Cleaning device and method for fragments with grease

A technology for cleaning devices and debris, which is applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc., and can solve the problems of destroying the shape of debris, rising costs, and inapplicability to debris with grease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

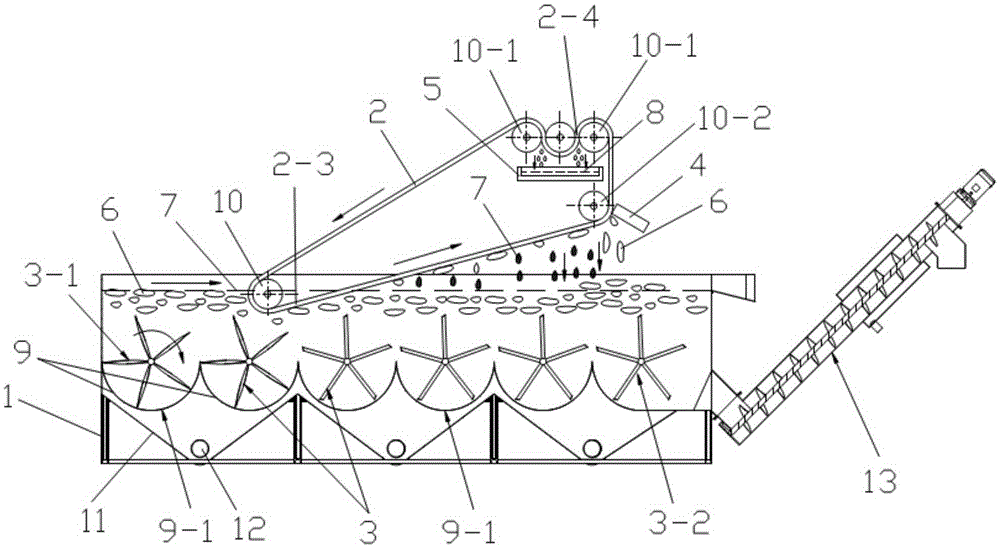

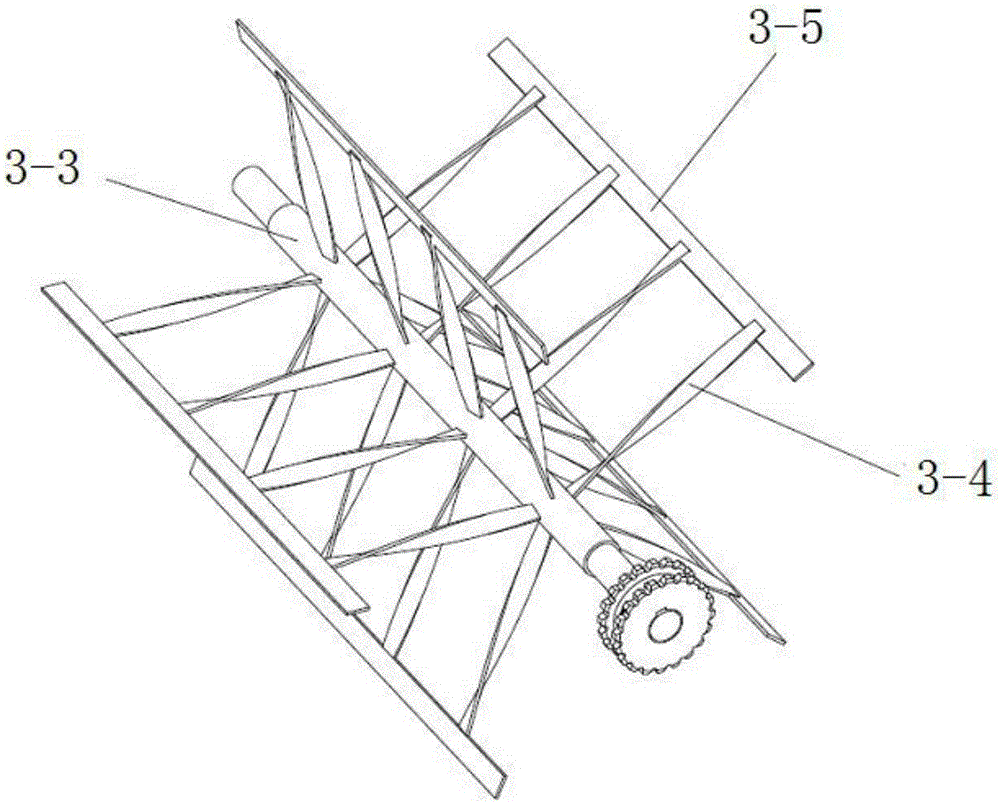

[0046] see figure 1 and figure 2 , the cleaning device with grease fragments of the present embodiment includes a rinsing tank 1, the upper part of the rinsing tank 1 is provided with a grease removal mechanism, and the grease removal mechanism includes a plurality of tension pulleys 10, an oil-absorbing belt wrapped around the tension pulley 10 2. The power mechanism connected with the tension pulley 10, the debris scraper plate 4 and the oil collection tank 5. in:

