Combined pressing device for online assembly of forklift gearbox

A technology of a pressing device and a gearbox, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of small working space, low pressing precision, roller table damage, etc., so as to improve work efficiency and pressing precision. The effect of high and good operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

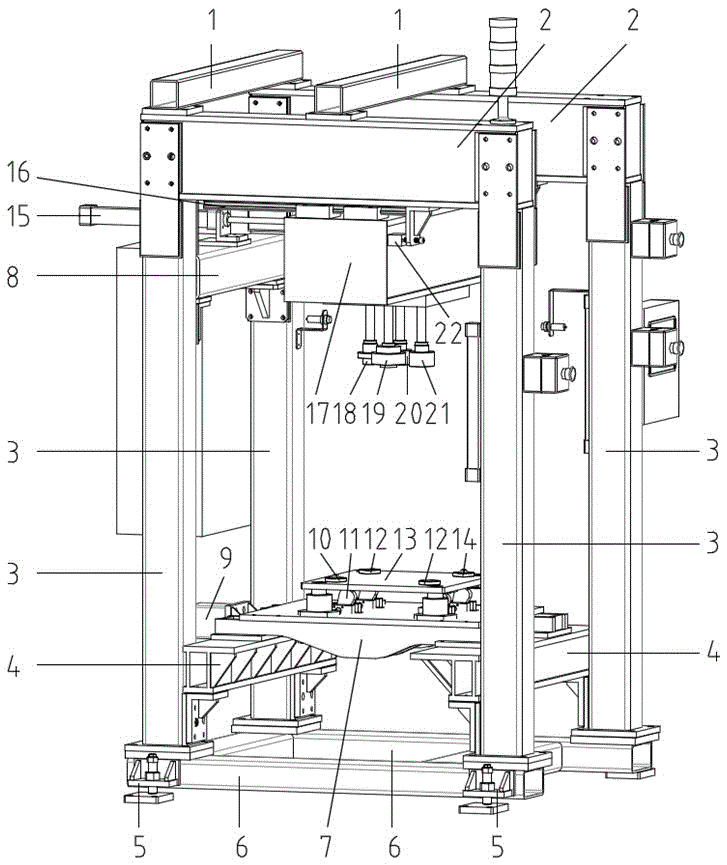

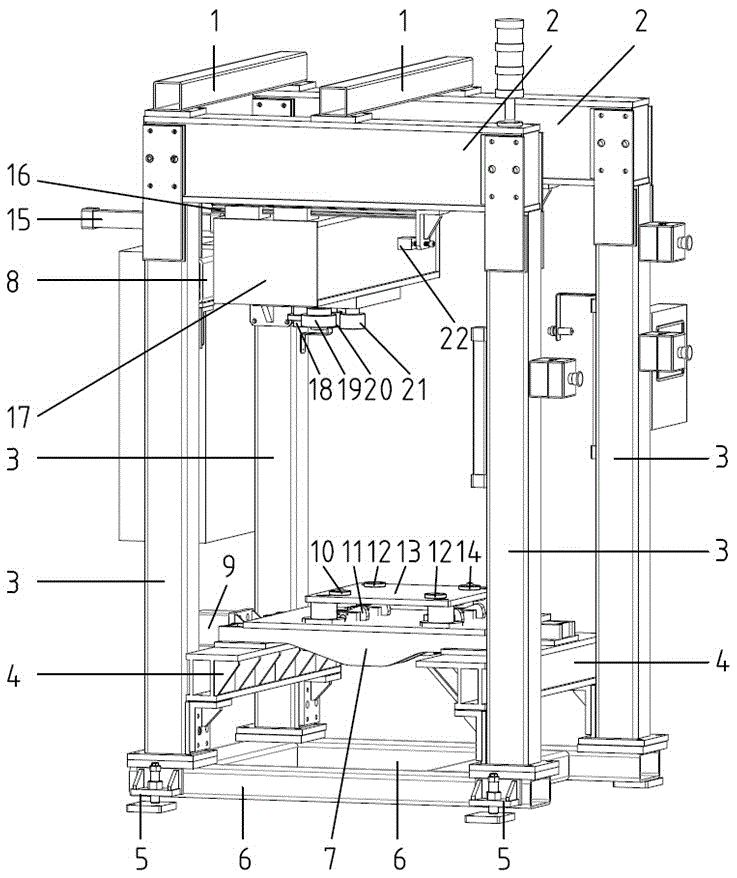

[0032] see figure 1 , figure 2 , a composite pressing device for on-line assembly of forklift gearboxes, including a frame, a moving pressure head mechanism installed at the upper end of the frame, and a lifting positioning mechanism installed at the lower end of the frame;

[0033] The frame is a cube frame, including four upright columns 3, two crossbeams 2, and an underframe. There is a connecting plate 1; the bottom frame is a rectangular frame, and the lower ends of the four columns 3 are respectively connected to the four corners of the bottom frame 6, and the bottoms of the four corners of the bottom frame 6 are respectively provided with leveling plates 5 through threaded connectors; The upper end of the column 3 of the frame is horizontally connected with a cylinder mounting seat 8, and the lower end of the column 3 of the frame is horizontally connected with two supports 4;

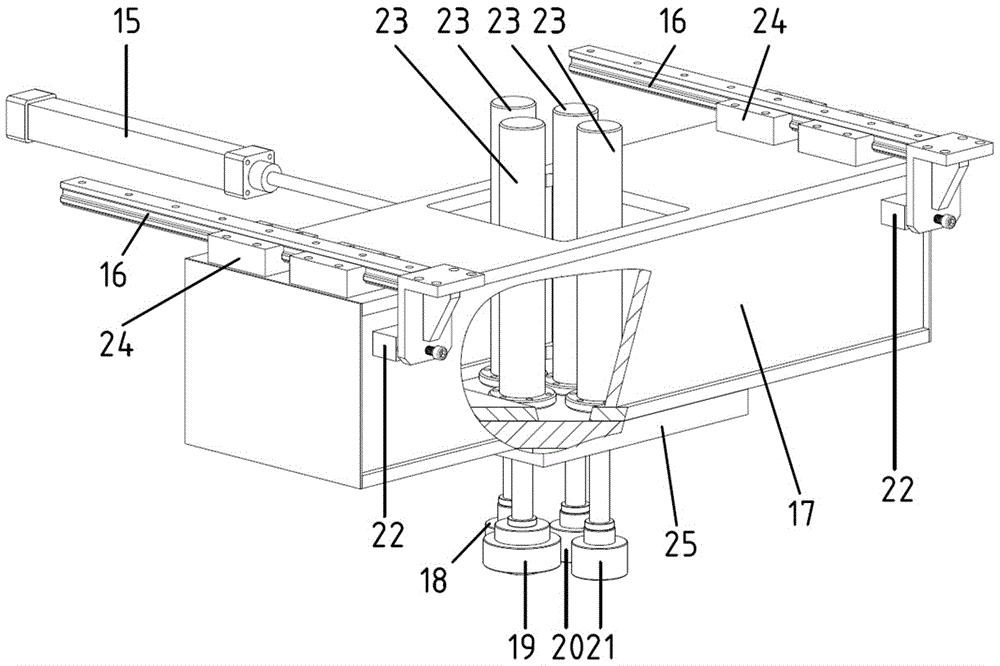

[0034] see image 3 , the moving head mechanism includes a mounting base 17 and a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com