Exposure unit

A technology of exposure device and exposure surface, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, optics, etc., can solve problems such as easy accumulation of dust and poor exposure, and improve image resolution, high quality and productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

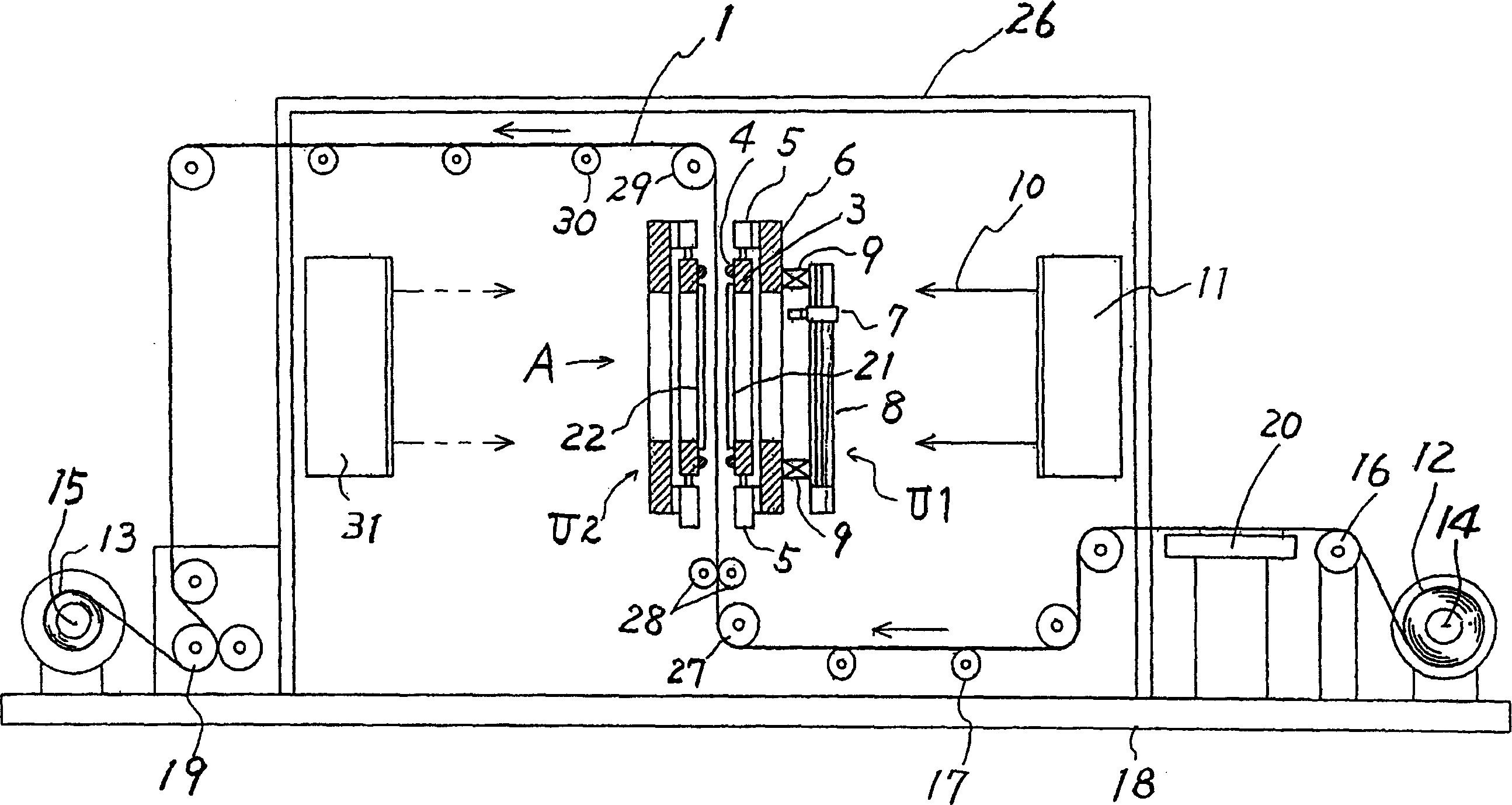

[0027] figure 1 It is a schematic vertical cross-sectional view showing an example of the exposure apparatus of the present invention. The exposure device includes: a base 18 and a frame 26 disposed on the base 18 . On the right end portion of the base 18, the reel 14 for drawing out is provided. The flexible tape-shaped substrate 1 is wound into a cylinder 12 on the reel 14 for extraction. On the other hand, a winding reel 15 is provided at the left end portion of the base 18 .

