Food processing detection device based on big data cloud platform and use method of device

A food processing and detection device technology, applied in the field of food processing, can solve problems such as poor taste, loose meatballs, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

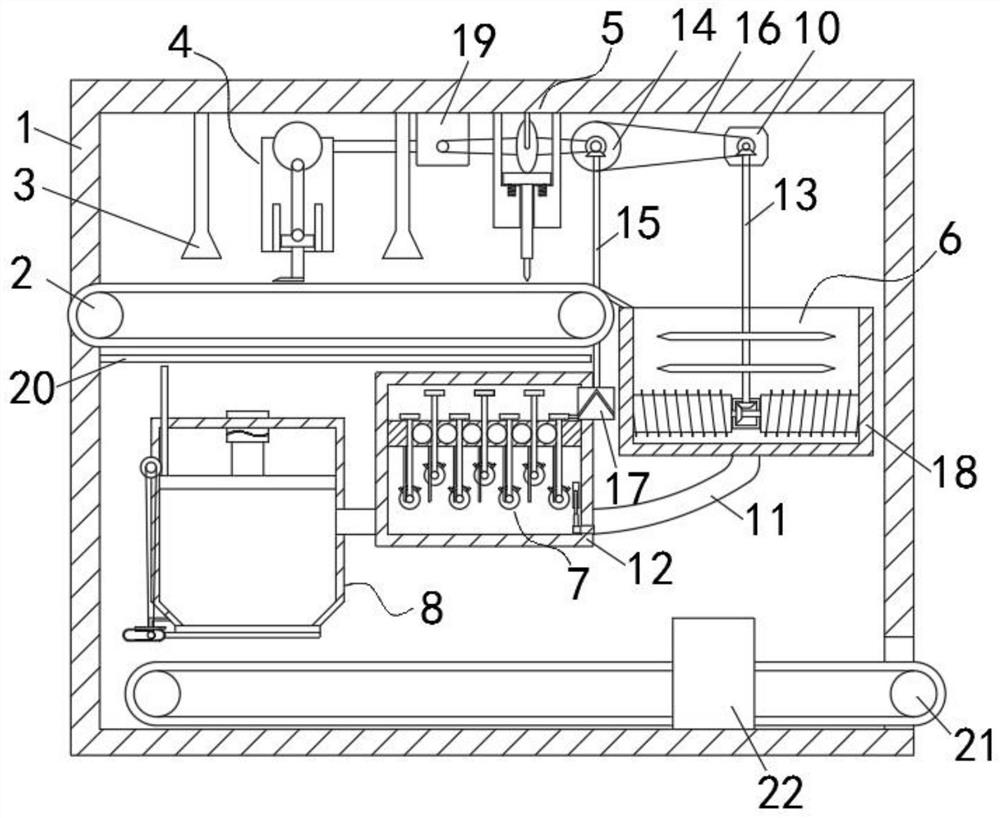

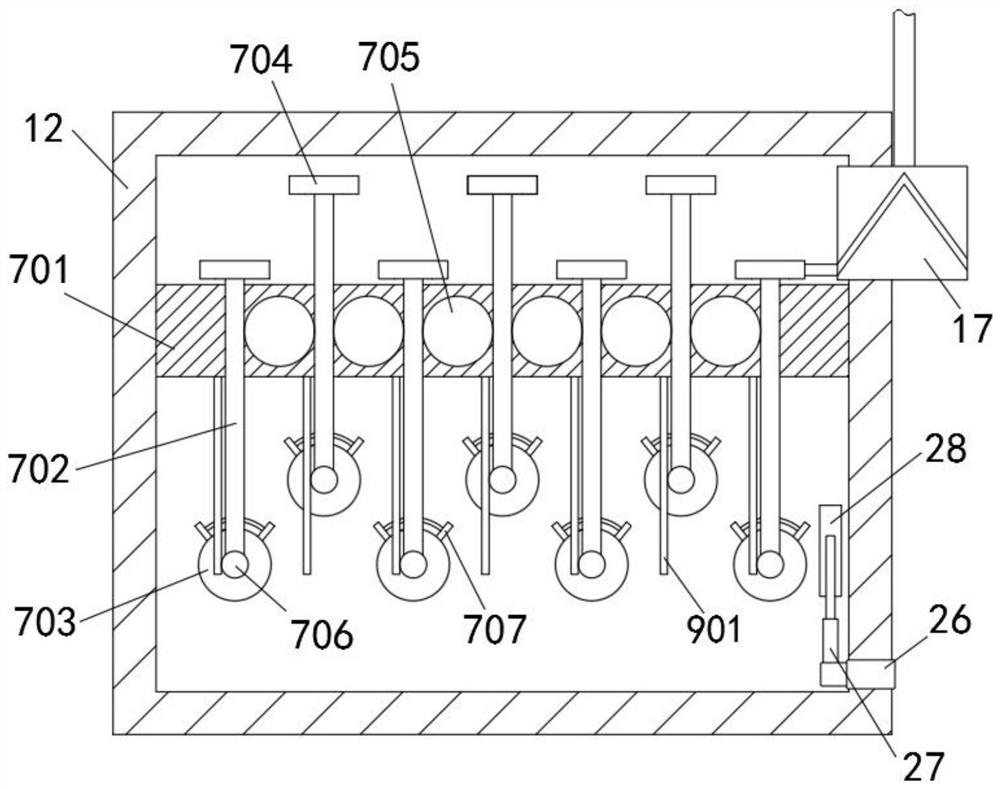

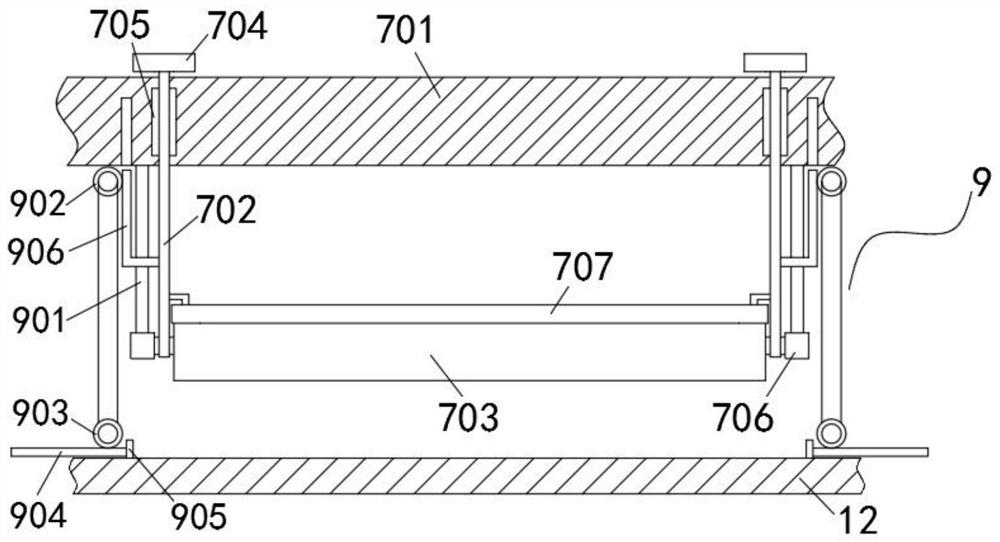

[0045] see Figure 1-11 , the present invention provides a technical solution: a food processing detection device based on a big data cloud platform, including a processing detection box 1, a first conveyor belt 2 is provided on the left side of the top of the processing detection box 1, and a bottom of the first conveyor belt 2 is provided. There is a water receiving tray 20, two nozzles are fixed on the top of the first conveyor belt 2, and a nozzle 3 is fixed on the bottom of the nozzle. Block assembly 5, the right side of the first conveyor belt 2 is provided with a meat grinding box 18, the meat grinding box 18 is provided with a cutting and mixing assembly 6, the bottom of the meat grinding box 18 is communicated with and fixed with a conveying pipe 11, and the left end of the conveying pipe 11 is connected and fixed There is a beating processing box 12, the inside of the beating processing box 12 is provided with a beating assembly 7, the front and rear sides of the bea...

Embodiment 2

[0068] Under the situation that other parts are all the same as the first embodiment, the difference between this embodiment and the first embodiment is that the pre-cut block assembly 5 includes a second fixing plate 501, and the second fixing plate 501 is fixed to the top wall of the processing inspection box 