Flexible circuit board, flexible LED lamp bar and manufacturing method of flexible LED lamp bar

A flexible circuit board, LED strip light technology, applied in printed circuit parts, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of troublesome alignment, complicated process, many steps, low yield, etc. To achieve the effect of increasing the pulling force, reducing the width and reducing the wrinkle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

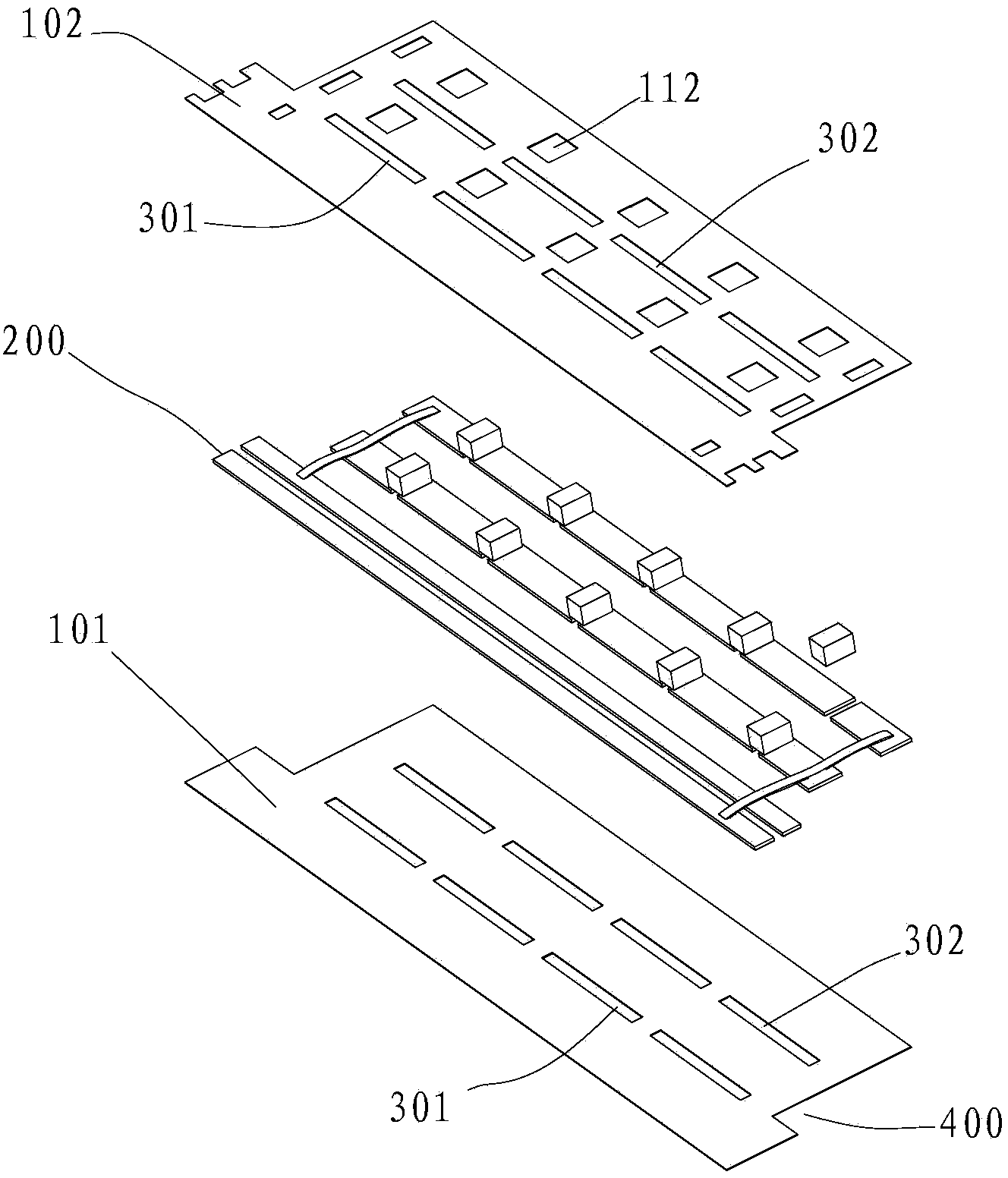