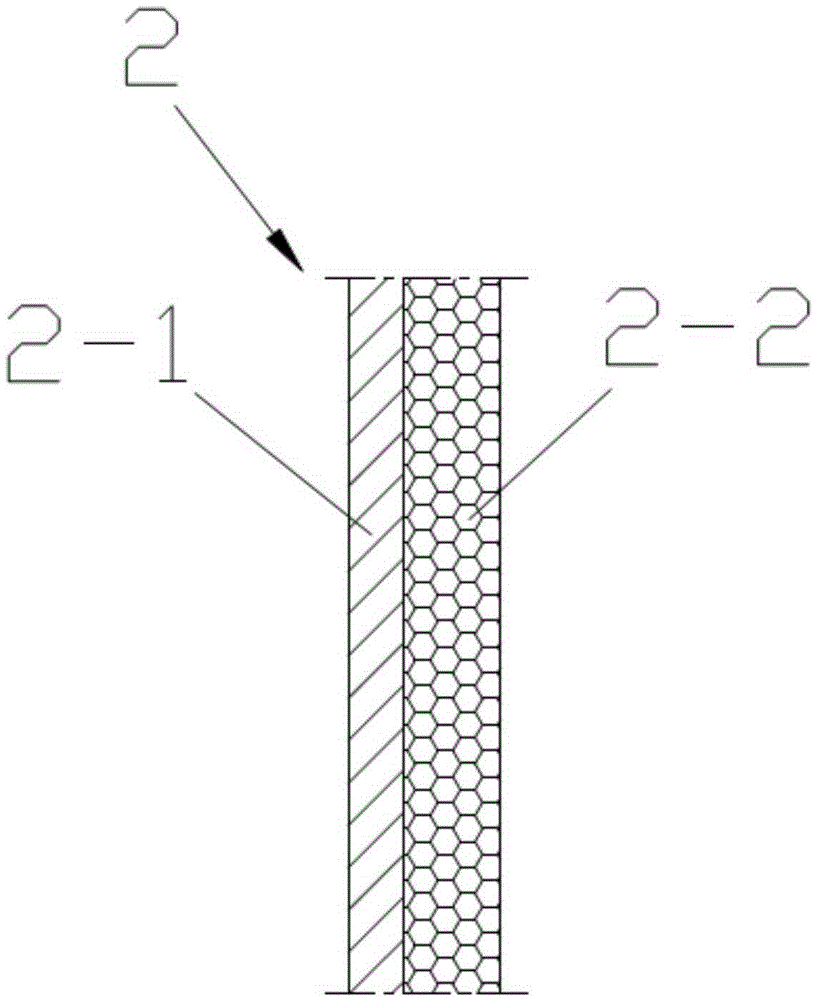

[0047] The oil-absorbing belt 2 is composed of a force-bearing layer 2-1 and an oil-absorbing layer 2-2;

[0048] The plurality of tension pulleys 10 include at least one group of oil squeeze tension pulleys, each group of oil squeeze tension pulleys includes two oil squeeze tension pulleys 10-1, and between the two oil squeeze tension pulleys 10-1 There is an oil squeezing gap smaller than the thickness of the oil-absorbing belt 2, and the oil-absorbing belt 2 passes through the oil-squeezing gap to form an ...

Embodiment 2

[0069] see Figure 6 , the main difference between this embodiment and embodiment 1 is that in this implementation:

[0070] Along the flow direction of the cleaning medium 7, there are two grease removal mechanisms on the rinsing tank 1 . In actual production, according to the oil content of the debris to be cleaned and the oil absorption capacity of a single grease removal mechanism, several grease removal mechanisms are flexibly arranged to ensure that the debris 6 to be cleaned can be fully cleaned.

[0071] In each grease removing mechanism, the position between the oil suction part 2-3 and the oil squeezing part 2-4 of the oil washing belt 2 is vertically arranged.

[0072] In this embodiment, other implementations other than the above are carried out with reference to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com