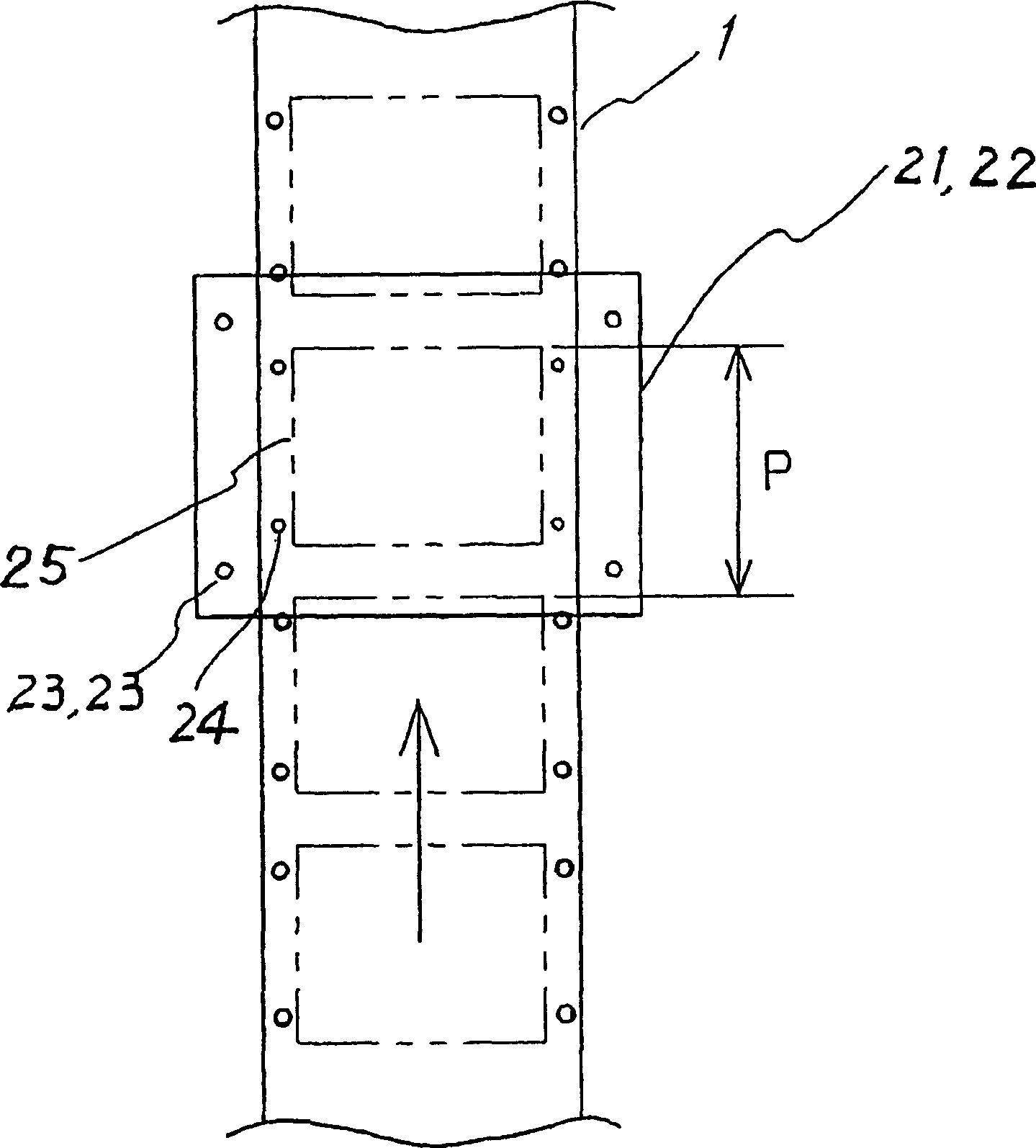

[0028] A conveying drive roller 19 is provided between the unwinding reel 14 and the winding reel 15 . The conveyance drive roller 19 intermittently draws out the strip-shaped substrate 1 wound on the take-out reel 14 every predetermined length. The strip-shaped substrate 1 drawn out from the drawing reel 14 enters a vertical path through guide rollers 16, 17, 27, 28, and becomes a vertical state. The region where the strip substrate 1 is in a vertical state is an exposed portion. In the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com