Tool for pressing small copper sleeve of engine connecting rod

A technology of engine connecting rods and press-fitting tools, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., and can solve the problem that the positioning device cannot be completely fixed, the position of the copper sleeve press-fitting is difficult to grasp, and it is easy to fall into the press Problems in the machine tool to achieve the effect of preventing the deformation of the copper sleeve, convenient operation, and reducing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

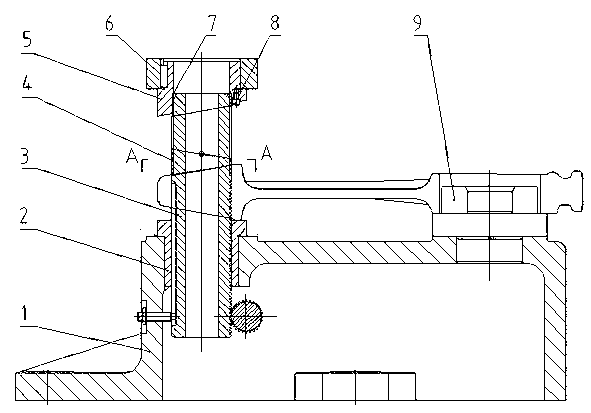

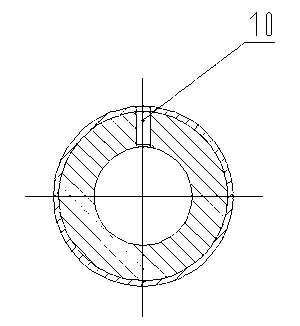

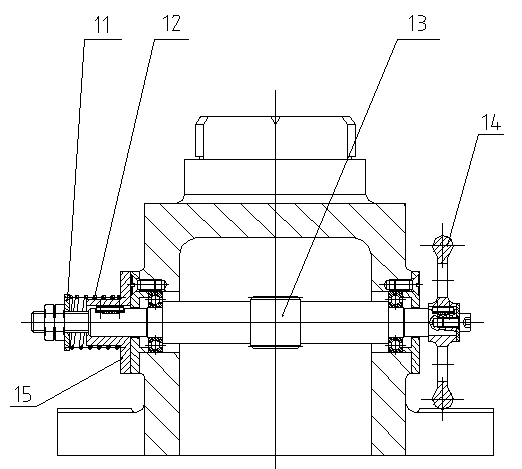

[0021] Pressing tools for the copper sleeve of the small end of the engine connecting rod, such as Figure 1-3 As shown, it is mainly composed of base 1, guide post 3, pressure sleeve 5, diamond-shaped positioning pin 9, gear shaft 13, and hand wheel 14.

[0022] like figure 1 As shown, the base 1 is fixed on the press, and the upper end surface of the base 1 is processed with two light holes. The light hole on the left side of the base 1 is fitted with the shaft sleeve 2 that matches the light hole, and the guide post 3 is placed in the shaft sleeve 2 . The guide post 3 is a stepped shaft that is thick at the bottom and thin at the top. The diameter of the bottom of the stepped shaft corresponds to the aperture of the small end of the connecting rod, and the diameter of the top of the stepped shaft is smaller than the aperture of the small end of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com