Device for continuously separating oil-water mixture collected from water surface

A technology of oil-water mixture and pumping device, which is applied in the direction of liquid separation, separation method, liquid separation auxiliary equipment, etc. It can solve the problems that have not been proposed, are rarely seen, and the oil-water separation device is difficult to match, and achieve high stability and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

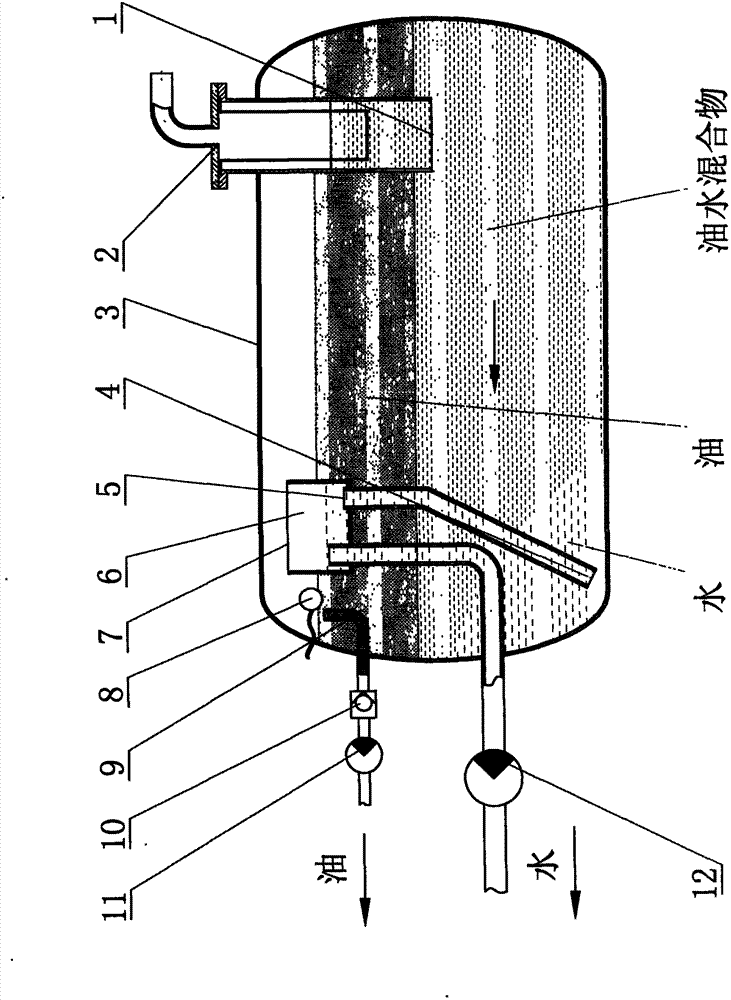

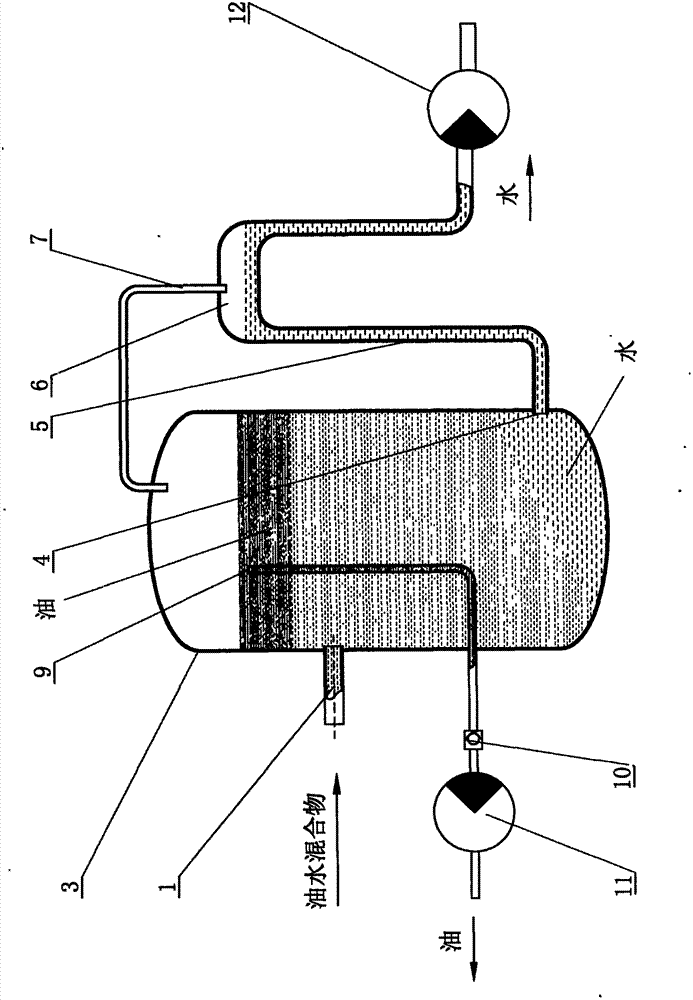

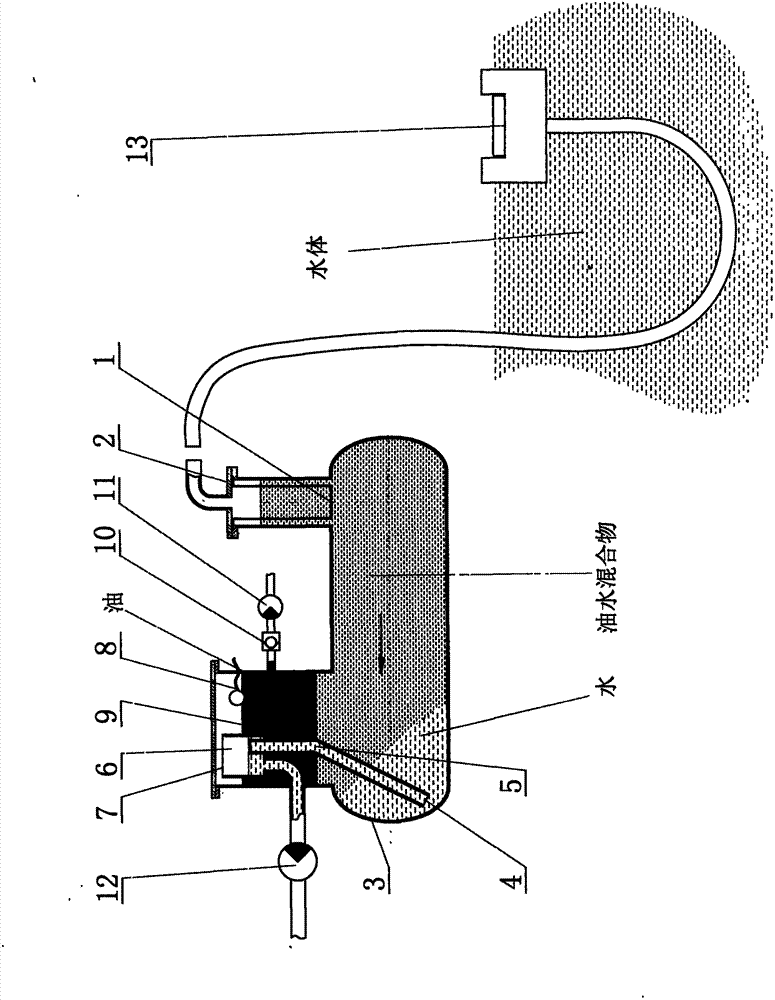

[0045] 1. A device for continuous separation of oil-water mixture collected from water, as attached figure 1 Shown: a vertically placed filter 2 and a horizontally placed tank as a closed container 3; the water outlet end of the filter 2 is used as the oil-water mixture inlet 1 of the closed container, and a water outlet channel 5 is provided at the other end of the closed container 3 to discharge water The channel inlet 4 is located in the lower area of the tank body; the water outlet channel 5 extends from the water outlet channel inlet 4 up to the upper space of the tank body and forms an upper open compartment as the overflow section 6, and the overflow section 6 connects with The upper space of the closed container 3 forms a pressure balance channel 7; the water outlet channel 5 opens in the overflow section 6, passes through the overflow section 6, and then connects with the pumping device 12 (self-priming water pump, water-air mixing pump, diaphragm Pumps, screw pumps, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com