Rear axle lining press-fitting machine

A press-fitting machine and bushing technology, which is applied in the field of press-fitting machines, can solve the problems of difficulty in putting in and taking out the rear axle assembly, and achieve the effect of convenient press-fitting and high-precision press-fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

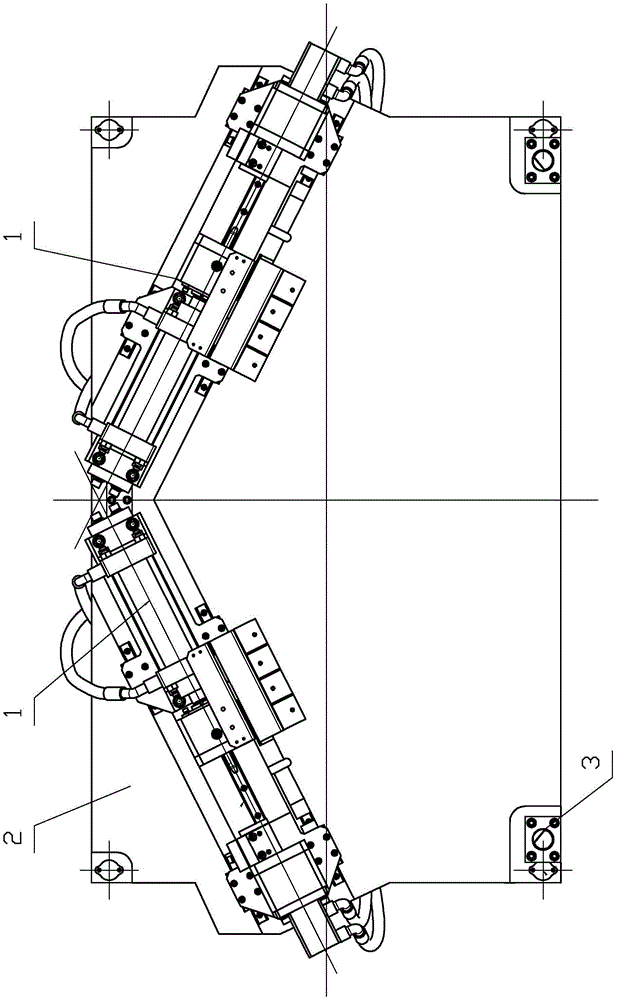

[0035] A rear axle bushing press-fitting machine, comprising two symmetrically arranged press-fit devices 1, the two sets of press-fit devices 1 are symmetrically installed on a workbench 2, and a workpiece positioning mechanism 3 is arranged on the workbench 2, and the workpiece positioning mechanism 3 is Known technology, its structure is not described in detail here.

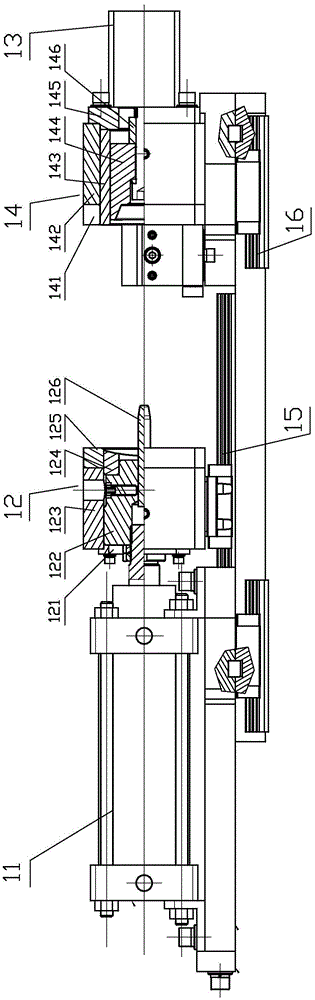

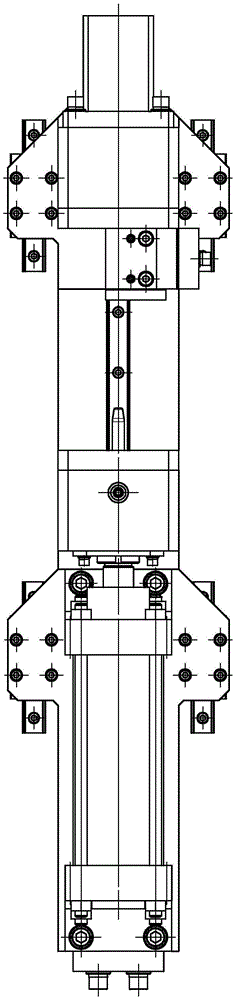

[0036] Each set of pressing device 1 includes a main hydraulic cylinder 11, a main pressure head 12, an auxiliary hydraulic cylinder 13, an auxiliary pressure head 14, a main guide rail 15, and an auxiliary guide rail 16. The main hydraulic cylinder 11 is a standard hydraulic cylinder. The extended end of the cylinder 11 is connected with the main pressure head 12, the bottom of the main pressure head 12 is slidingly fitted with the main rail 15, and the main pressure head 12 is connected with the bushing; the auxiliary hydraulic cylinder 13 is a thin hydraulic cylinder, and the auxiliary hydraulic cylinder T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com