Double-sided monocrystalline laminated photovoltaic module and manufacturing method thereof

A photovoltaic module and manufacturing method technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of increasing glass area, power difference, product backlog, etc., and achieve the goal of saving module area, improving module efficiency, and reducing glass length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

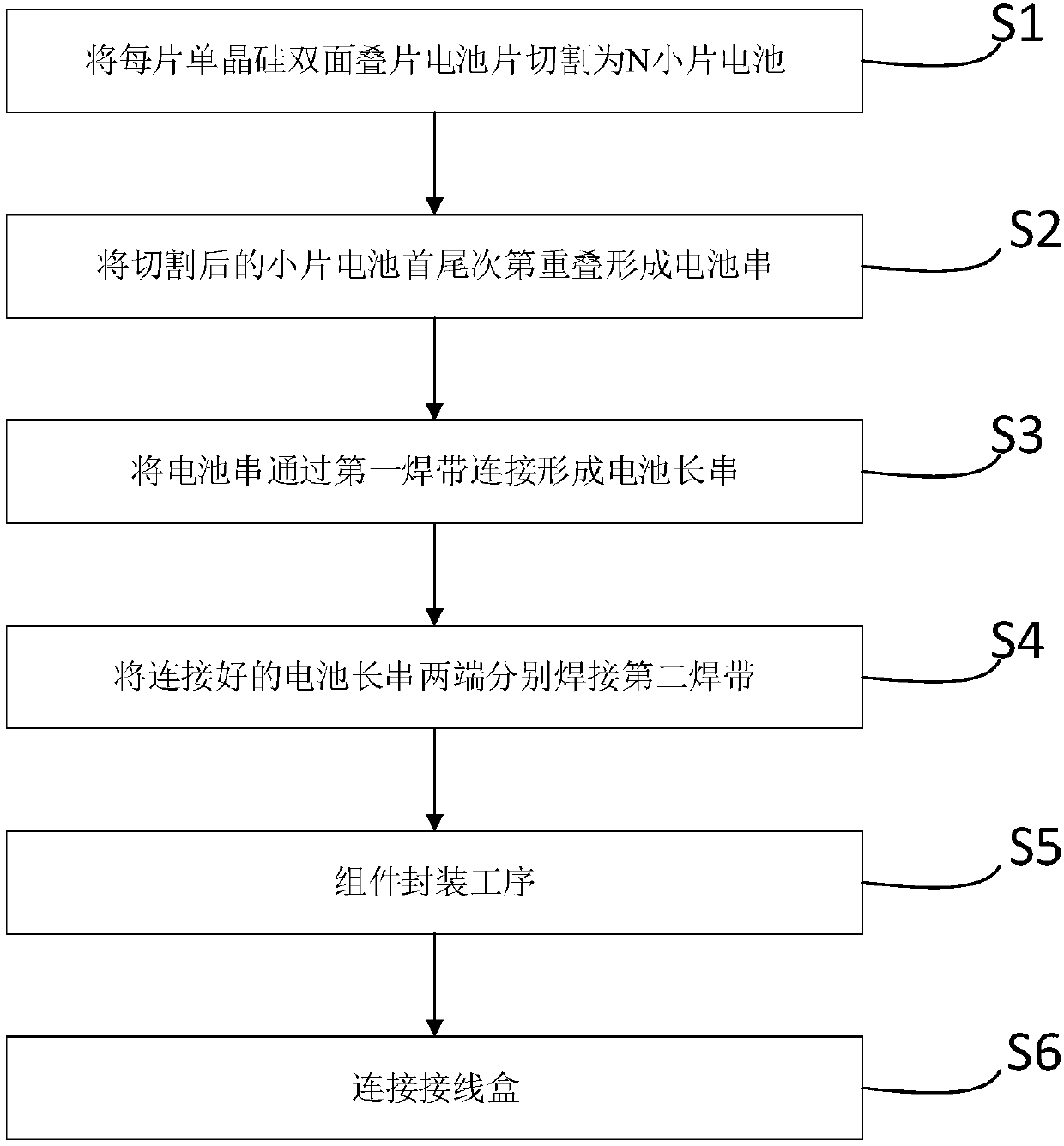

[0045] Such as figure 1 As shown, a method for manufacturing a double-sided single crystal laminated photovoltaic module of the present invention comprises the following steps:

