Impurity separation treatment equipment for building waste

A technology for separation and treatment of construction waste, applied in solid separation, grain treatment, screening, etc., which can solve the problems of heavy workload and slow collection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

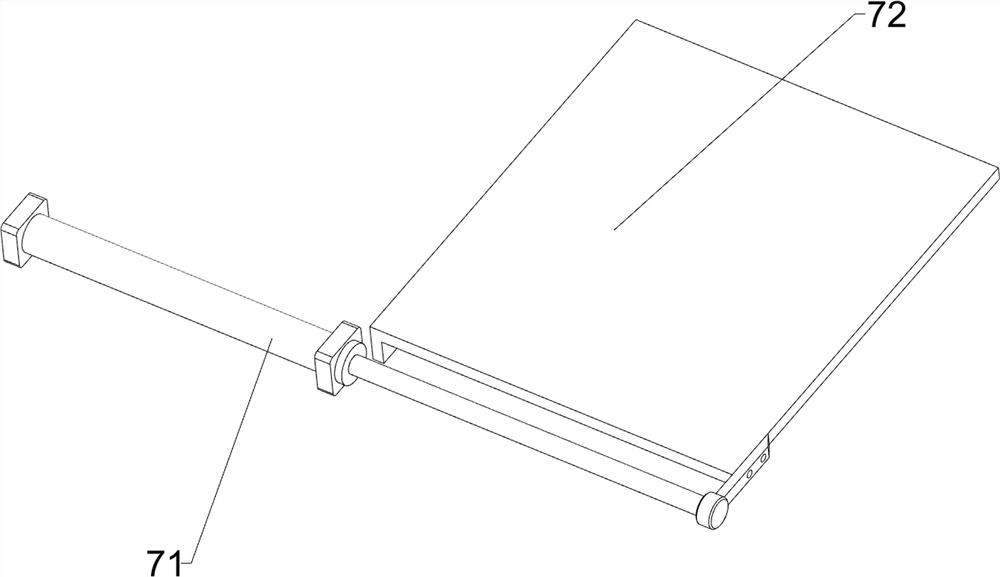

[0035] Impurity separation treatment equipment for building waste, such as Figure 1-9 As shown, a support frame 1, a housing 2, a screen 3, a pulverizing mechanism 4, a screening mechanism 5, a transfer mechanism 6, and a pusher 7 are provided, and the top portion of the support frame 1 is provided, and the housing 2 is inside the right side. The sliding type is provided with a screen 3, and a pulverizing mechanism 4 is provided on the right side of the housing 2, and the screen 3 and the pulverizing mechanism 4 are provided with a screening mechanism 5, and the housing 2 is provided with a transport mechanism 6, and the housing 2 is provided. There is a push mechanism 7.

[0036] The pulverizing mechanism 4 includes a first motor 40, a rotating shaft 41, a first gear 42, and a crushing roller 43, and a first motor 40 is provided on the right side of the housing 2, and the axis of the housing 2 has a rotation shaft 41, The output shaft of the first motor 40 is coupled to the rotat...

Embodiment 2

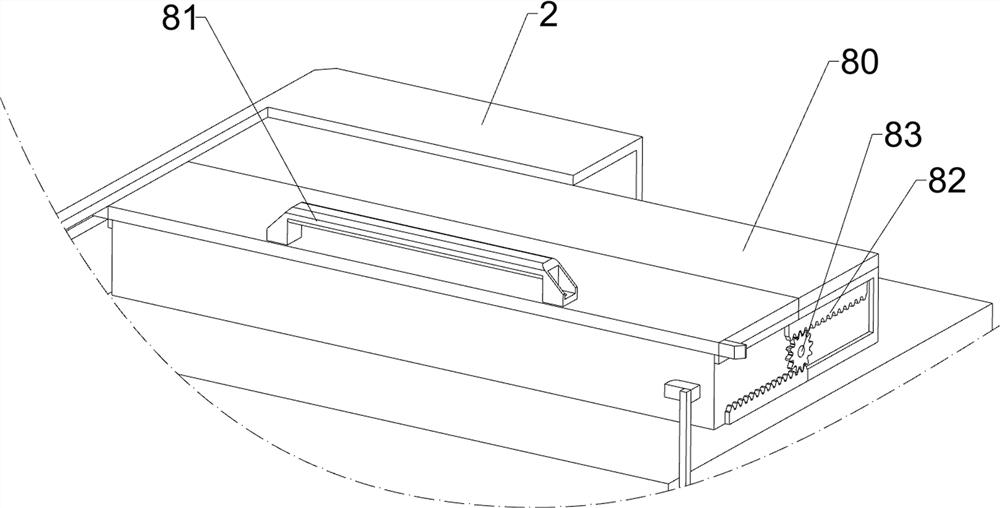

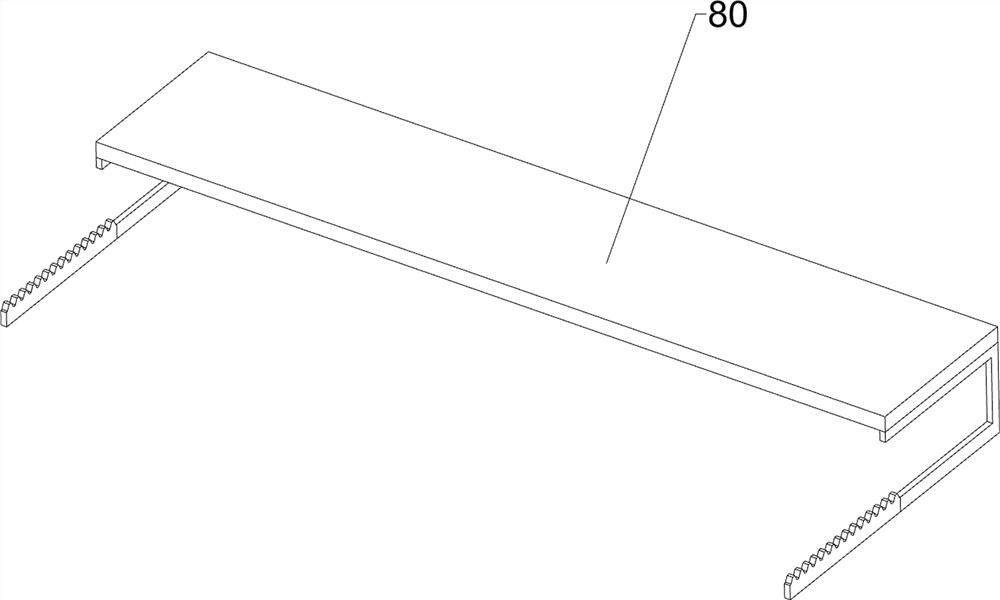

[0044] On the basis of Example 1, such as figure 1 , image 3 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 with Figure 15 The opening and closing assembly 8 is also included, and the opening and closing assembly 8 includes a cover plate 80, a grip 81, a second rack 82, and a second gear 83, and the top and rear symmetry sliding in the top right side of the housing 2 are provided with a cover plate. 80. The front side of the front side of the front side is provided with a grip 81, and the right side of the top right side of the housing 2 is provided with a second gear 83, and the second rack 82 is provided on both sides of the cover plate 80. The second rack 82 is engaged with the second gear 83.

[0045] The user moves toward the front side of the front side by grip 81, drives the upper side of the two second rack 82 to move on the front side, passing two second racks on the upper side. 82 is engaged with the second gear 83, thereby engage the two second rack 82 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com