Method for preparing efficient oil-water separation sponge

A technology of oil-water separation and sponge, which is applied in the field of preparation of high-efficiency oil-water separation sponge, to achieve the effect of cheap raw materials, relief of huge pressure, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

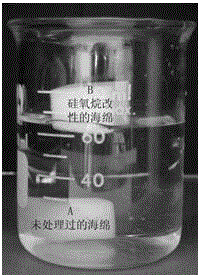

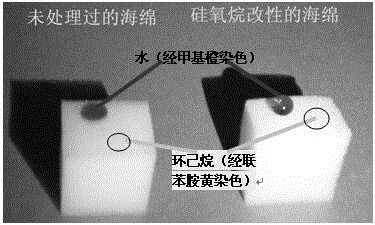

Image

Examples

Embodiment 1

[0018] Mix 15 mL of toluene, chloroplatinic acid-isopropanol solution (1 wt%), 295 μL, and ViD 4 46.78g (136mmol), stir evenly, then add PHMS4.44g (68mmolSi-H), continue to stir evenly, and obtain the immersion liquid. Soak a clean sponge in the immersion liquid, after it is completely soaked, take out and squeeze out the excess immersion liquid, then place it in a drying oven, dry and solidify at 90~100°C to obtain a silicone modified sponge S 2:1 .

Embodiment 2

[0020] Mix 15 mL of toluene, chloroplatinic acid-isopropanol solution (1 wt%), 295 μL, and ViD 4 46.78g (136mmol), stir evenly, then add PHMS2.22g (34mmolSi-H), continue to stir evenly, and obtain the immersion solution. Soak the clean sponge in the immersion liquid, after it is completely soaked, take out and squeeze out the excess immersion liquid, then place it in a drying oven, dry and solidify at 90~100°C, and obtain the silicone modified sponge S 4:1 .

Embodiment 3

[0022] Mix 15 mL of toluene, chloroplatinic acid-isopropanol solution (1 wt%), 295 μL, and ViD 4 46.78g (136mmol), stir evenly, then add PHMS8.88g (136mmolSi-H), continue to stir evenly, and obtain an infusion. Soak the clean sponge in the immersion liquid, after it is completely soaked, take out and squeeze out the excess immersion liquid, then place it in a drying oven, dry and solidify at 90~100°C, and obtain the silicone modified sponge S 1:1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com