Making method and device of puff beef steak

The technology of a preparation device and a preparation method is applied in the field of preparation of crispy steak, and can solve the problems such as the inability to accurately grasp the frying time and the frying temperature, difficulty in enjoying the best taste of high-grade steak, and difficulty in gaining favor from middle and high-end consumers, and the like. To achieve the effect of chewy taste, easy to make, and well-made

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The invention provides a puff pastry steak, which comprises puff pastry, sandwich sauce and sirloin steak wrapped sequentially from the outside to the inside.

Embodiment 2

[0060] A kind of preparation method of puff pastry steak,

[0061] S1. How to make puff pastry:

[0062] The puff pastry is made by mixing 25 parts of flour, 15 parts of warm water, 5 parts of sugar, 5 parts of salt, 15 parts of olive oil and 5 parts of dry yeast, all of which are parts by weight;

[0063] Put 25 parts of flour in the container, add 5 parts of salt and mix the flour and salt evenly by stirring;

[0064] Mix 5 parts dry yeast with 5 parts sugar and add warm water to activate the yeast;

[0065] After the yeast mixture bubbles, pour the yeast into the above flour and salt and knead the dough;

[0066] Knead the olive oil into the dough three times; until the dough is kneaded until the surface is smooth, cover it with a wet towel and let it rise for 30-60 minutes;

[0067] Roll out the proofed dough to make a pie crust and fold it repeatedly;

[0068] Roll the folded dough into a round cake and wrap it in a sealed package with plastic wrap for refrigeration; ...

Embodiment 3

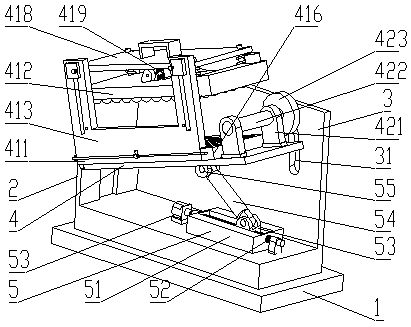

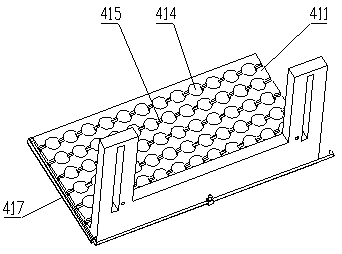

[0087] see figure 1 and figure 2 , a preparation device for puff pastry steak, comprising a base 1, a support plate 2 vertically arranged on the top of the base 1, and a back plate 3 perpendicular to the support plate, the support plate 2 is hinged to one end of a vibrating table 4, and the vibrating table 4 The bottom is connected to the bottom platform 1 through the driving mechanism 5, and the hammer pressing mechanism 410 and the guiding mechanism 420 are set on the vibration table 4;

[0088] The drive mechanism 5 includes a guide rail 51 arranged on the upper surface of the base 1, a screw mandrel 52 runs through the guide rail 51, and the screw mandrel 52 is driven to rotate by a driving motor arranged at one end of the guide rail 51, and the screw mandrel 52 is screwed to the lower slider 53, and Slider 53 is arranged on guide rail 51, is connected with guide rail 51 slidingly, and the lower end of lower slider 53 top hinged connecting rod 54; Fixed connection at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com