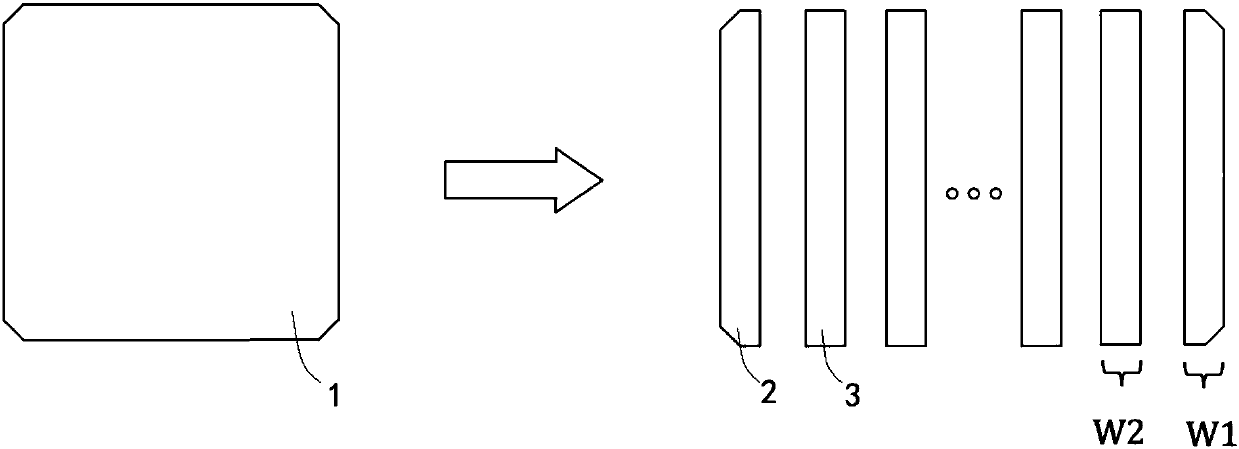

[0046] S1, cutting each monocrystalline silicon double-sided laminated cell 1 into N small cells;

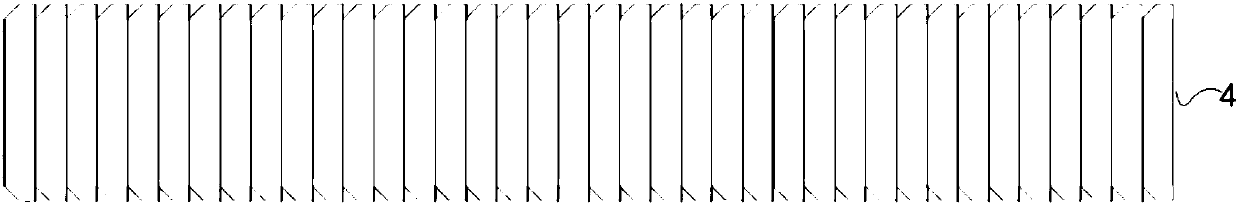

[0047] S2, overlapping the cut small pieces of batteries end to end to form a battery string;

[0048] S3, connecting the battery strings through the first welding ribbon to form a long battery string;

[0049] S4, respectively welding the two ends of the connected battery string to the second welding strip;

[0050] S5, component packaging process;

[0051] S6, connect the junction box.

[0052] Such as Figure 2-Figure 9 Specific steps are as follows:

[0053] Such as figure 2 As shown, each monocrystalline silicon double-sided laminated cell 1 is cut into N small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com