Measuring instrument for trace moisture in oil

A trace moisture measuring instrument technology, applied in the direction of material inspection products, etc., to achieve the effect of simple operation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further introduced below in combination with specific embodiments.

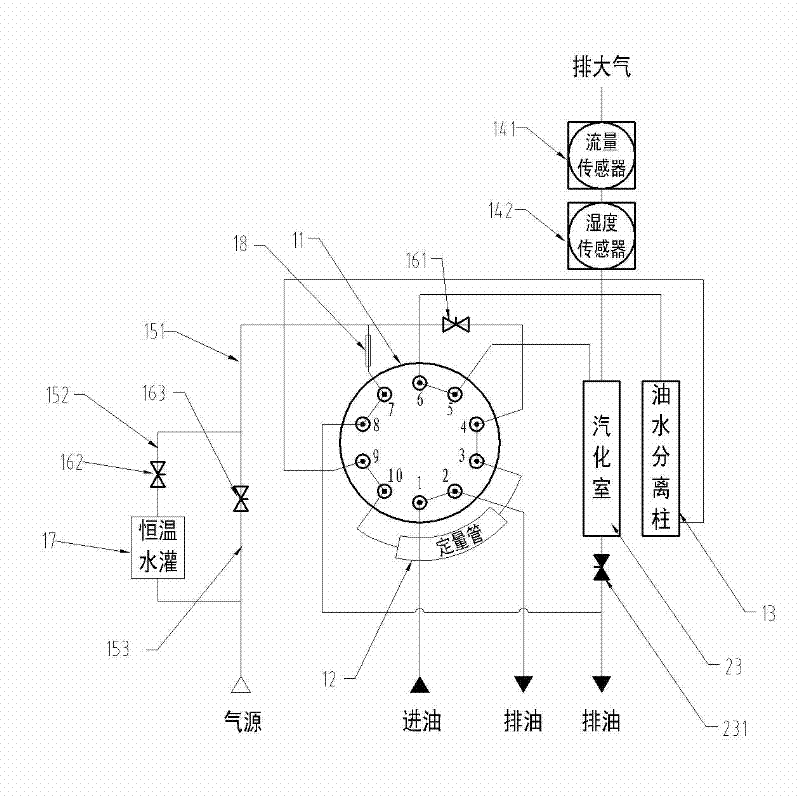

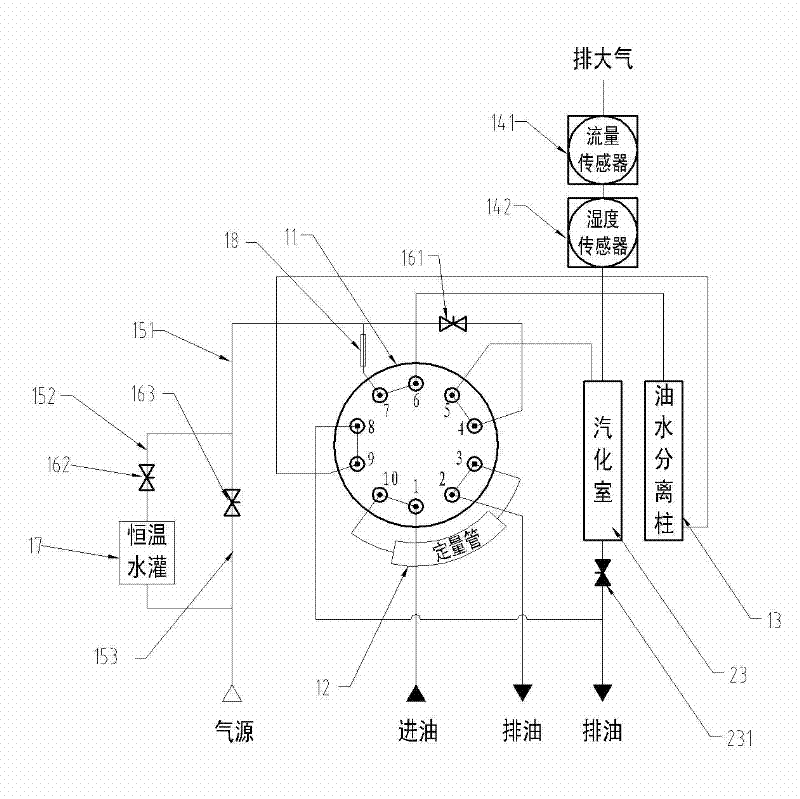

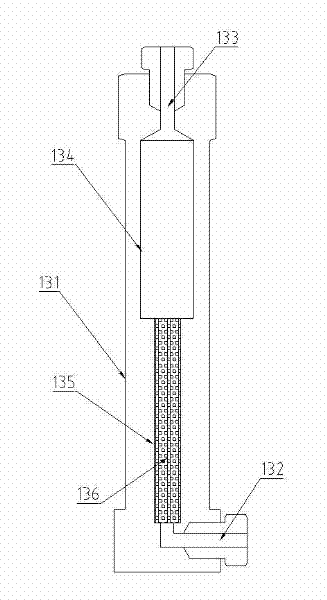

[0036] Such as Figure 1 ~ Figure 2 Shown is the structural schematic diagram of the trace moisture physical measuring instrument in oil. It can be seen from the figure that the device includes a sampling measurement conversion device 11 with the function of switching between sampling and measuring states, and a quantitative measuring device for taking quantitative oil samples to be tested. Pipe 12, oil-water separation column 13 and measurement sensor with inlet and outlet; Measurement sensor includes flow sensor 141 and humidity sensor 142; Gas port 5, overflow port 7 and exhaust port 8, separation outlet 6 and separation inlet 9, quantitative inlet 3 and quantitative outlet 10, quantitative sampling container 12 is connected between quantitative inlet 3 and quantitative outlet 10; The ventilation pipeline before the flow regulating valve in the direction is connected; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com