Vinasse pickled Chinese sauerkraut with blood fat reducing effect and making method thereof

A production method and blood lipid-lowering technology, which are applied in climate change adaptation, food science and other directions, can solve the problems of uneven application of distiller's grains, long fermentation period of sauerkraut, and retention of sauerkraut aroma, so as to improve comprehensive economic benefits, improve bioavailability, Total cholesterol lowering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of sauerkraut with hypolipidemic effect and preparation method thereof

[0034] 1. Raw material pretreatment: select fresh vegetables, the vegetables are cabbage, first select the inferior vegetables and inferior vegetables, and then wash the selected qualified vegetables, clean them and drain them, and finally remove the petioles and vegetables. The leaves can be cut into small sections; in the cleaning process, an advanced bubbling cleaning line can be used to replace the traditional manual cleaning, which can improve production efficiency and cleaning effect.

[0035] 2. Drying treatment: the obtained raw materials are subjected to dehydration treatment, and dried with hot air to 7-80% dryness to obtain a drying material, that is, drying until the moisture content is controlled between 15-30%; The hot air drying adopts the hot air drying production line for automatic dehydration treatment, and the hot air temperature is controlled between 32 and 35 °C; the hot...

Embodiment 2

[0046] A kind of sauerkraut with hypolipidemic effect and preparation method thereof

[0047] 1. Raw material pretreatment: select fresh vegetables, the vegetables are cabbage, first select the inferior vegetables and inferior vegetables, and then wash the selected qualified vegetables, clean them and drain them, and finally remove the petioles and vegetables. The leaves can be cut into sections; in the cleaning process, an advanced bubbling cleaning line can be used to replace the traditional manual cleaning, which can improve production efficiency and cleaning effect.

[0048] 2. Drying treatment: the obtained raw materials are subjected to dehydration treatment, and dried with hot air to 7-80% dryness to obtain a drying material, that is, drying until the moisture content is controlled between 15-30%; The hot air drying adopts the hot air drying production line for automatic dehydration treatment, and the hot air temperature is controlled between 32 and 35 °C; the hot air d...

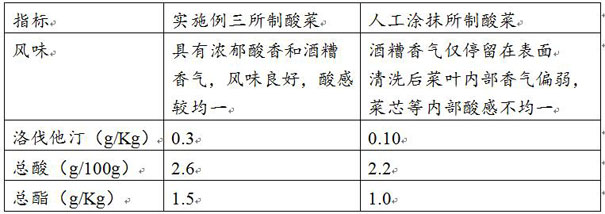

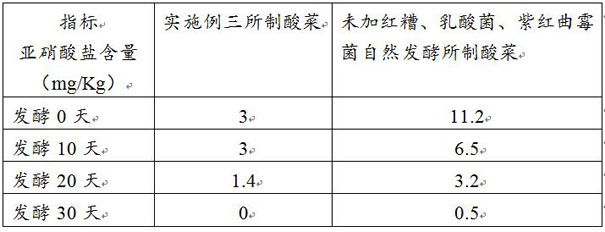

Embodiment 3

[0059] A kind of sauerkraut with hypolipidemic effect and preparation method thereof

[0060] 1. Raw material pretreatment: select fresh vegetables, the vegetables are cabbage, first select the inferior vegetables and inferior vegetables, and then wash the selected qualified vegetables, clean them and drain them, and finally remove the petioles and vegetables. The leaves can be cut into sections; in the cleaning process, an advanced bubbling cleaning line can be used to replace the traditional manual cleaning, which can improve production efficiency and cleaning effect.

[0061] 2. Drying treatment: the obtained raw materials are subjected to dehydration treatment, and dried with hot air to 7-80% dryness to obtain a drying material, that is, drying until the moisture content is controlled between 15-30%; The hot air drying adopts the hot air drying production line for automatic dehydration treatment, and the hot air temperature is controlled between 32 and 35 °C; the hot air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com