Automatic conveying and riveting device used for power line plug part with plastic body

A technology for power cords and plastic bodies, applied in lines/collector parts, electrical components, circuits, etc., can solve the problems of potential safety hazards, poor separation of plastic bodies and plug rivets, low work efficiency, etc., to achieve Reduce labor costs, improve production efficiency, and have good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

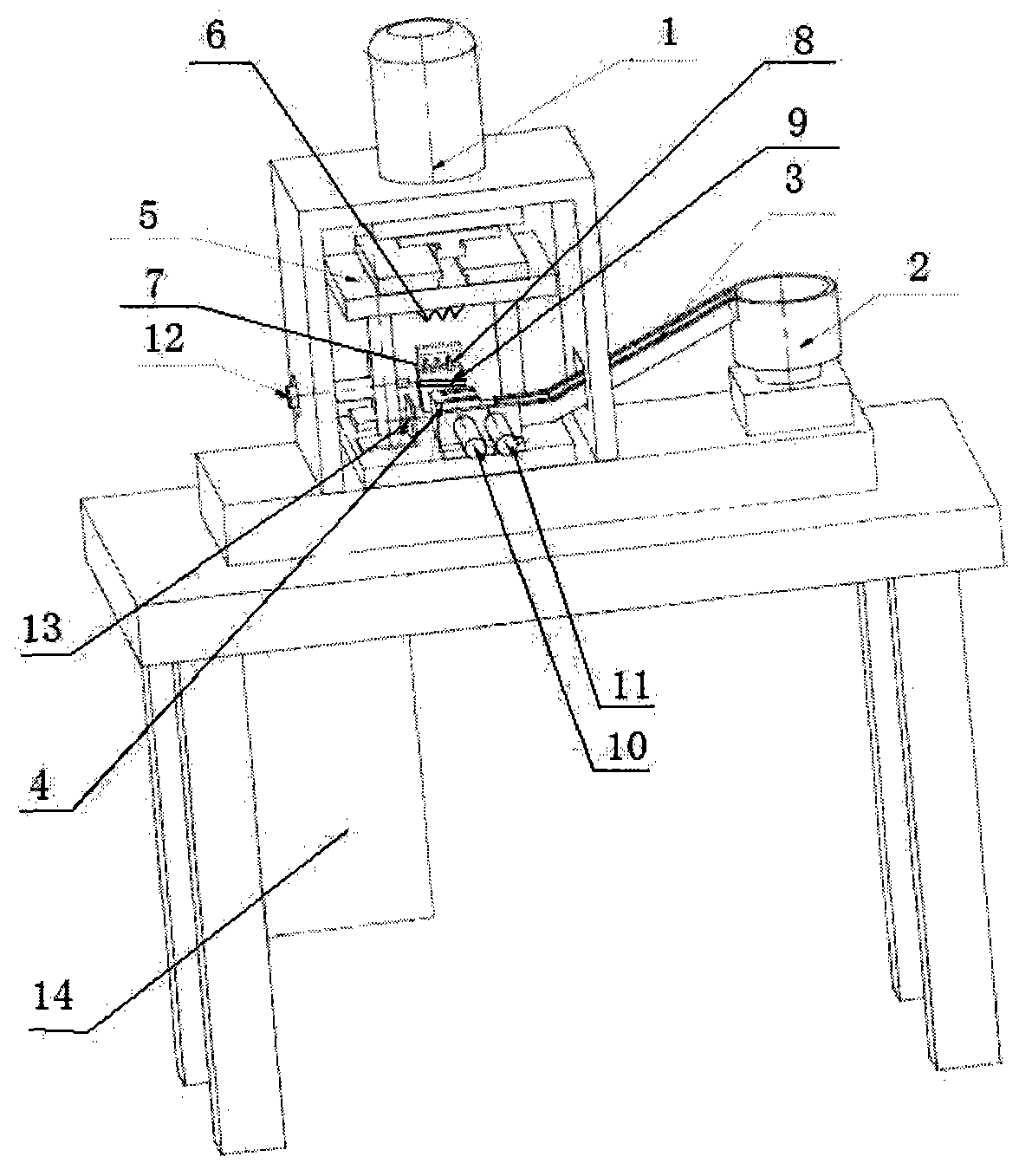

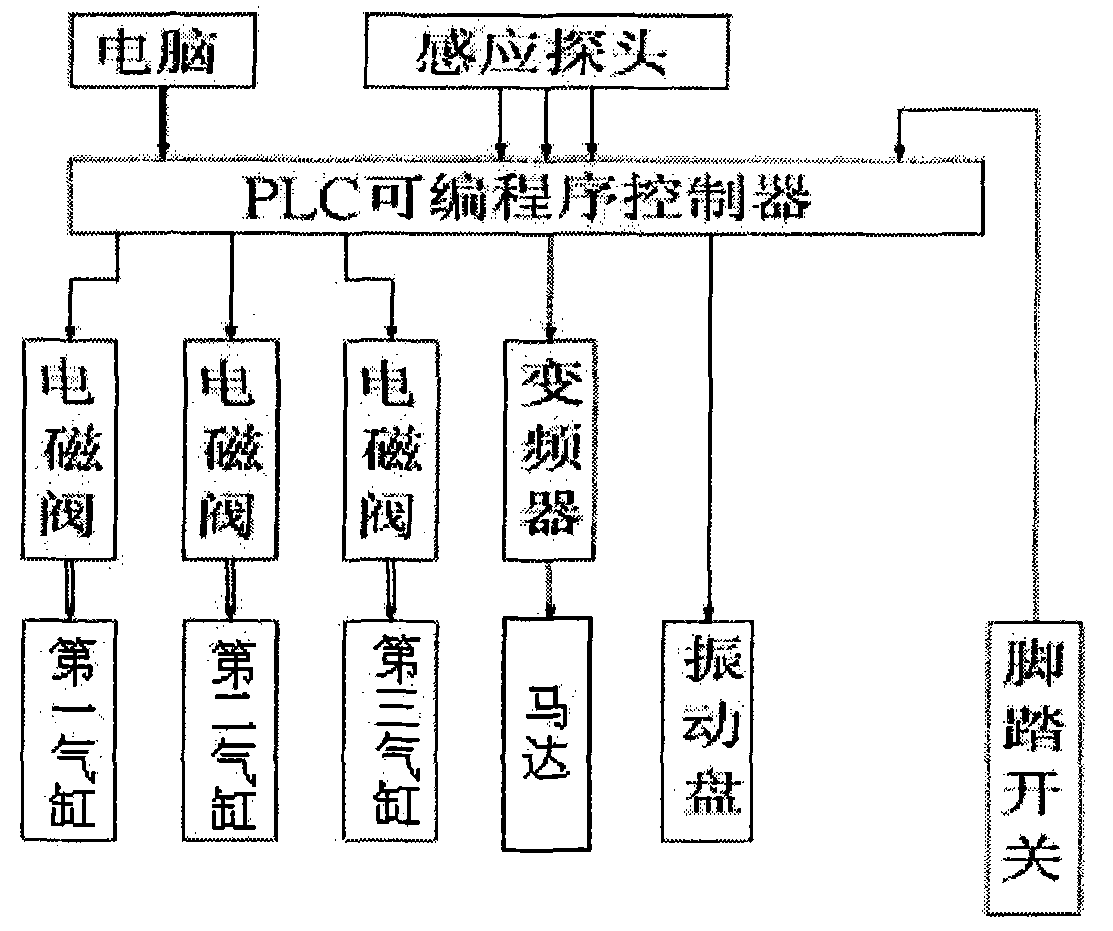

[0020] as attached figure 1 , 2 As shown, the present invention includes a terminal machine 1, a feeding device, a riveting device, an electrical device, an induction probe and a foot switch. The movable feeding base 4 connected to the feeding guide rail 3, the riveting device includes an upper mold base 5, an upper riveting knife mold 6 connected with the upper mold base 5 by screws, a lower mold base 7, and a lower mold base 7 through The screw-connected lower riveting die 8 and the block 9 connected with the lower riveting die 8, the upper die base 5 is connected with the terminal machine 1 through screws, and the electrical device includes a programmable logic controller PLC, which is connected with the The first cylinder 10, the second cylinder 11 and the third cylinder 12 connected by the programmable controller PLC, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com