High-precision compression-configured device of electro-hydraulic servo valve armature component

An electro-hydraulic servo valve, high-precision technology, applied in hand-held tools, manufacturing tools, etc., can solve problems affecting product quality, assembly errors, and work efficiency reduction, so as to improve the quality of final products, reduce manual errors, and increase pressure. The effect of matching precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

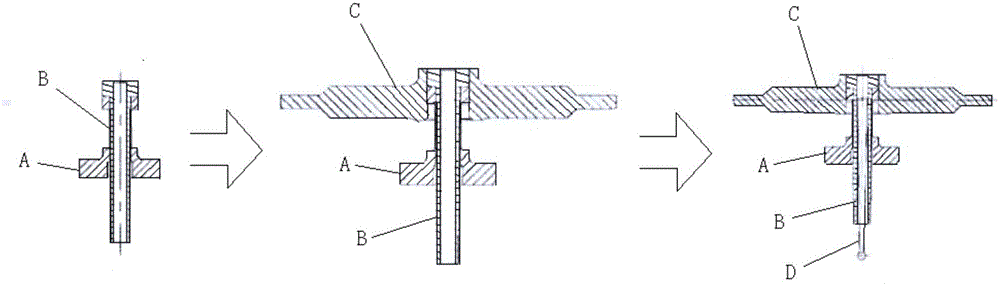

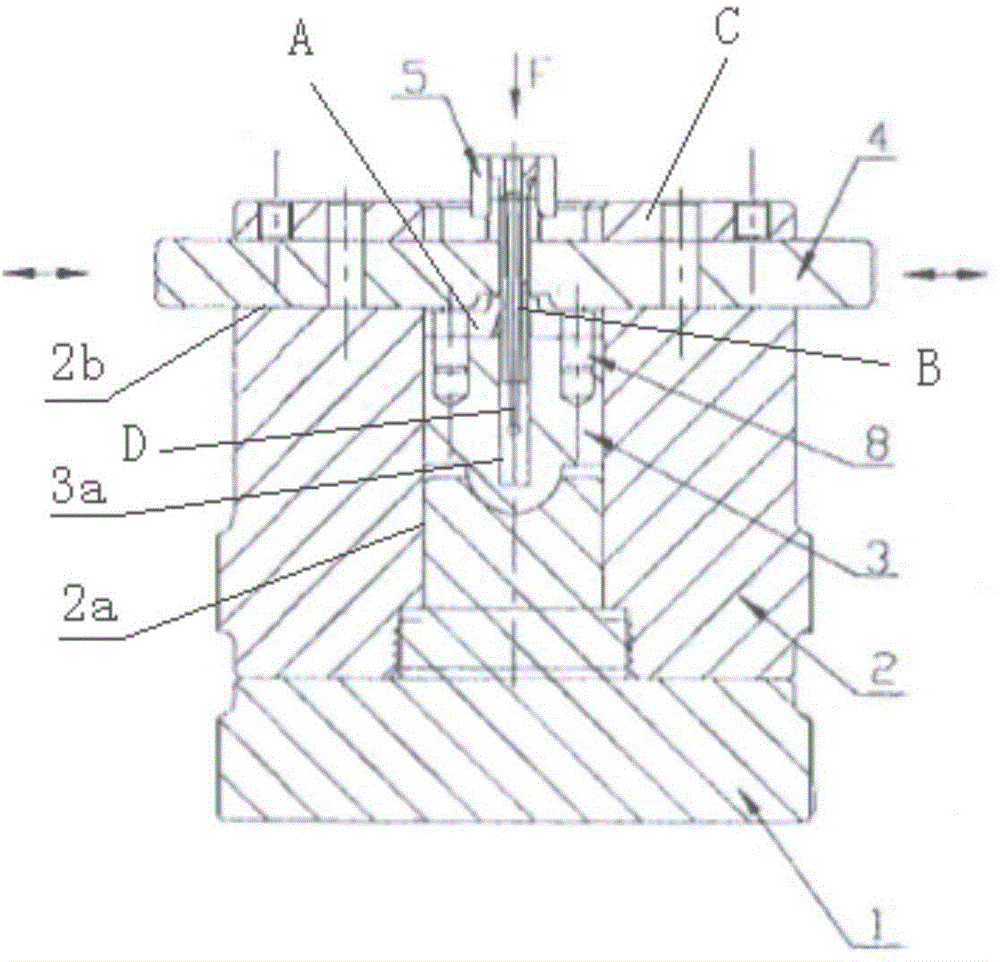

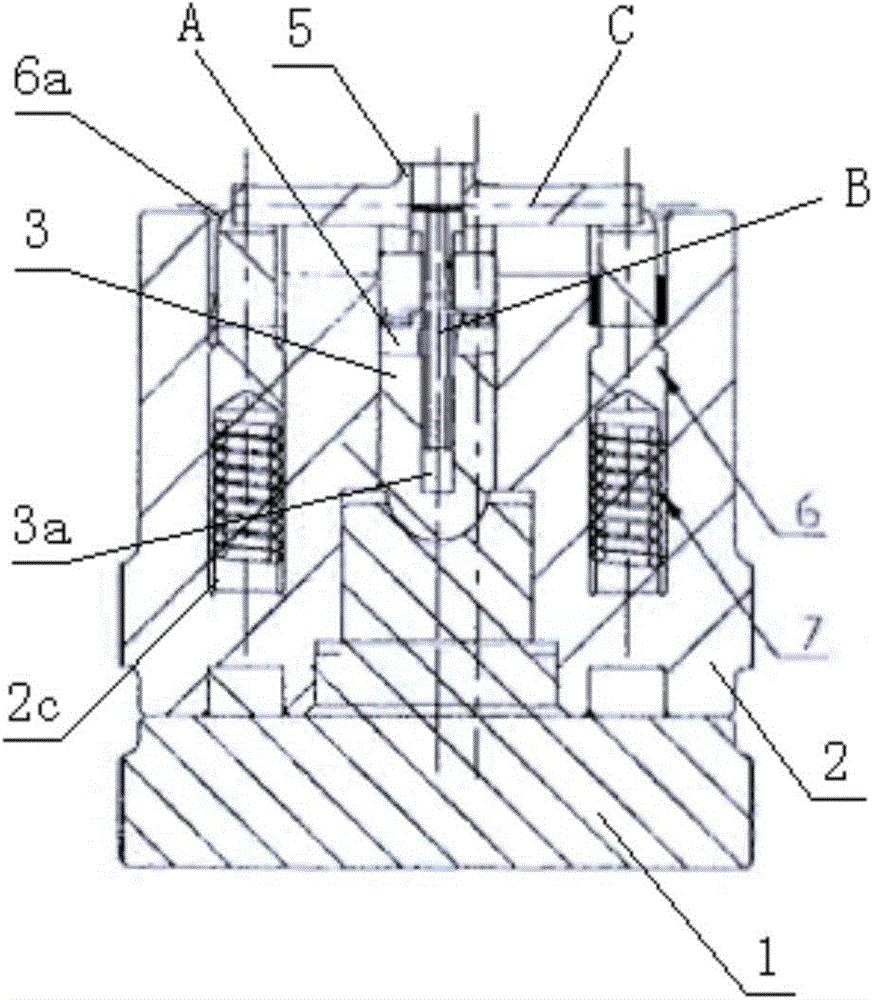

[0038] Example: Combine Figure 2~Figure 4 Shown is a specific embodiment of the high-precision press-fitting device for the armature assembly of the electro-hydraulic servo valve of the present invention, which mainly assists manual completion such as figure 1 The armature assembly shown ( Figure 2~4 In the press fit marked as 5), the armature assembly 5 includes sequentially press-fitted baffle A, tube spring B, armature C and feedback lever D, and its assembly structure is the existing conventional technology.

[0039] see details Figure 2~Figure 4 As shown, the high-precision press-fitting device for the armature assembly of the electro-hydraulic servo valve in this embodiment is composed as follows:

[0040] The central part 2 is a circular cylinder, and the center of the circular cylinder is provided with a longitudinal through hole 2a, and a positioning block 3 for placing and positioning the baffle A is provided in the hole, and a supply tube spring B is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com