Stack crane and driving control method thereof

A crane and stacking technology, applied in the direction of lifting device, storage device, transportation and packaging, etc., can solve the problems of acceleration limitation, complicated structure and control, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

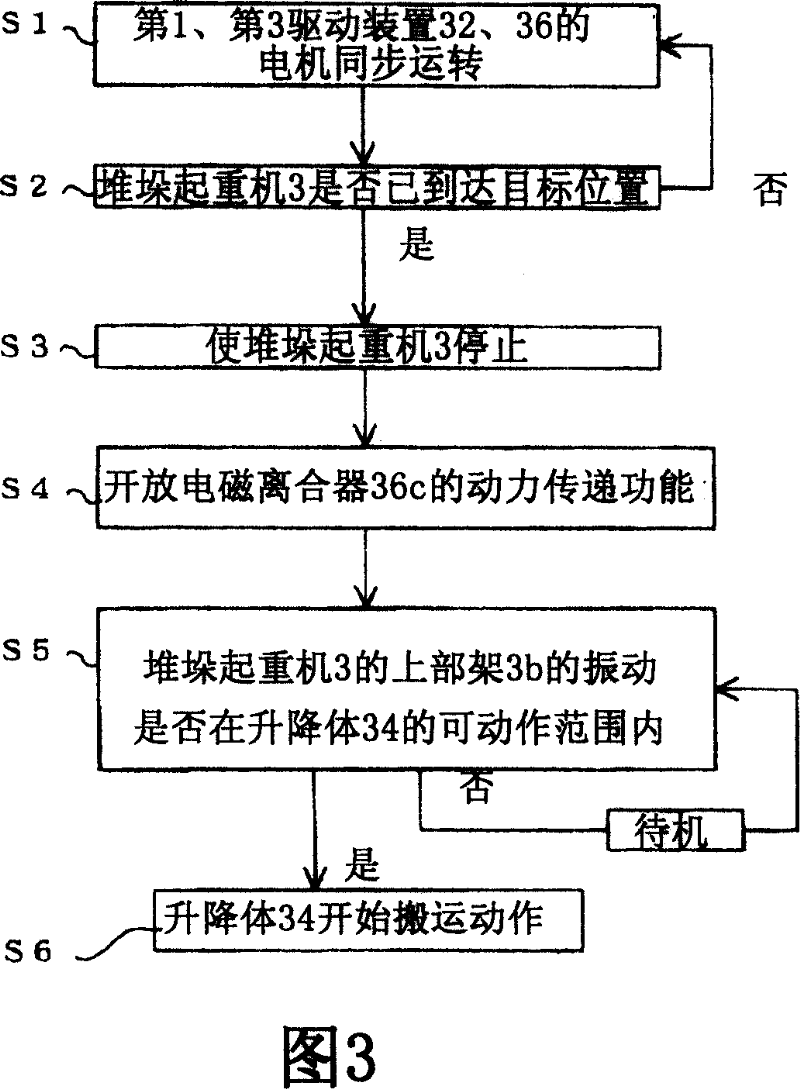

[0038] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

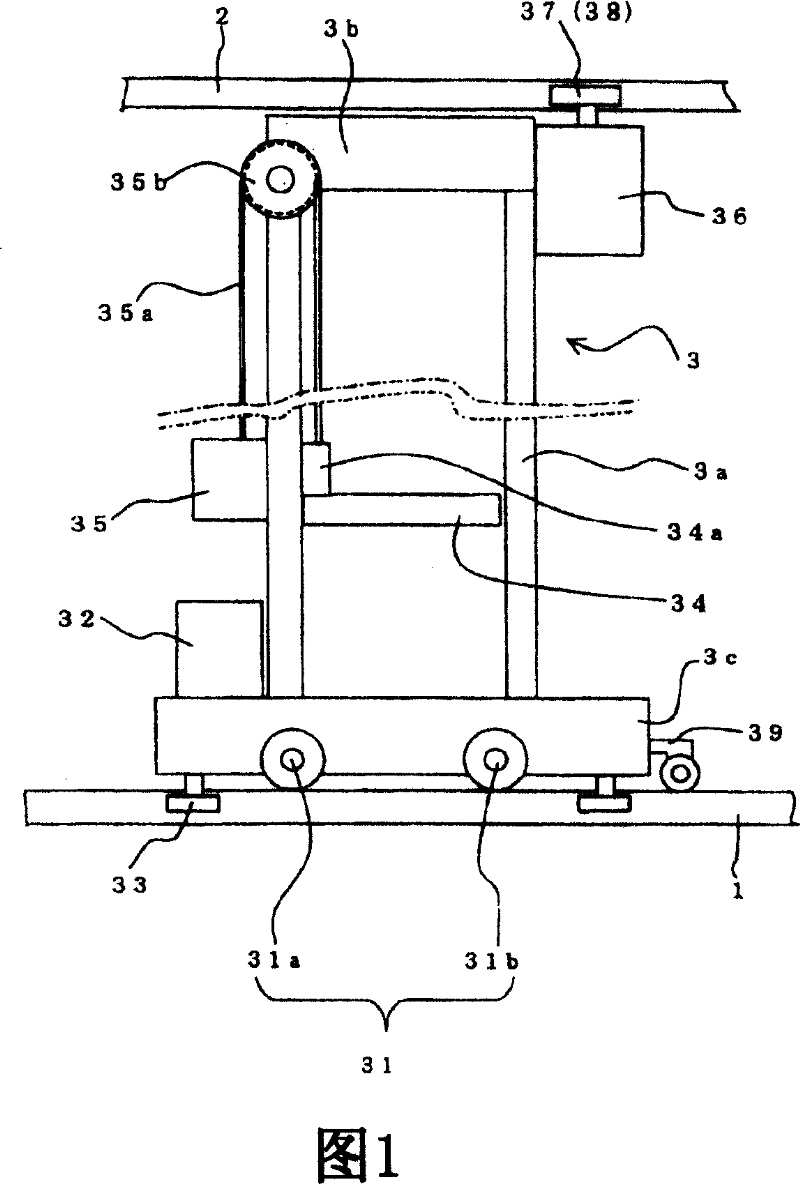

[0039] In Fig. 1, 1 is a guide rail for traveling the stacking crane, and 2 is a guide rail for guiding the upper frame of the stacking crane. They are respectively laid along the prescribed path in the stacker. The stacker is arranged vertically and horizontally to store wafers, etc. Shelves for FOUP storage of substrates. 