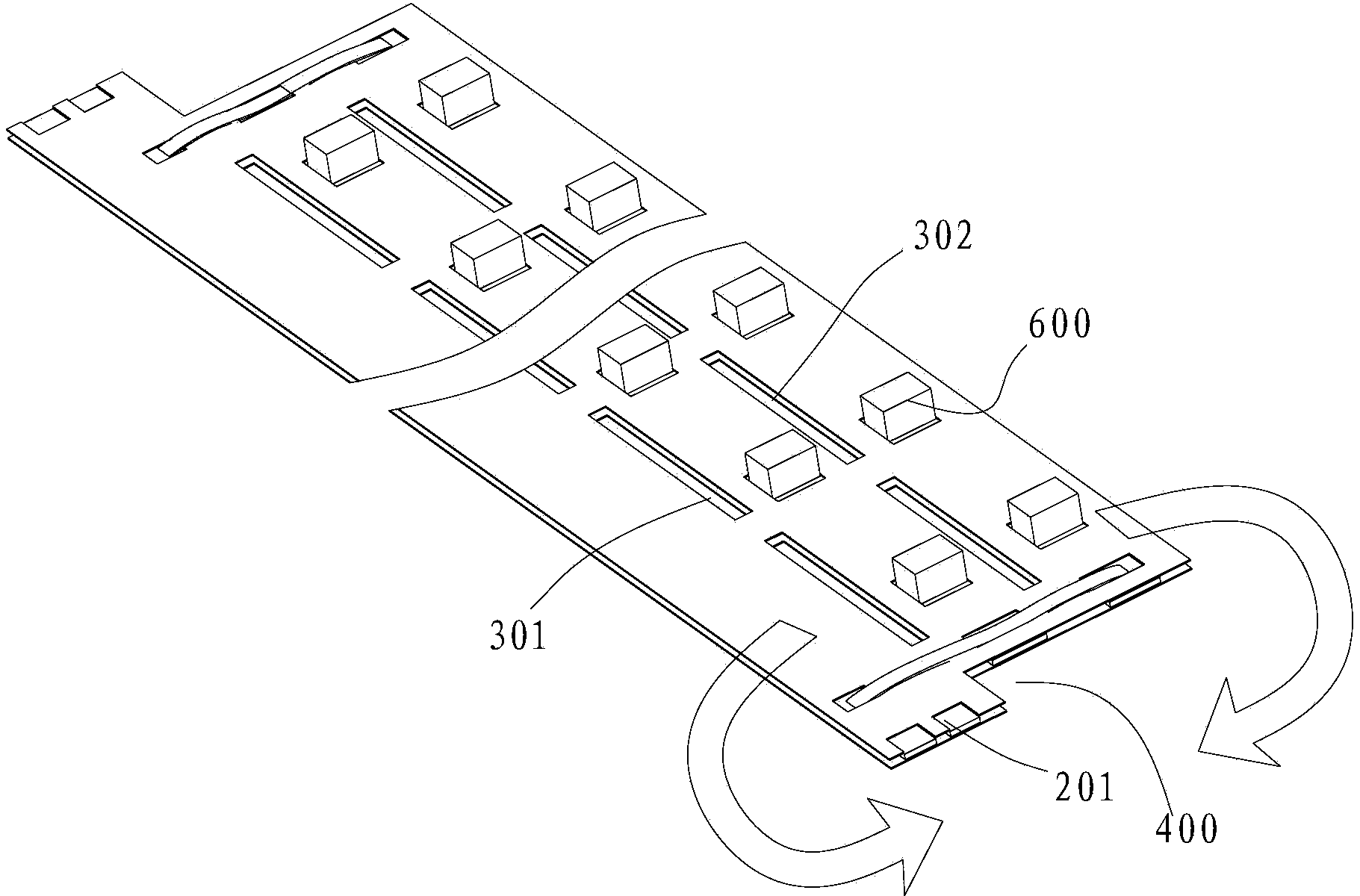

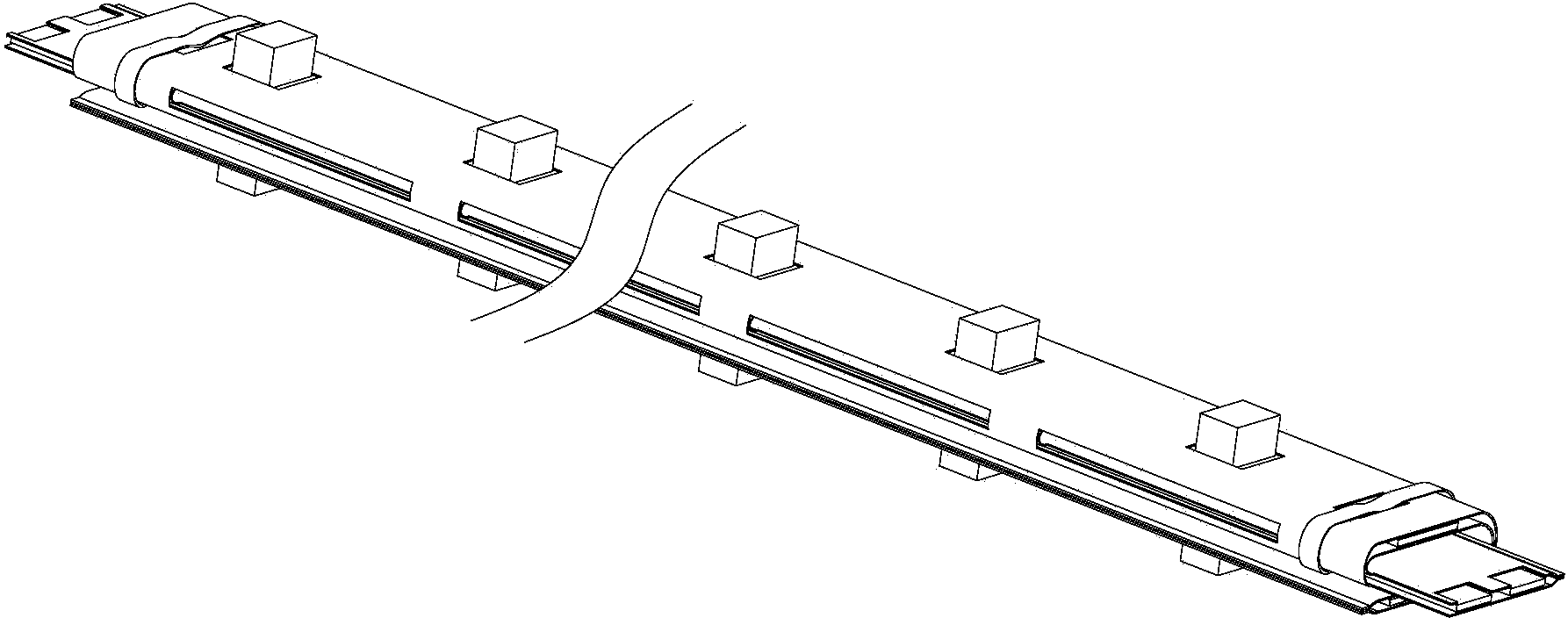

[0084] refer to Figure 1-15As shown, in an embodiment of the present invention, a flexible circuit board includes a first insulating layer 101, a second insulating layer 102, and a circuit layer 200, and the first insulating layer 101 and the second insulating layer 102 are attached to the circuit respectively. On both sides of the layer 200, the lamination can adopt a hot pressing process. The first insulating layer 101 and the second insulating layer 102 are provided with folded parts along the length direction. The folded parts of the first insulating layer 101 and the second insulating layer 102 Corresponding to the position of the folding part, the circuit layer 200 includes a set of power lines 201 and at least one light source line 202. The power line 201 and the light source line 202 are respectively located on both sides of the folding part. In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com