluten washing: set the speed at 30 rpm, stir back and forth with 80kg water for 30 seconds for 7.5 minutes, stop stirring and change the water, the total gluten washing time is 37.5 minutes, take out the wet gluten for later use.

[0080] Seasoning process

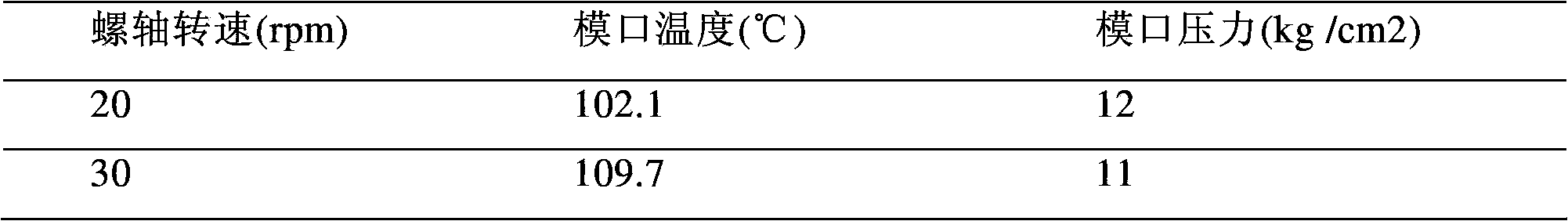

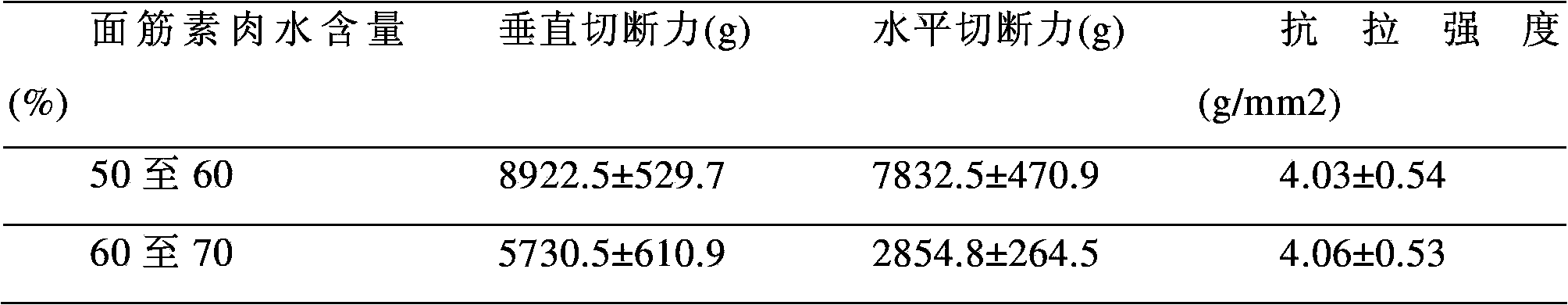

[0081] The formula of gluten vegetarian meat is shown in Table 5 below.

[0082] table 5:

[0083]

[0084] Unit: parts by weight

[0085...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com