Emulsion pump automatic assembling device

An automatic assembly device and emulsion pump technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as reduced assembly efficiency, and achieve the effects of improving press-fitting accuracy, improving stability, and reducing radial movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

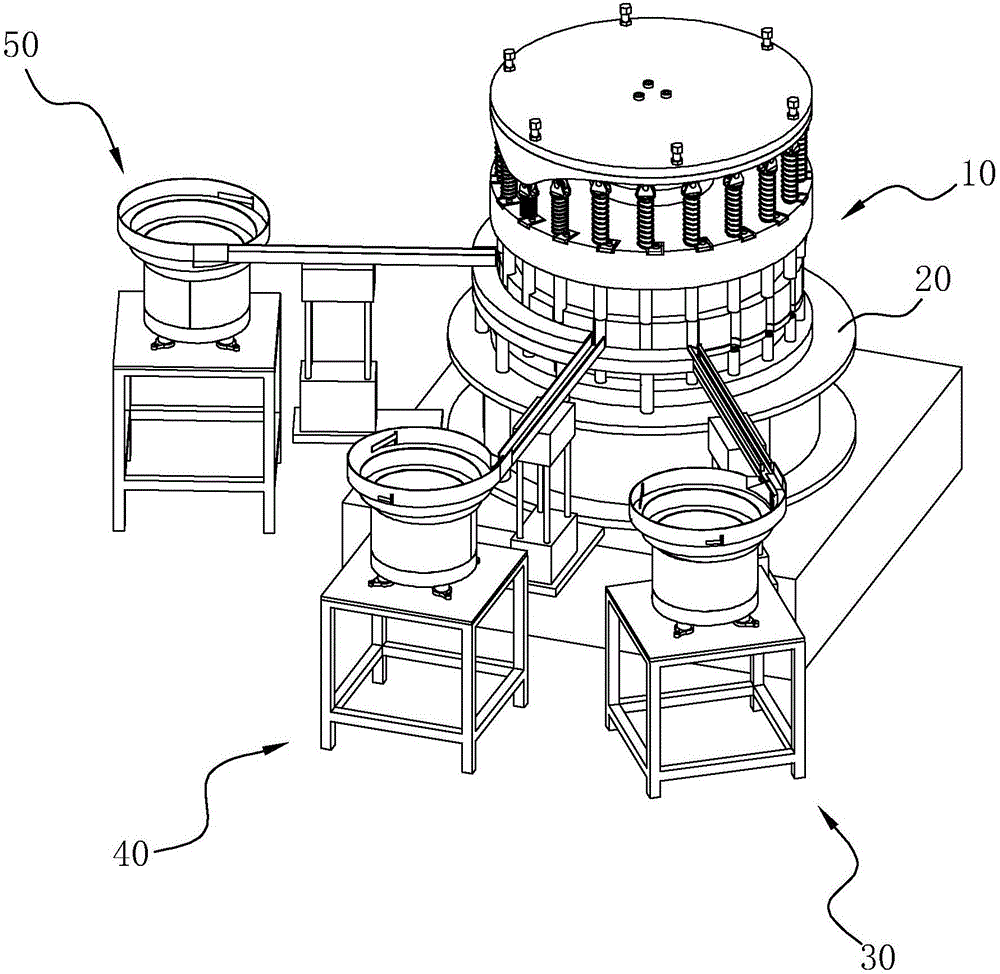

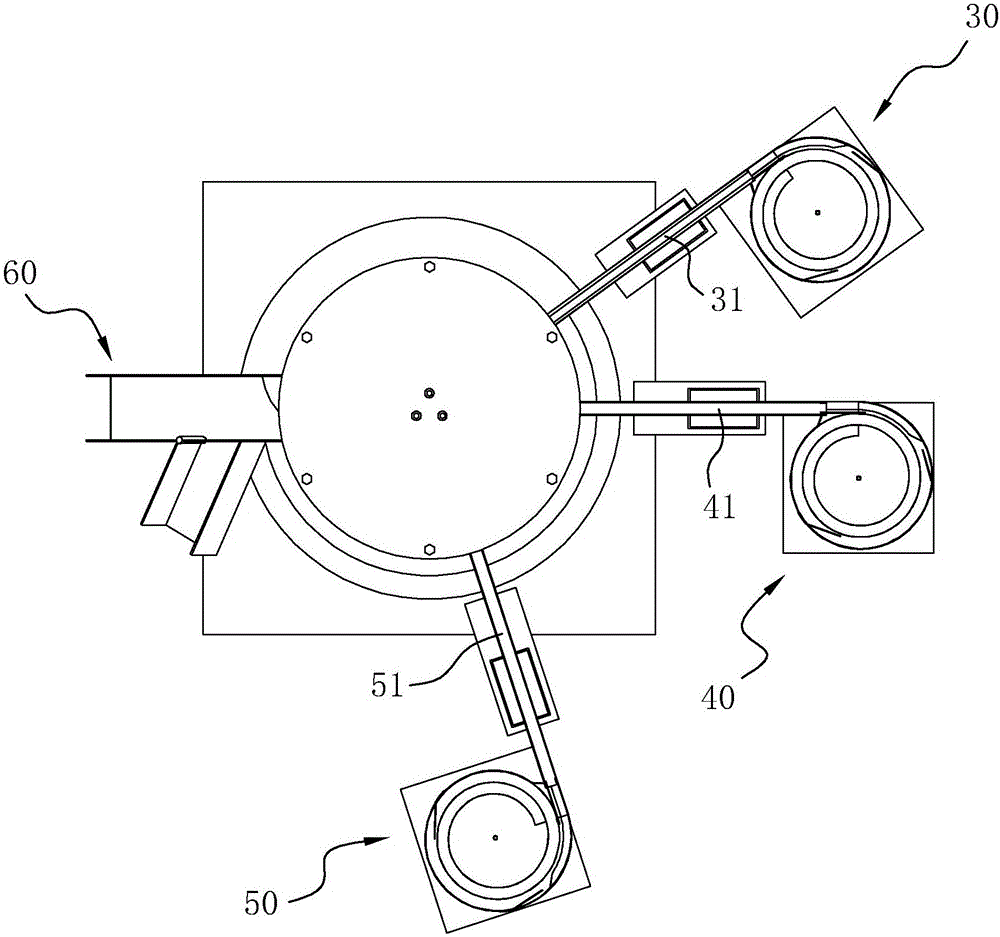

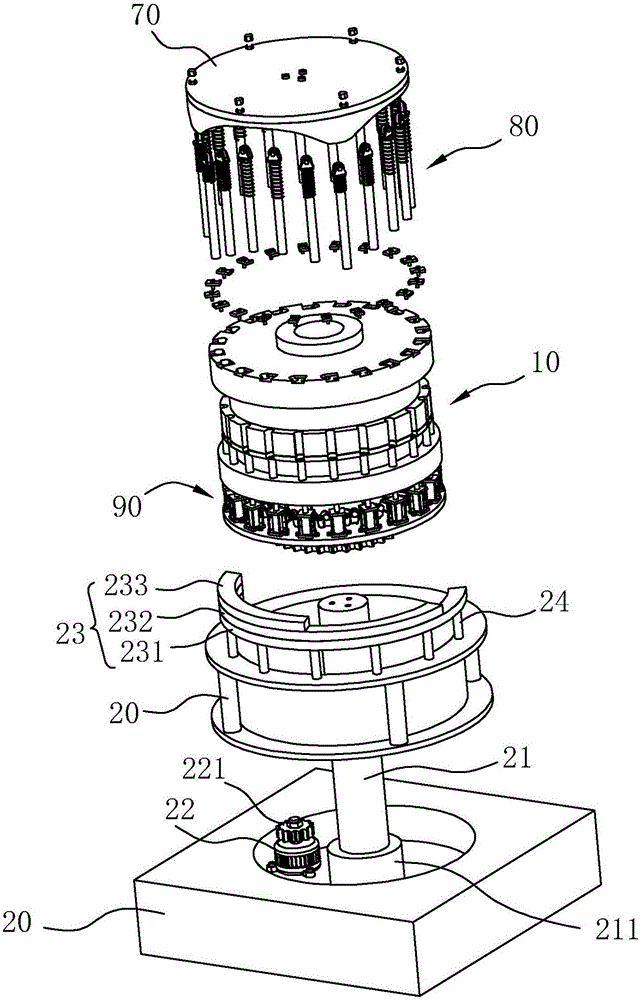

[0044] see figure 1 and figure 2 , an automatic assembly device for a lotion pump, comprising a frame 20, on which a substantially cylindrical rotary table 10 is arranged, and the rotary table 10 is driven on the frame 20 by a driving mechanism arranged in the frame 20 Turn on the spot. The pump body vibrating plate 30, the pressing head vibrating plate 40 and the cover vibrating plate 50 are also arranged on the upper edge of the frame 20, and the three are distributed around the rotary table 10 at a certain angle, wherein the first delivery on the pump body vibrating plate 30 The channel 31 , the second conveying channel 41 of the pressing head vibrating plate 40 and the third conveying channel 51 of the lid vibrating plate 50 all extend to the rotary table 10 , and transport the materials to be pressed to the rotary table 10 one by one. A discharge me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com