Multifunctional automatic tube sorting machine

It is a multi-functional and multifunctional technology, which can be used in containers, packaging, skids, etc. It can solve the problems of increasing operating costs of enterprises, fatigue of production personnel, and low production efficiency, ensuring stability, improving work efficiency, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

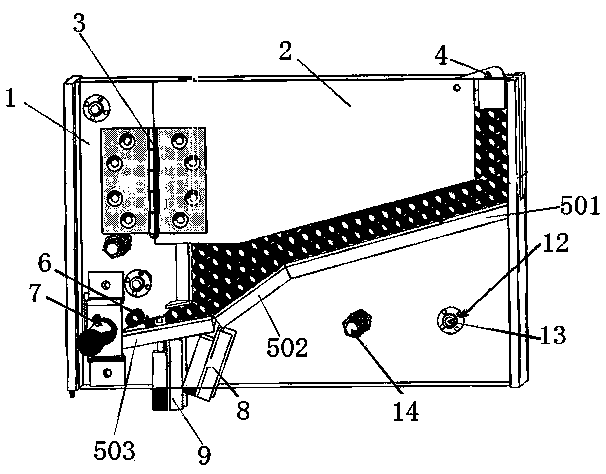

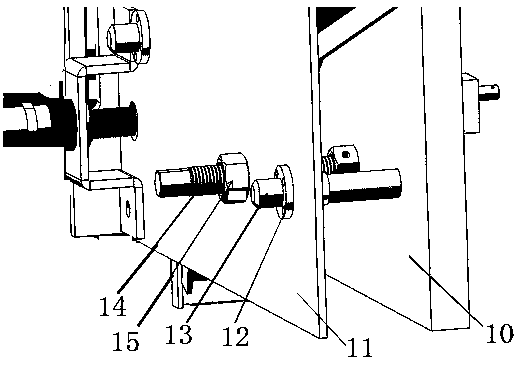

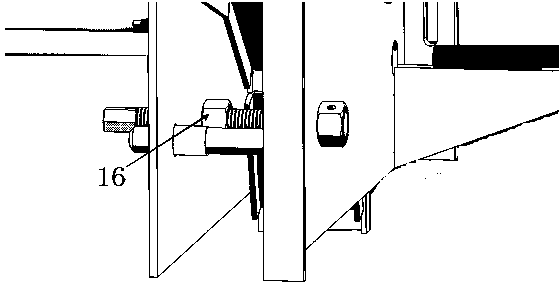

[0018] see figure 1 , A multifunctional automatic pipe splitting machine of the present invention includes a main body 1 , a bin door 2 , a bin door clamping device 4 , a pipe slide, a material retaining device 6 and a pipe moving device 7 .

[0019] Wherein, the door 2 and the main body 1 are preferably pivotally connected with the main body 1 through a hinge 3, so as to facilitate opening the door 2 and putting the pipes into the silo. Such a structure makes it convenient and easy to add pipes to the silo. It can intuitively find the pipes that are not placed in place, realize the convenience, stability and controllability of discharging, save time and improve efficiency. The door clamping device 4 can realize the clamping and release of the door 2, and prevent the door 2 from being accidentally opened during the operation of the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com