Tumbling device for pickling products

A kind of equipment and product technology, applied in the field of rolling and kneading equipment, can solve the problems of a large amount of manpower, meat product flavoring work that cannot meet the expected requirements, and time-consuming, etc., to achieve the goal of increasing yield, improving product elasticity, and improving binding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

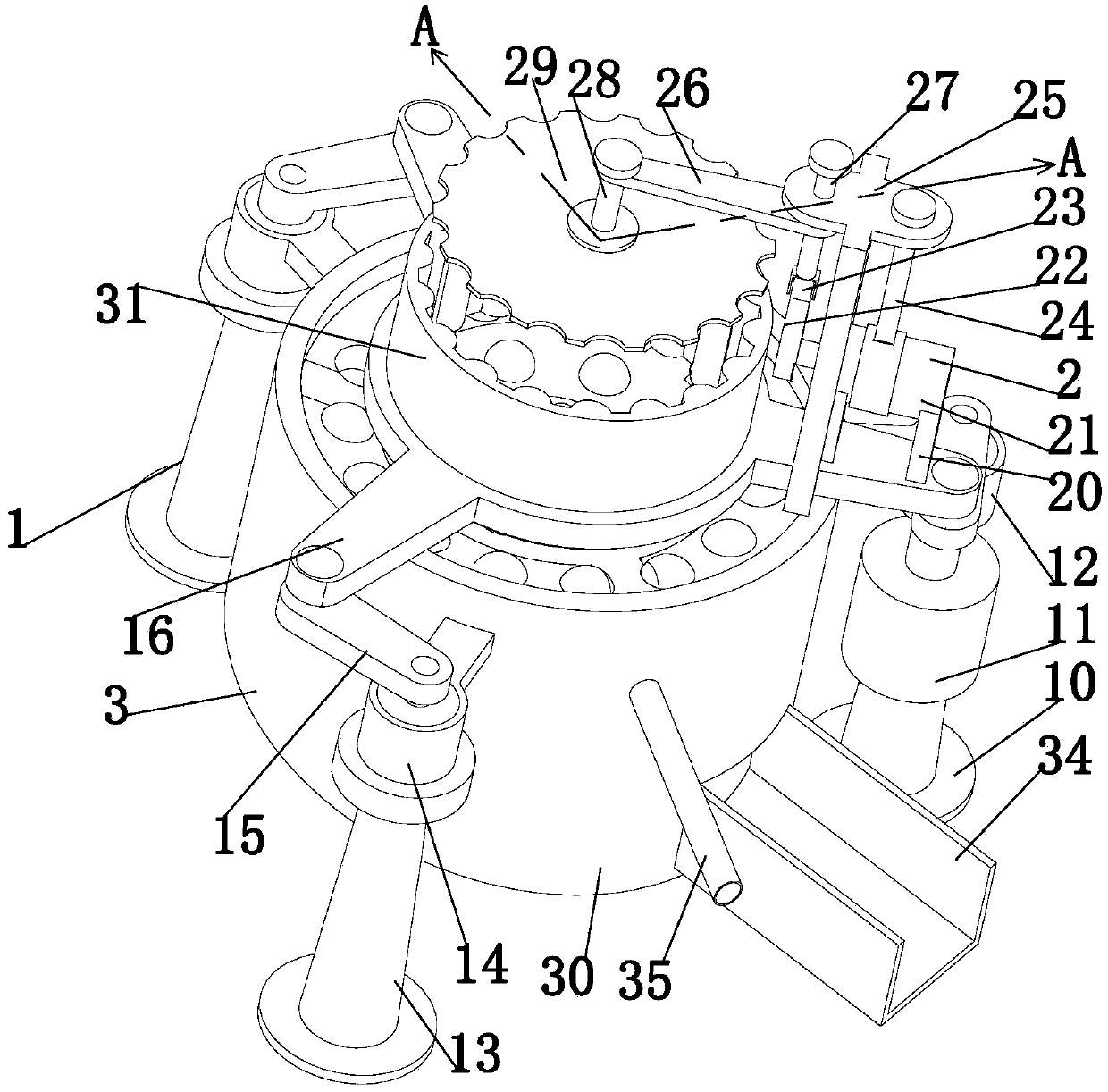

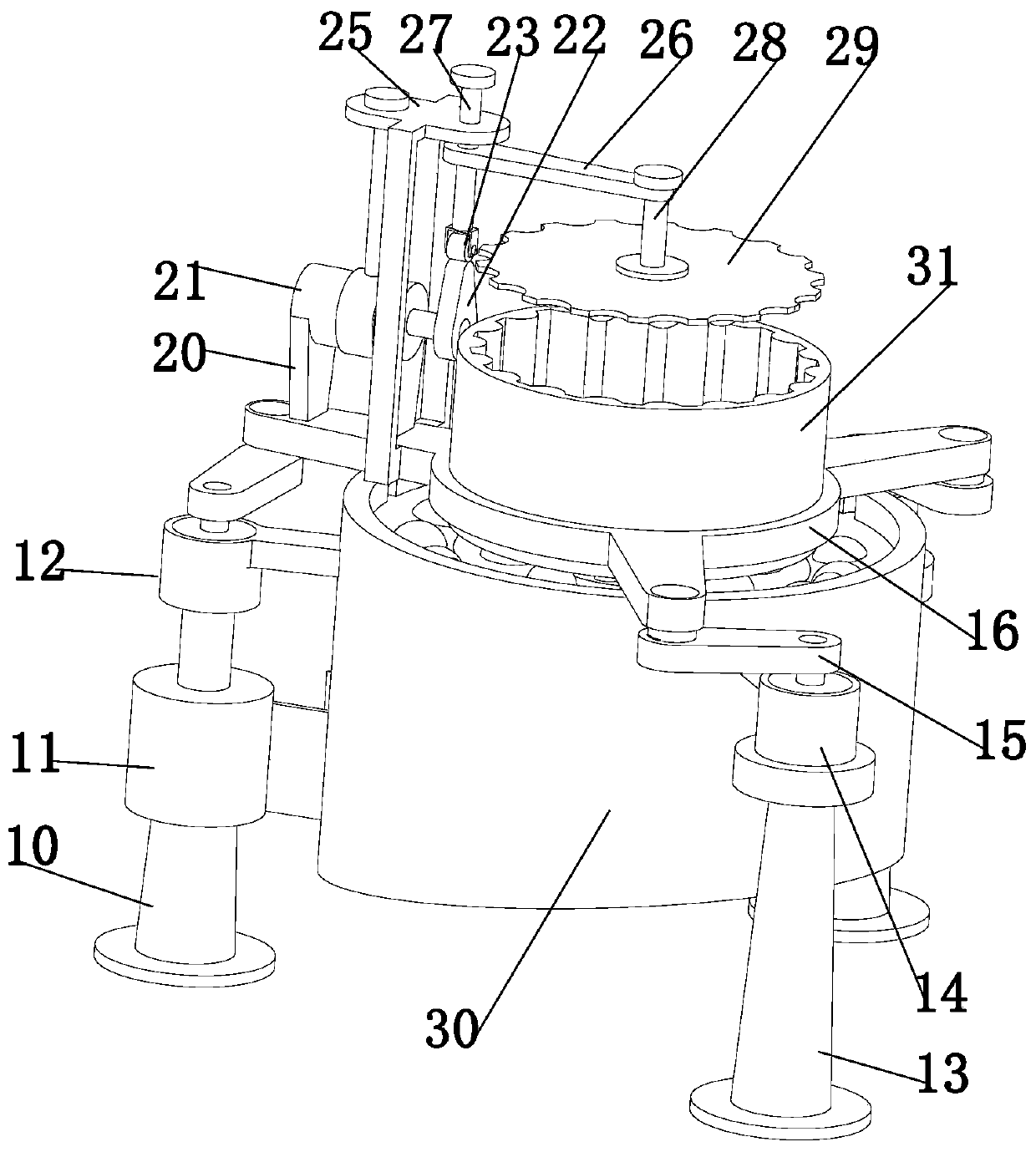

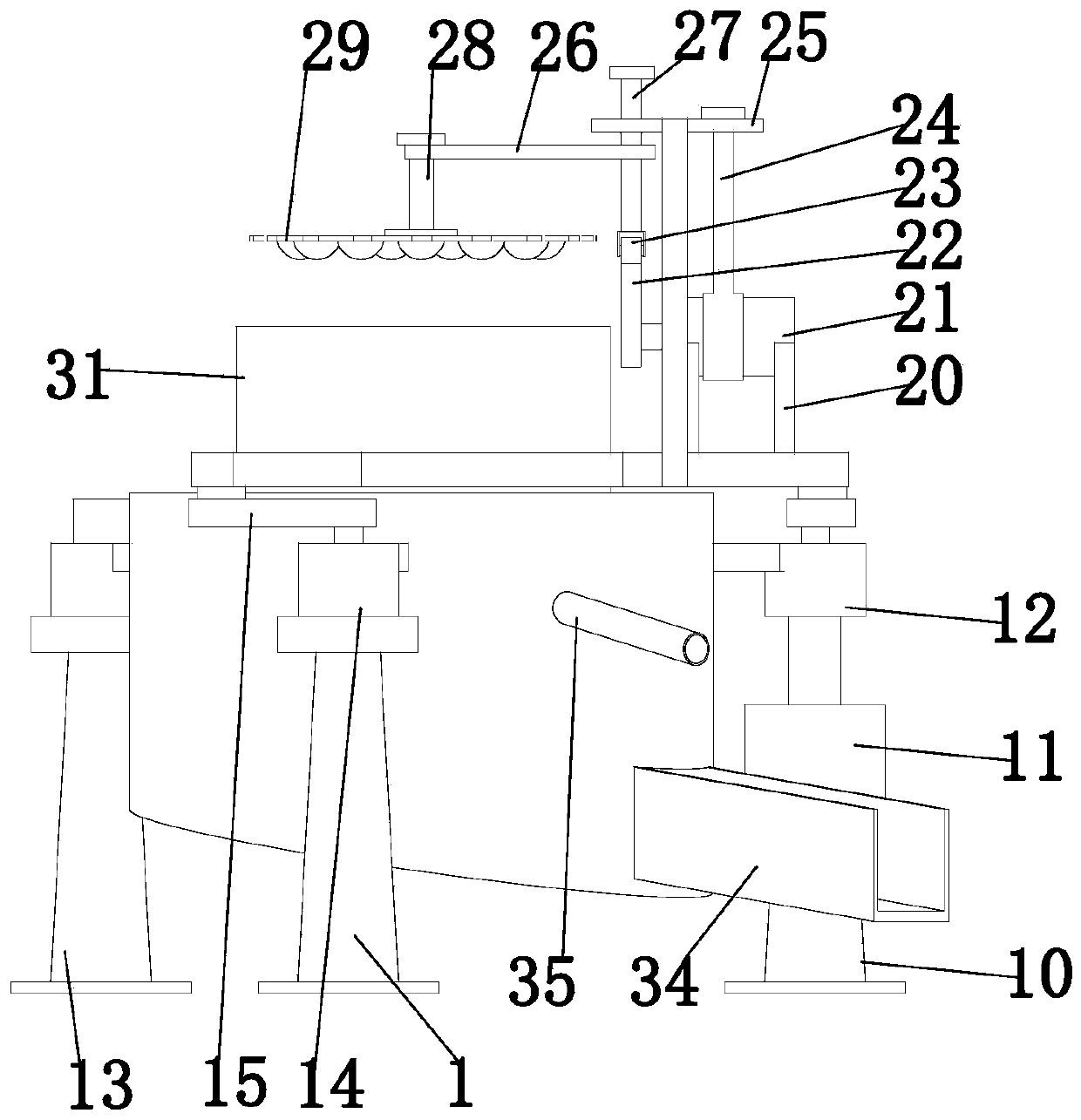

[0025] Such as Figure 1 to Figure 4 As shown, a tumbling device for pickled products includes an actuator 1, a cam mechanism 2, and a tumbling mechanism 3. A cam mechanism 2 is installed above the actuator 1, and a roller is installed in the middle of the actuator 1. kneading mechanism 3, and the tumbling mechanism 3 is connected with the cam mechanism 2 through a movable manner, wherein:

[0026] The cam mechanism 2 includes a motor bracket 20, a driving motor 21, a cam 22, a roller 23, an auxiliary stabilizing bracket 24, a crank connecting rod frame 25, a sliding crank connecting rod 26, a slide rod 27, a reciprocating rod 28 and a beating cover. Plate 29, the motor bracket 20 is installed on the upper end surface of the actuator 1, the motor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com