Pickling liquid injector

An injection device and pickling liquid technology, applied in the direction of softening meat by injection, processing meat by injection, preserving meat/fish with liquid, etc., can solve the problems of complex composition, high cost, and large resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, examples of the present invention will be described.

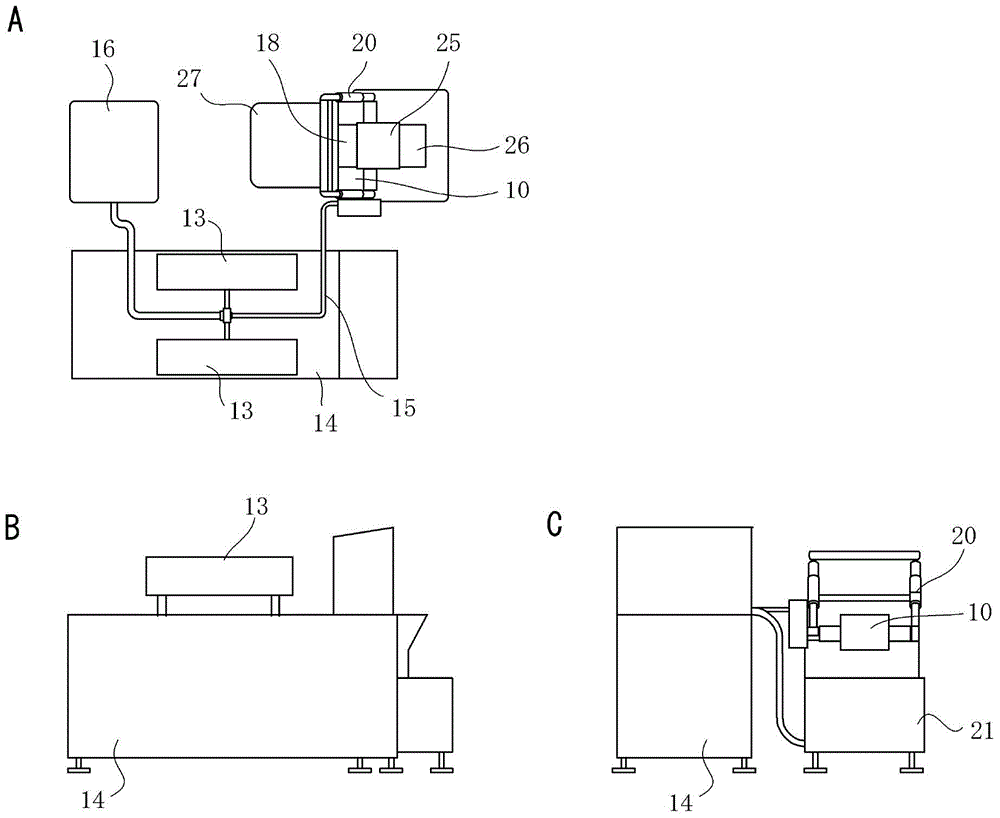

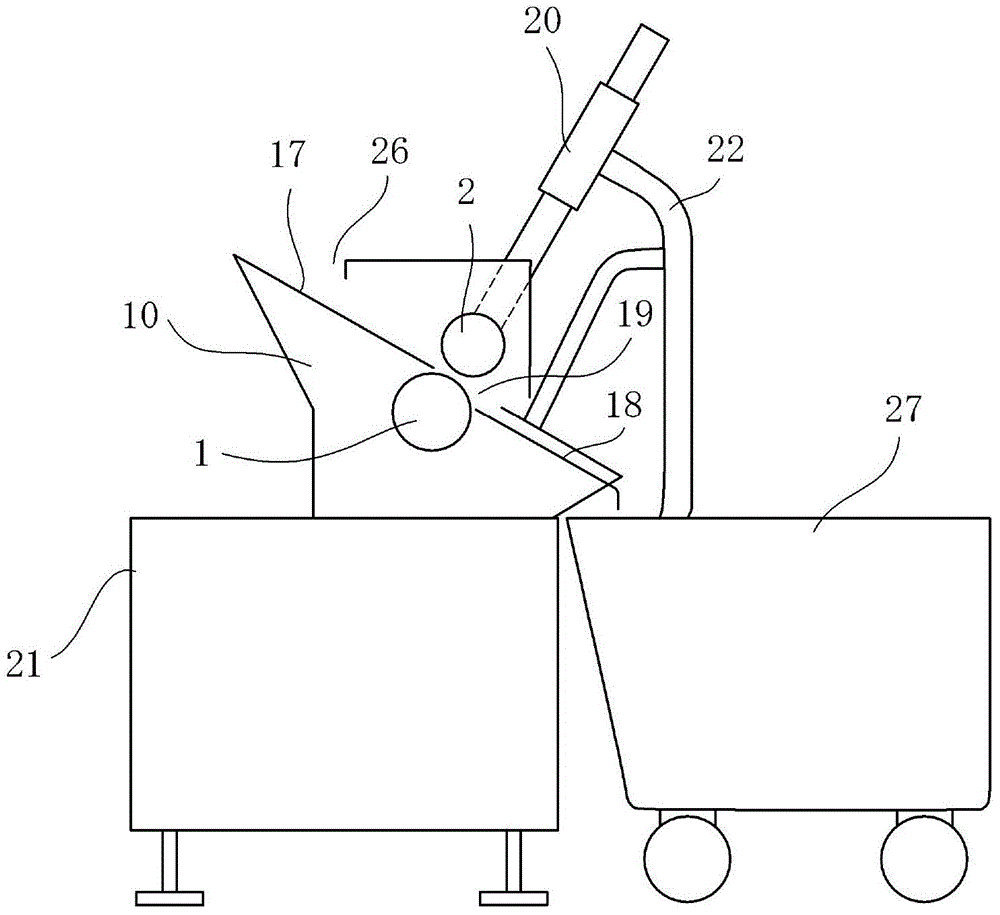

[0025] figure 1 denotes the pickling solution injection device according to the present invention. Such as figure 2 As shown, in this injection device, a pickling liquid discharge roller 1 is combined with a counter roller 2 .

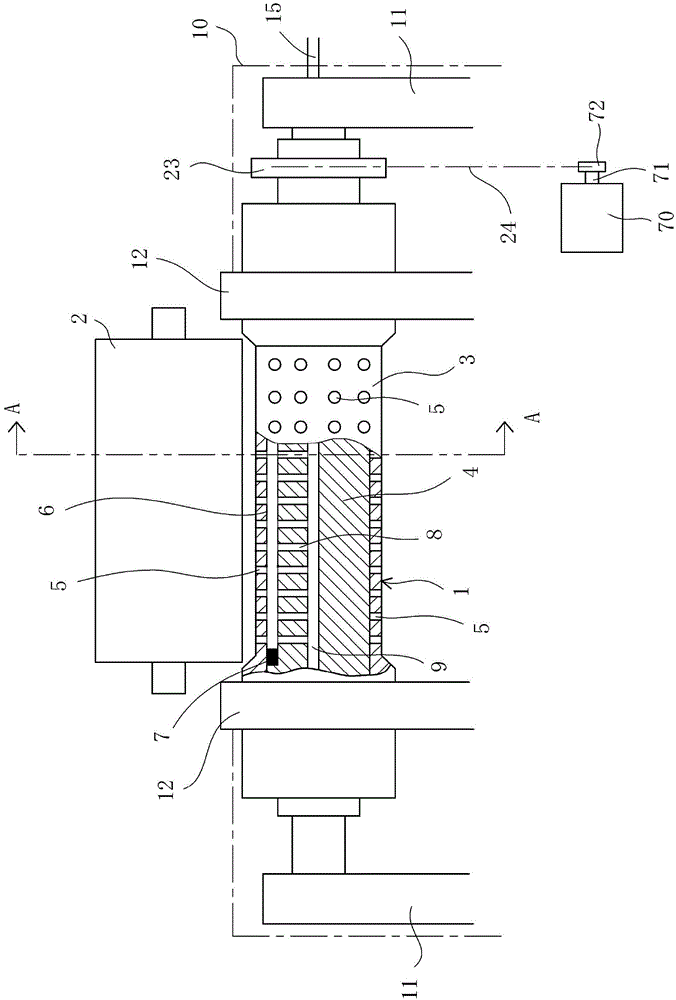

[0026] Such as image 3 and Figure 4 As shown, the discharge roller 1 has a cylindrical rotating body 3 and a cylindrical fixed body 4 . The rotating body 3 is fitted on the outer peripheral surface of the fixed body 4 . The sealing material 7 is provided between the rotating body 3 and the fixed body 4, and seals between the rotating body 3 and the fixing body 4 by the sealing material. The ejection roll 1 extends horizontally.

[0027] A plurality of small holes 5 are formed on the outer peripheral surface of the rotating body 3 . A groove 6 is formed on the outer peripheral surface of the fixed body 4 . A flow path is formed in the fixed body 4 . The small hole 5 extends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com