Production method of high-performance titanium alloy blind pipe

A manufacturing method, titanium alloy technology, which is applied in the field of rapid manufacturing of metal slender blind pipes, can solve problems such as unstable quality, long production cycle, and low material utilization rate, achieve stable material performance and internal quality, and increase yield , the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The specific manufacturing steps of a kind of TC4 titanium alloy blind pipe manufacturing method of the present invention are as follows:

[0029] (a) A graphite-based coating is coated on the surface of the mandrel 2 as a solder resist layer, and the thickness δ of the graphite-based coating is 4mm.

[0030] The mandrel 2 is made of low carbon steel or stainless steel, the mandrel 2 is cylindrical and the front end is a conical head. The diameter of the mandrel 2 is d=D-2δ, wherein D is the inner diameter of the titanium alloy dead leg, and δ is the thickness of the graphite coating on the mandrel 2 .

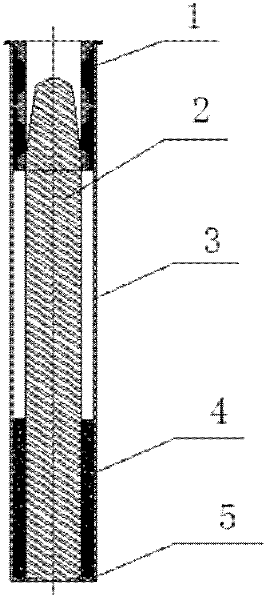

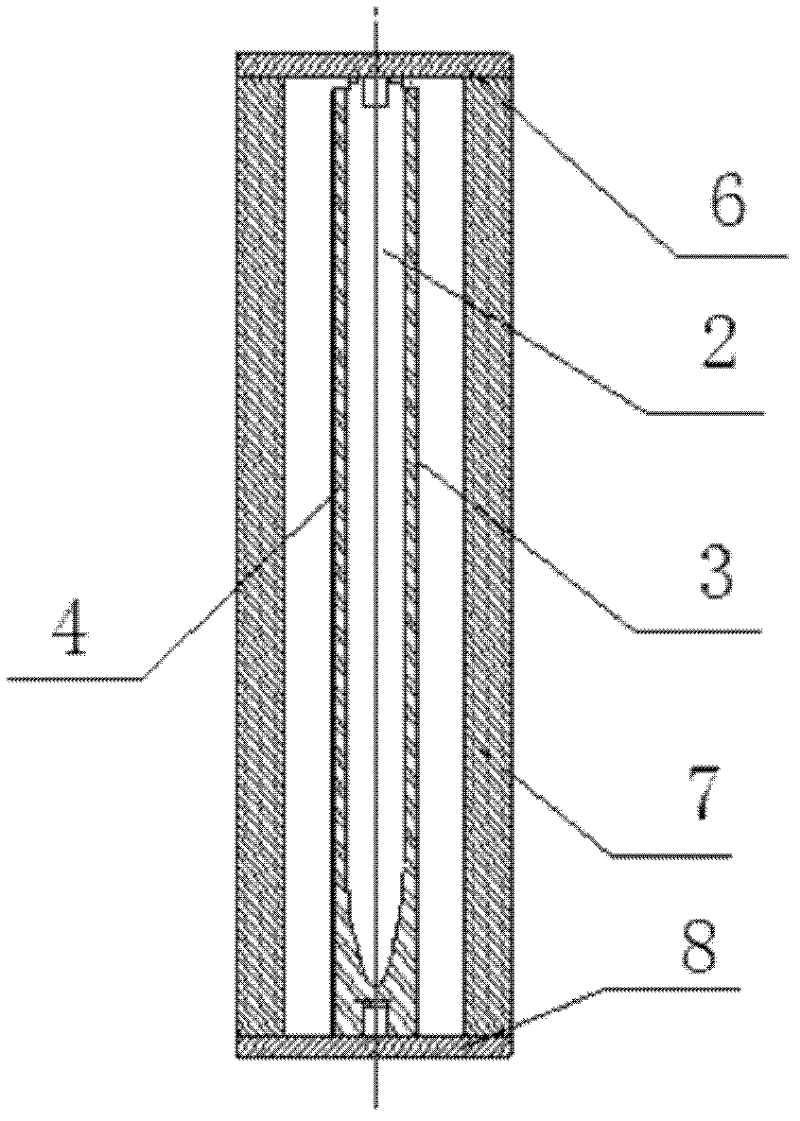

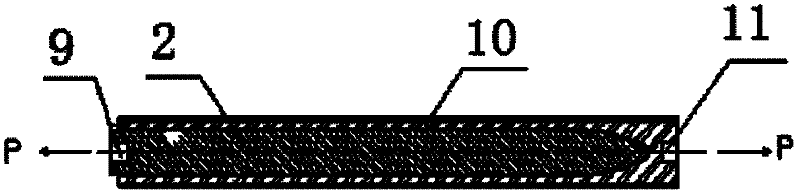

[0031] (b) if figure 1 As shown, the mandrel 2 is placed in the bag sleeve 3, the mandrel 2 is stuck in the center of the bag sleeve 3 through the mandrel positioning tool 1, and the bottom end of the mandrel 2 is fixed on the bottom cover 5 of the bag. Cover bottom cover 5 is welded on bag sleeve 3 bottoms. The mandrel positioning tool 1 is a cylinder that can be pl...

Embodiment 2

[0040] The specific manufacturing steps of a kind of TC4 titanium alloy blind pipe manufacturing method of the present invention are as follows:

[0041] (a) A graphite-based coating is coated on the surface of the mandrel 2 as a solder resist layer, and the thickness δ of the graphite-based coating is 2mm.

[0042]The mandrel 2 is made of low carbon steel or stainless steel, the mandrel 2 is cylindrical and the front end is a conical head. The diameter of the mandrel 2 is d=D-2δ, wherein D is the inner diameter of the titanium alloy dead leg, and δ is the thickness of the graphite coating on the mandrel 2 .

[0043] (b) if figure 1 As shown, the mandrel 2 is placed in the bag sleeve 3, the mandrel 2 is stuck in the center of the bag sleeve 3 through the mandrel positioning tool 1, and the bottom end of the mandrel 2 is fixed on the bottom cover 5 of the bag. Cover bottom cover 5 is welded on bag sleeve 3 bottoms. The mandrel positioning tool 1 is a cylinder that can be pla...

Embodiment 3

[0051] The specific manufacturing steps of a kind of TC4 titanium alloy blind pipe manufacturing method of the present invention are as follows:

[0052] (a) A graphite-based coating is coated on the surface of the mandrel 2 as a solder resist layer, and the thickness δ of the graphite-based coating is 10 mm.

[0053] The mandrel 2 is made of low carbon steel or stainless steel, the mandrel 2 is cylindrical and the front end is a conical head. The diameter of the mandrel 2 is d=D-2δ, wherein D is the inner diameter of the titanium alloy dead leg, and δ is the thickness of the graphite coating on the mandrel 2 .

[0054] (b) if figure 1 As shown, the mandrel 2 is placed in the bag sleeve 3, the mandrel 2 is stuck in the center of the bag sleeve 3 through the mandrel positioning tool 1, and the bottom end of the mandrel 2 is fixed on the bottom cover 5 of the bag. Cover bottom cover 5 is welded on bag sleeve 3 bottoms. The mandrel positioning tool 1 is a cylinder that can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com