PCB defect positioning method based on multi-template matching

A technology of PCB board and positioning method, which is applied in the direction of optical testing flaws/defects, image data processing, instruments, etc. It can solve problems such as poor robustness, high interference, and low efficiency, so as to improve accuracy, reduce matching errors, and improve accuracy. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

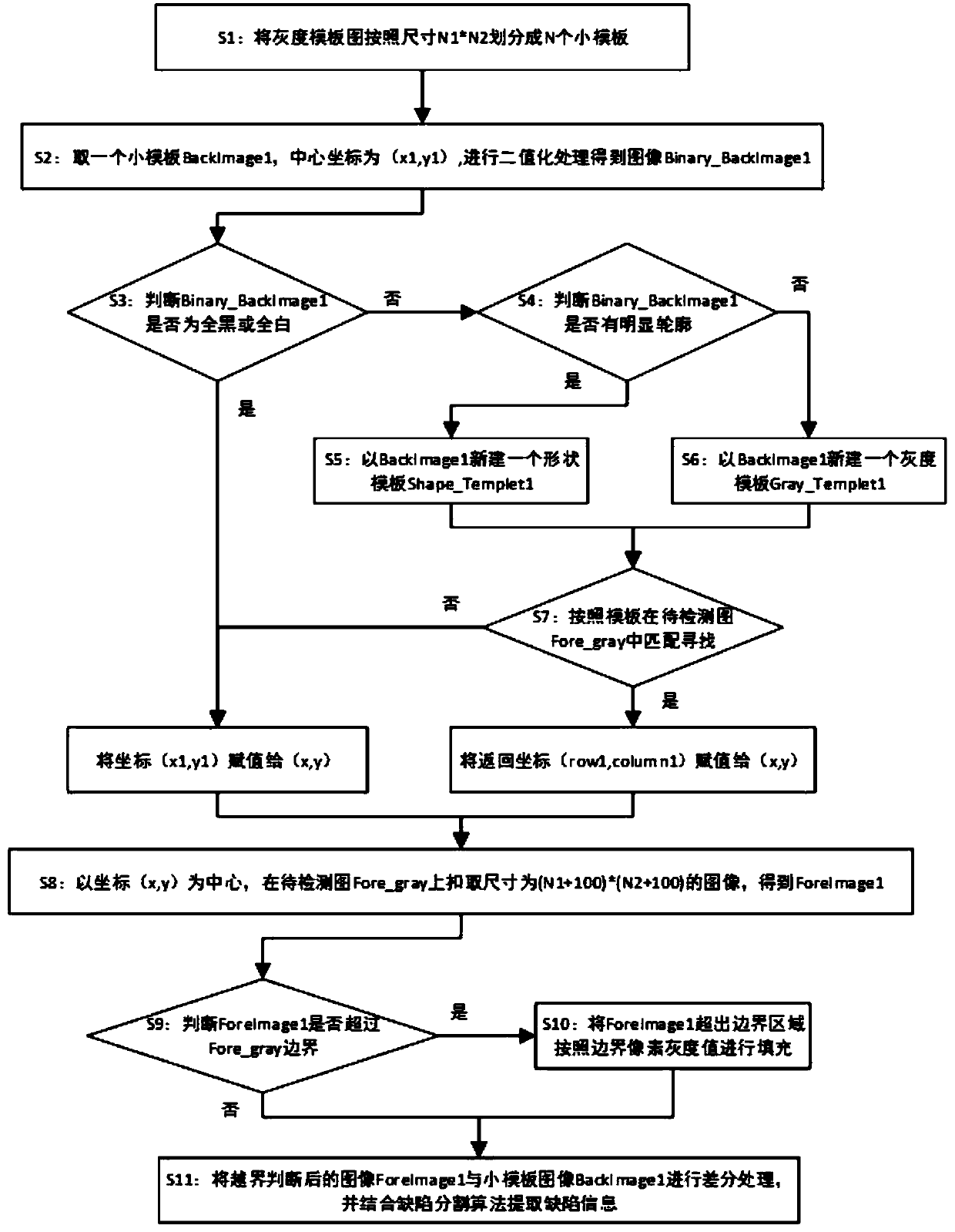

[0020] Embodiment: a PCB board defect location method based on multi-template matching.

[0021] S1, divide the grayscale template image Back_gray into a total of N small templates according to the fixed size N1*N2 (each small template has an overlapping area with the adjacent small template);

[0022] S2, take one of the small template images BackImage1, the center coordinates (x1, y1), and perform binary processing to obtain the image Binary_BackImage1;

[0023] S3, judging whether Binary_BackImage1 is completely black or completely white;

[0024] S4, if it is judged in step S3 that it is all black or all white, assign (x1, y1) to (x, y) if it is not all black or all white, then judge whether there is an obvious outline to Binary_BackImage1;

[0025] S5, if it is judged in step S4 that Binary_BackImage1 has an obvious outline, then create a shape template Shape_Templet1 with BackImage1;

[0026] S6, judging in step S4 that if Binary_BackImage1 has no obvious outline, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com