Automatic separating and recovering device for zinc-nickel permeated layer permeating agent

An automatic separation and recovery device technology, applied in coating, solid-state diffusion coating, metal material coating technology, etc., can solve the problems of labor intensity and dust, increase processing cost, affect the working environment of workers, etc., and achieve full Effect of recovery and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

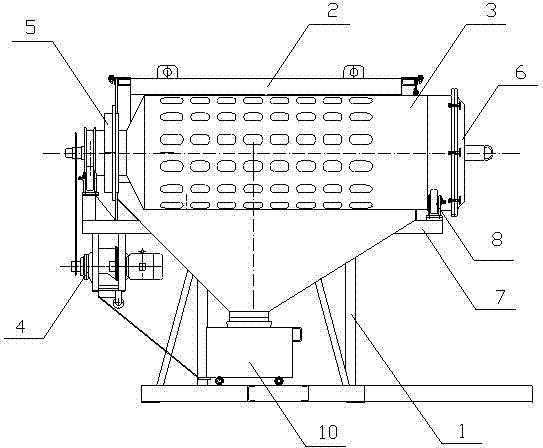

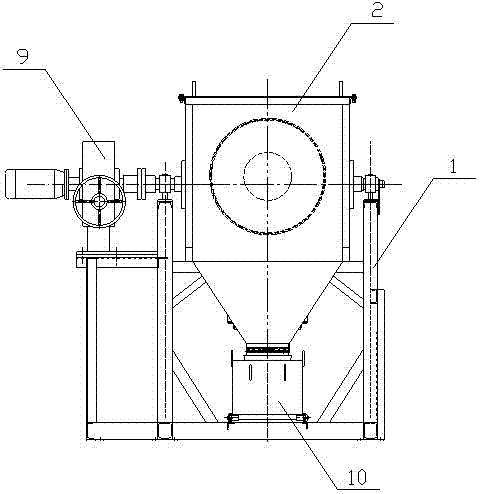

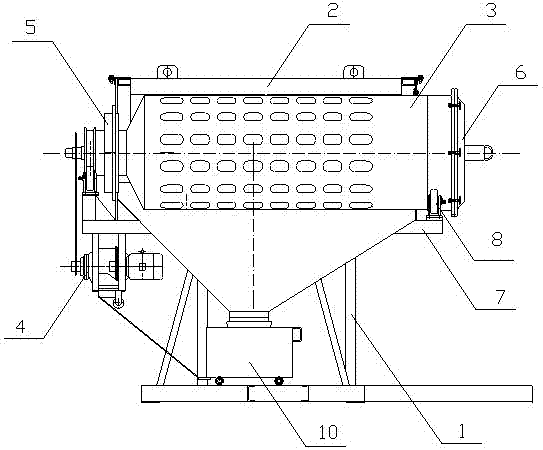

[0016] Example: see figure 1 , figure 2 , the present invention includes an overturning frame 1, an ash box 2, an ash sieve tank 3, an ash sieve tank driving device 4 and an ash receiving trolley 10. The ash box 2 is a box body with two ends open, and its lower side The bottom protrudes, and an ash outlet is opened at the end of the protruding part, and an inserting plate capable of closing the ash outlet is arranged at the ash outlet.

[0017] The ash sieve tank 3 is a tank body with one end closed and the other end open and a side wall with sieve holes. The sealing device 5 seals it with the opening of the ash box 2. Several ribs are fixed on the inner wall of the ash sieve tank 3. The length direction of the ribs is consistent with the axial direction of the ash sieve tank 3. Also be provided with a tank cover 6 that matches it, can open a through hole at the center of tank cover 6 as required, the size of this through hole is consistent with workpiece tooling davit.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com