Solar battery cell and process for producing the same

一种太阳能电池、制造方法的技术,应用在电气元件、最终产品制造、可持续制造/加工等方向,能够解决工序数增加、无法高效地量产太阳能电池单元等问题,达到制造工序简化、电池单元特性优良、廉价制作的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

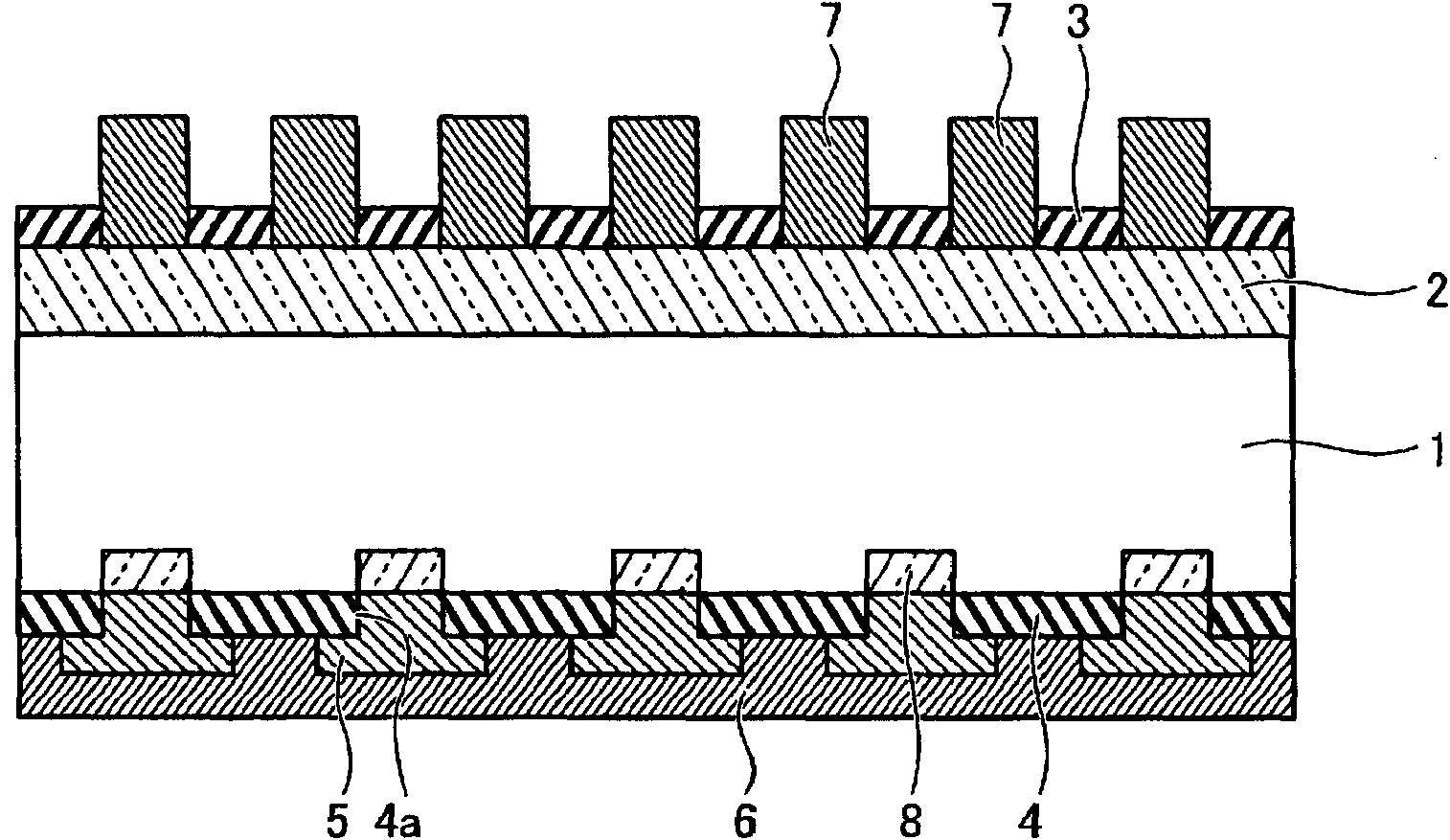

[0061] figure 1 It is a cross-sectional view for explaining the structure of the solar cell according to Embodiment 1 of the present invention. In the solar cell of this embodiment, on the light-receiving surface side of the semiconductor substrate 1 made of p-type silicon, the impurity diffusion layer (n-type impurity diffusion layer) 2 is formed by diffusion of phosphorus, and the silicon nitride film is formed. The antireflection film 3 constituted.

[0062] As the semiconductor substrate 1, a p-type single crystal or polycrystalline silicon substrate can be used. In addition, the substrate is not limited thereto, and an n-type silicon substrate may also be used. In addition, a silicon oxide film may also be used for the antireflection film 3 . In addition, on the light-receiving surface side surface of the semiconductor substrate 1 of the solar battery cell, fine unevenness is formed as a texture structure. The micro-concave-convex is a structure that increases the are...

Embodiment approach 2

[0081] In Embodiment 2, another solar battery cell and its manufacturing method of the present invention will be described in detail. Figure 4 It is a sectional view for explaining the structure of the solar cell of Embodiment 2 of this invention. In addition, in the following drawings, with respect to the same structure as Embodiment 1, by adding and figure 1 The same symbols are used, and detailed explanations are omitted.

[0082] In the solar cell of this embodiment, on the light-receiving surface side of the semiconductor substrate 1 made of p-type silicon, an impurity diffusion layer (n-type impurity diffusion layer) 2 is formed by diffusion of phosphorus and a silicon nitride film is formed. anti-reflection film 3. On the light-receiving surface side surface of the semiconductor substrate 1 of the solar battery cell, fine unevenness is formed as a texture structure. The micro-concave-convex is a structure that increases the area that absorbs light from the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com