1 connection, the top of the second fixed plate 501 is provided with a lifting groove, and an elliptical block 502 is arranged in the lifting groove, and the elliptical block 502 is rotatably connected with the top wall of the processing detection box 1, and the rear side of the elliptical block 502 is fixed with a linkage gear, and the linkage gear It is linked with the rotating shaft on the front side of the reduction gear 14 and the connecting shaft on the front side of the reduction box 19. The bottom of the second fixed plate 501 is slidingly connected with a cutting rod 503, and the bottom of the cutting rod 503 is fixed with a cutting knife 504. A pressing piece 5...

Embodiment 3

[0071] In the case that the other parts are the same as in the first embodiment, the difference between the present embodiment and the first embodiment is that the turning assembly 4 includes a first fixing plate 401, and the first fixing plate 401 is fixedly connected with the top wall of the processing inspection box 1 , the front side of the first fixed plate 401 is rotatably connected with a rotating disk 402, and the center of the rotating disk 402 is fixed with a rotating shaft. A hinged rod is connected, the other end of the hinged rod is hinged with a sliding block, the other end of the sliding block is fixed with a vertical elevating rod 403, the bottom end of the elevating rod 403 is fixed with a horizontal flipping plate 404, the left and right sides of the first fixed plate 401 Slide bars 405 are fixed on both sides, and the slide blocks are slidably connected with the slide bars.

[0072] The output shaft of the motor 10 reduces the rotating speed twice through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com