Auxiliary equipment used for mutton processing

A kind of auxiliary equipment, mutton technology, applied in the field of mutton processing, can solve the problem of large consumption, achieve the effect of constant size, improved work efficiency, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

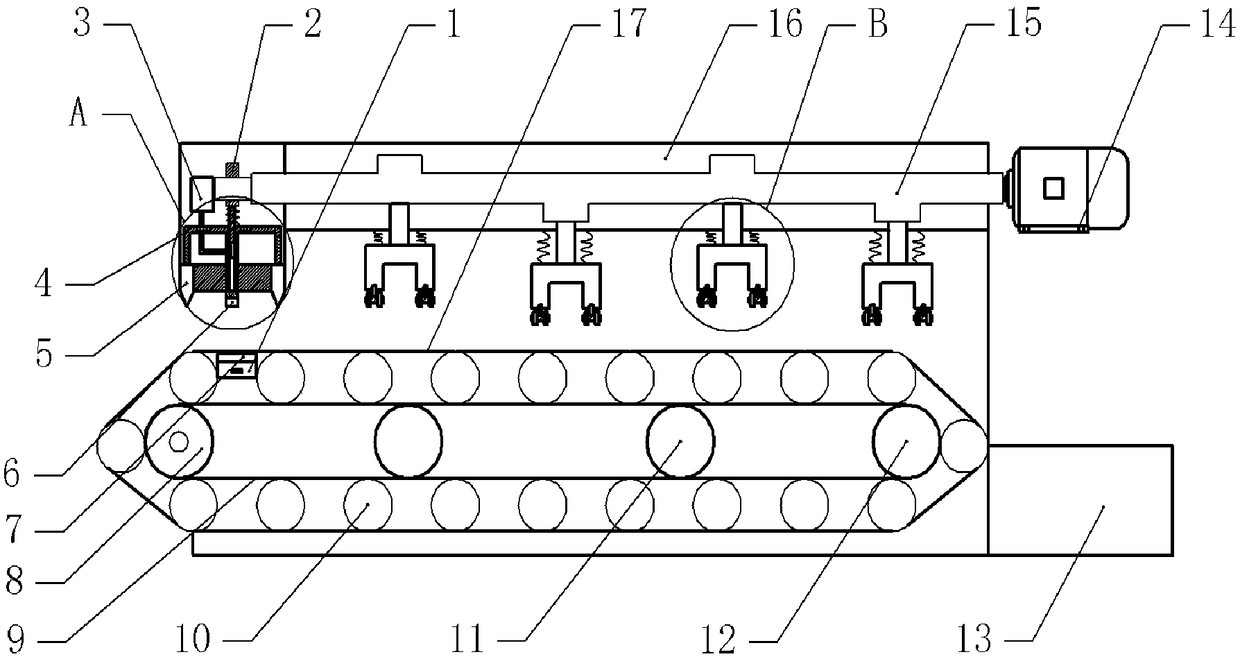

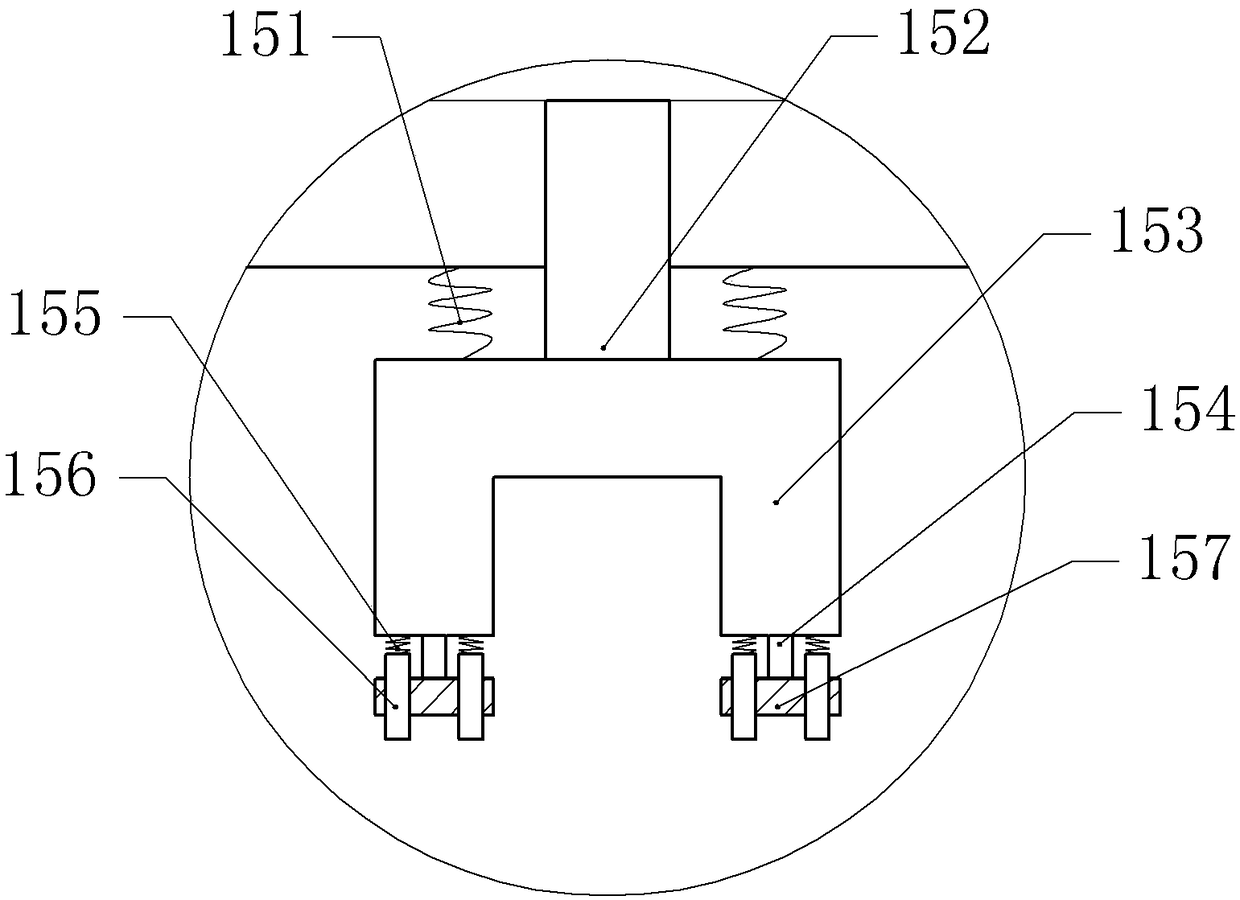

[0023] Basic as attached figure 1 As shown, a mutton processing equipment includes a frame 16, a transmission mechanism installed on the frame 16, a cutting mechanism and a knocking mechanism.

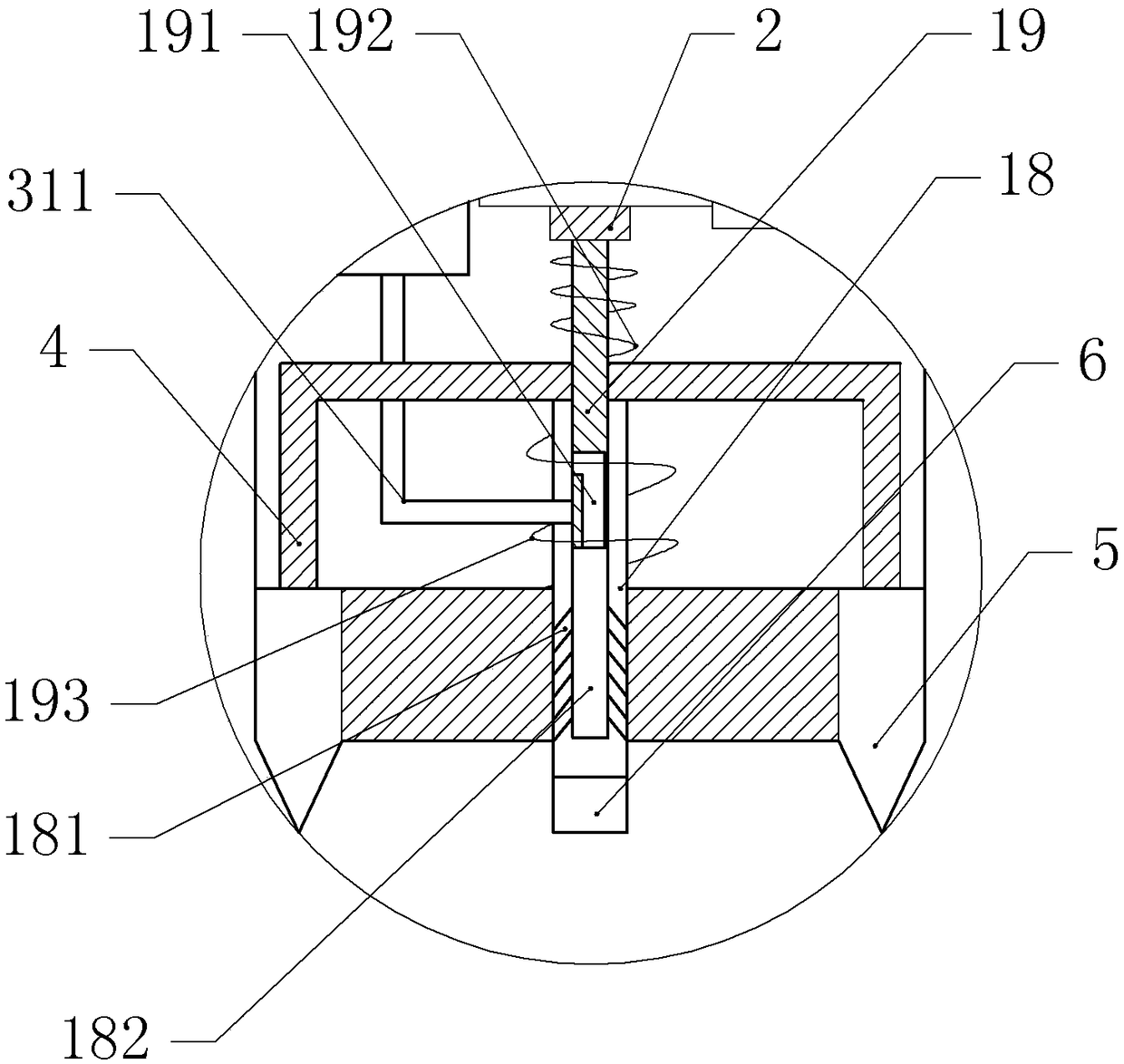

[0024] The transmission mechanism includes a driving roller 8, a driven roller 12 and a conveyor belt 9 connecting the driving roller 8 and the driven roller 12. The conveyor belt 9 is supported by two supporting rollers 11, and the driving roller 8 is driven by a second motor. A plurality of conveying rollers 10 are hinged on the conveyor belt 9, and a conveying plate 17 is hinged on the conveying roller 10. Two adjacent conveying plates 17 are hinged to each other. Electromagnets 22 are fixed in the conveying plates 17, and a fixed plate 7 is fixed on the frame 16. , the electric control box 1 is fixed on the fixed plate 7, and the electric control box 1 includes a double pole double throw switch 20, some wires 21 and a power supply, and the power supply, the wire 21, the double pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com