3 is a stacking crane, the main body of which includes: a column 3a extending in the vertical direction, an upper frame 3b and a lower frame 3c respectively provided at the upper and lower ends of the column 3a.

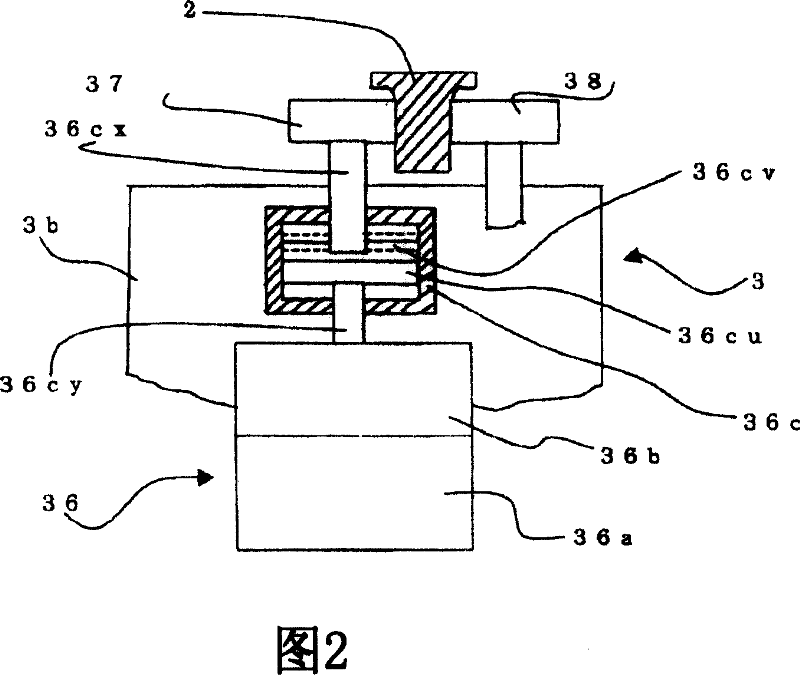

[0040] 31 is a running wheel, which includes a driving wheel 31a and an idler wheel 31b, which are supported by the lower frame 3c and can run on the guide rail 1 for traveling of the stacker crane. 32 is the 1st driving mechanism, has motor, deceleration mechanism and brake, is transmitted power to driving wheel 31a by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com