Meat beating and mincing device

A technology of mincing and meat, applied in the direction of tenderizing meat, processing meat, softening meat by beating, etc. It can solve the problems of complex structure and high energy consumption, and achieve the effect of good taste and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

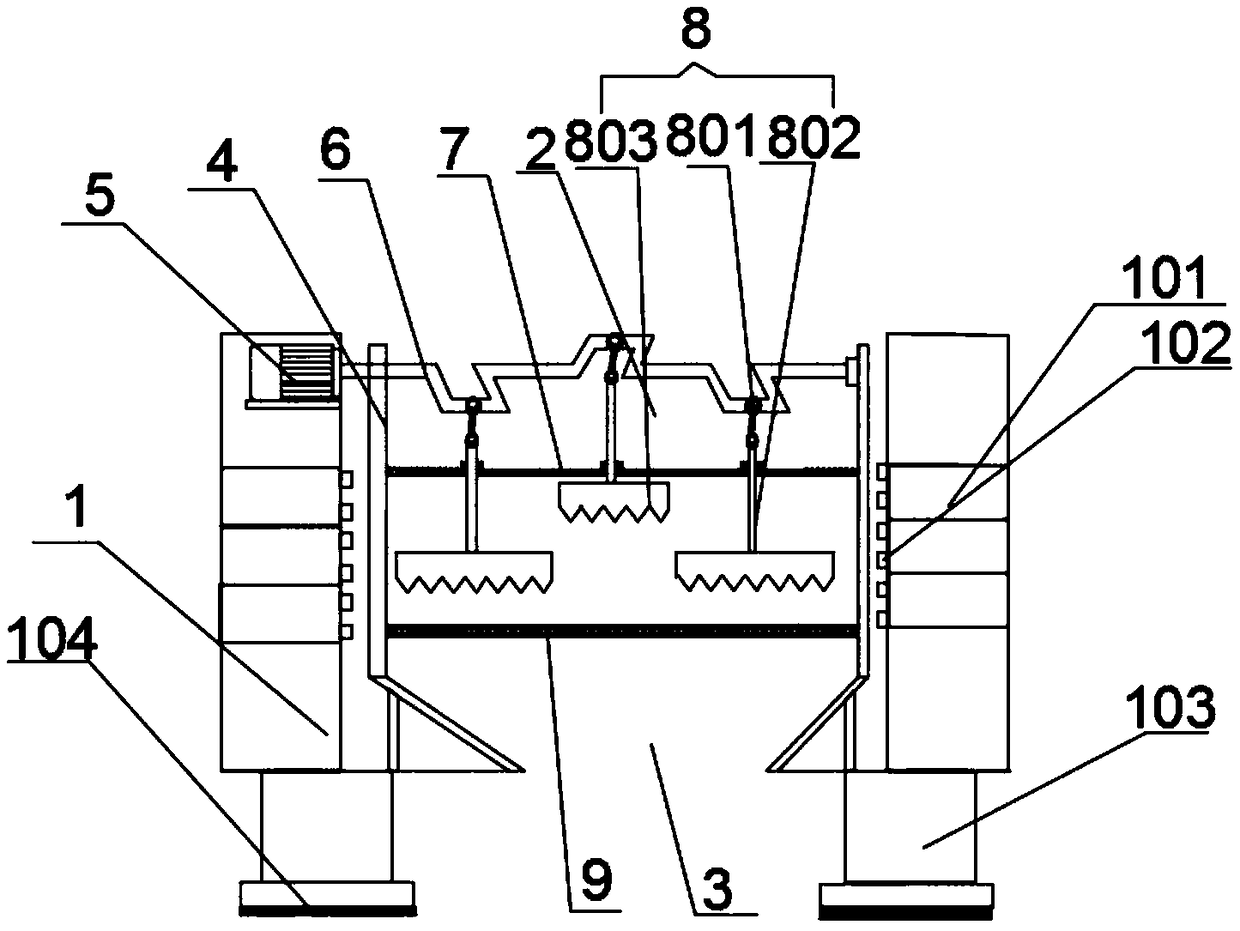

[0027] Such as figure 1 As shown, the present embodiment provides a meat beating and grinding device, which includes a device housing and meat inlets and meat outlets located above and below the device housing. Beating the frame, the inner wall of the device shell is fixed with a first motor, a crankshaft is arranged in the said beating frame and just below the meat inlet, a guide rod is arranged under the crankshaft, and one end of the crankshaft passes through the beating The frame is connected with the first motor, and the other end of the crankshaft is flexibly connected with the beating frame. The crankshaft is provided with three minced meat beating plates that reciprocate up and down through the guide sleeve rod. The minced meat beating plates include a Connecting rod 1, connecting rod 2 hinged with connecting rod 1 and the toothed crushing plate connected with connecting rod 2, the connecting rod 2 passes through the guide sleeve rod, under the minced meat beating plat...

Embodiment 2

[0030] Such as figure 1 As shown, in order to ensure the meat quality of the present invention during the beating process, the meat will not deteriorate due to high temperature during the beating process. This embodiment has been further improved on the basis of Example 1, specifically 4 dry ice device cavities are respectively provided on both sides of the device housing, and 8 adjustable spray nozzles connected with the dry ice device cavities are respectively provided on the inner wall of the device housing. Too high will affect the meat quality, so dry ice is installed in the cavity of the dry ice device, and the temperature inside the device is cooled through the adjustable spray nozzle to ensure the quality of the meat during the process of beating and crushing.

Embodiment 3

[0032] Such as figure 1As shown, in order to make the present invention more convenient to use, easier to clean, and to inhibit the growth of bacteria, this embodiment has made further improvements on the basis of Embodiment 2, specifically: a There are two supporting columns, and a silica gel pad is arranged under the supporting column, which ensures that no large noise will be generated due to the impact of the supporting column on the ground during the beating process. At the same time, the silica gel pad has a shock-absorbing effect. The shell of the pulverizer is provided with a PLC controller and a control panel, the frequency converter is electrically connected to the PLC controller, and the PLC controller is electrically connected to the control panel, and the speed of the motor can be controlled by the frequency converter to control the gear. The speed at which the meat is beaten by the shape crushing plate makes the meat quality more elastic. The filter plate is mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com