Meat pounding machine of lean meatballs

A meat machine and lean meat technology, which is applied in the field of lean meat ball pounding machine devices, can solve problems such as lack of automation equipment, and achieve the effects of reducing the burden of manpower and material resources, high service life, and high frequency of beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

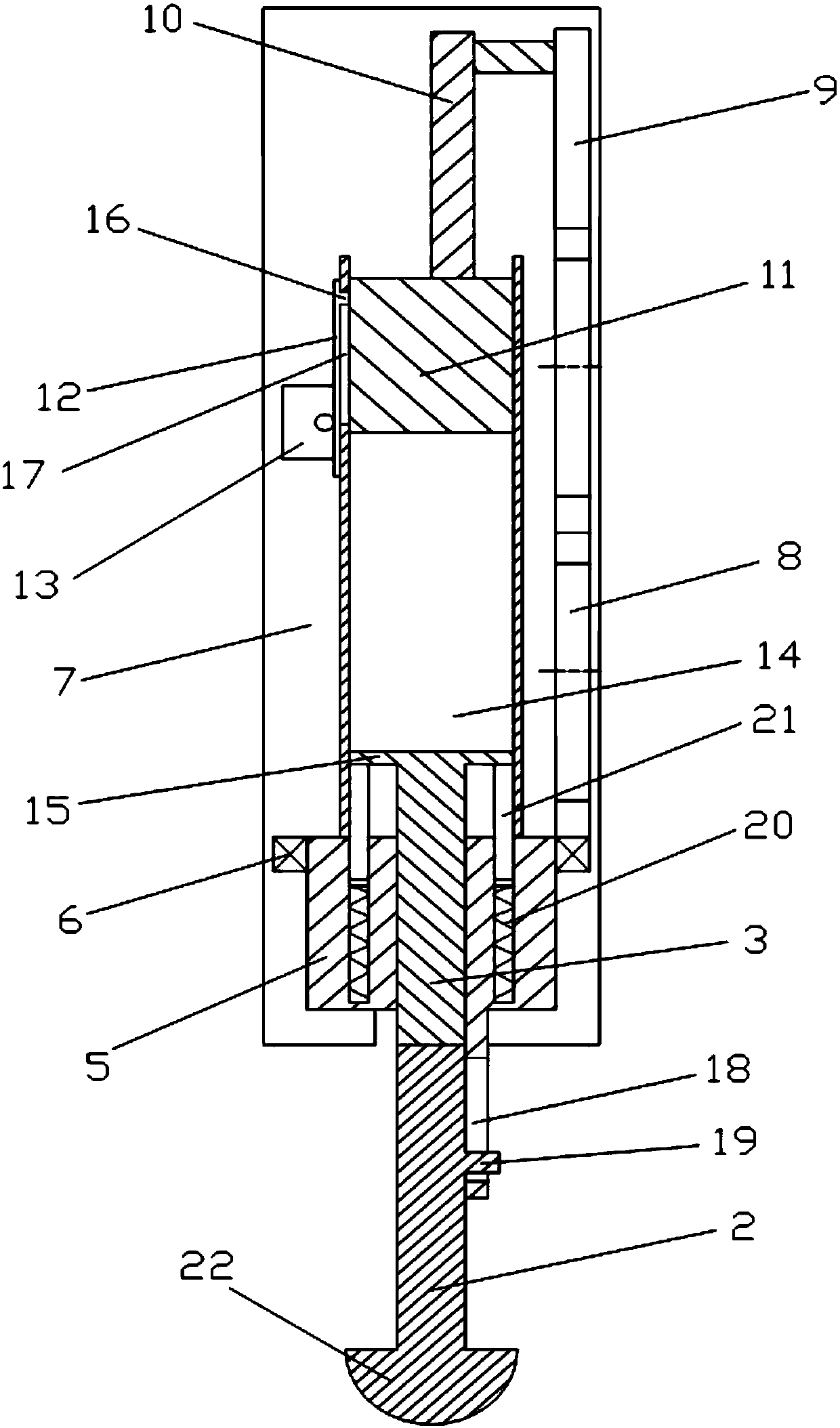

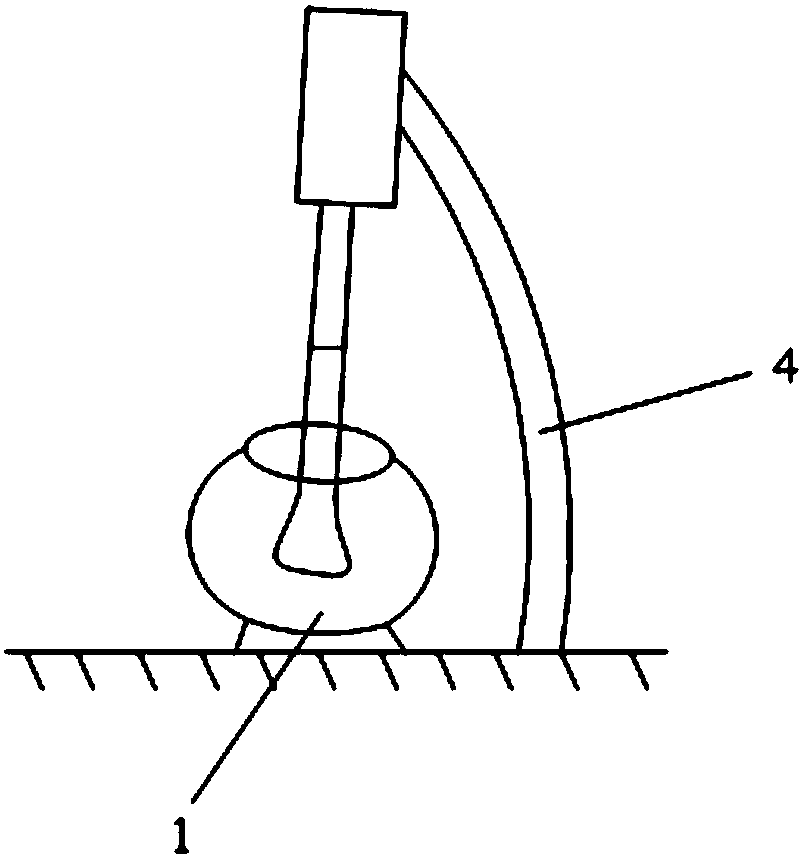

[0020] Such as Figure 1-Figure 2 As shown, a lean meatball pounding machine device includes a container seat 1 for holding raw materials, a hammer body 2 for impacting and pounding materials, an impact assembly that drives the hammer body 2 to repeatedly pound materials, and a mechanism that connects the hammer body 2 and the impact assembly. The connecting rod 3 is installed with the fixed seat 4 of the impact assembly, and the impact assembly includes the inner nest 5, the worm gear 6, the housing 7, the gear 8, the eccentric wheel 9, the eccentric rod 10, the piston 11, the rack 12, the motor 13 and the connecting rod 3, the shape and size of the fixed seat 4 are determined according to actual production needs, so it is not limited too much here.

[0021] The housing 7 is provided with a cavity body 14 for the reciprocating movement of the piston 11. The two ends of the cavity body 14 are provided with openings. On the inner side, the inner nest 5 is arranged on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com