Method and device for optimizing chemical nickel-palladium-gold coating

A technology of chemical nickel and palladium, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve problems such as product hidden dangers, virtual soldering, open circuit, etc., to improve printing efficiency, avoid waste, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

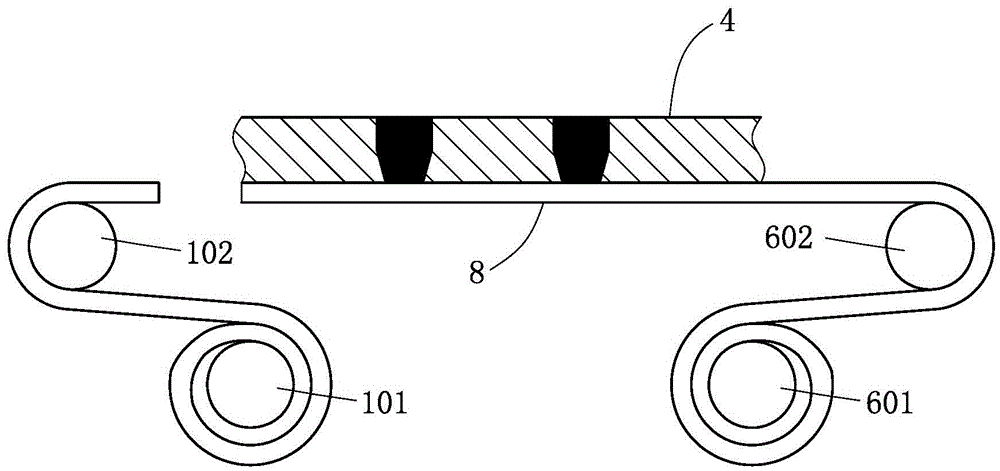

[0033]The invention provides a method for optimizing the chemical nickel-palladium-gold coating, comprising the following steps: (1) the lower surface of the steel template is covered with air-permeable cloth. Apply vaseline around the lower surface of the stencil to increase the combination of the air-permeable cloth and the steel stencil. The width of the air-permeable cloth needs to be equivalent to the surface area of the steel stencil. The specifications and parameters of the air-permeable cloth are not limited here, as long as it meets the air permeability and does not make the solder paste leak out. Yes, those skilled in the art can choose by themselves according to needs; (2) place the steel formwork on the workbench, which is provided with a gap matching the shape of the steel formwork, and when the steel formwork is transported to the position of the notch, the steel formwork The upper surface is attached to the lower surface of the workbench. There is a material bo...

Embodiment 2

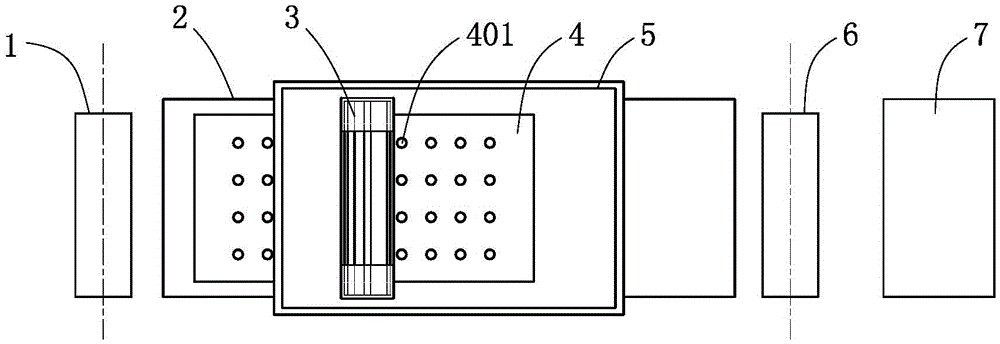

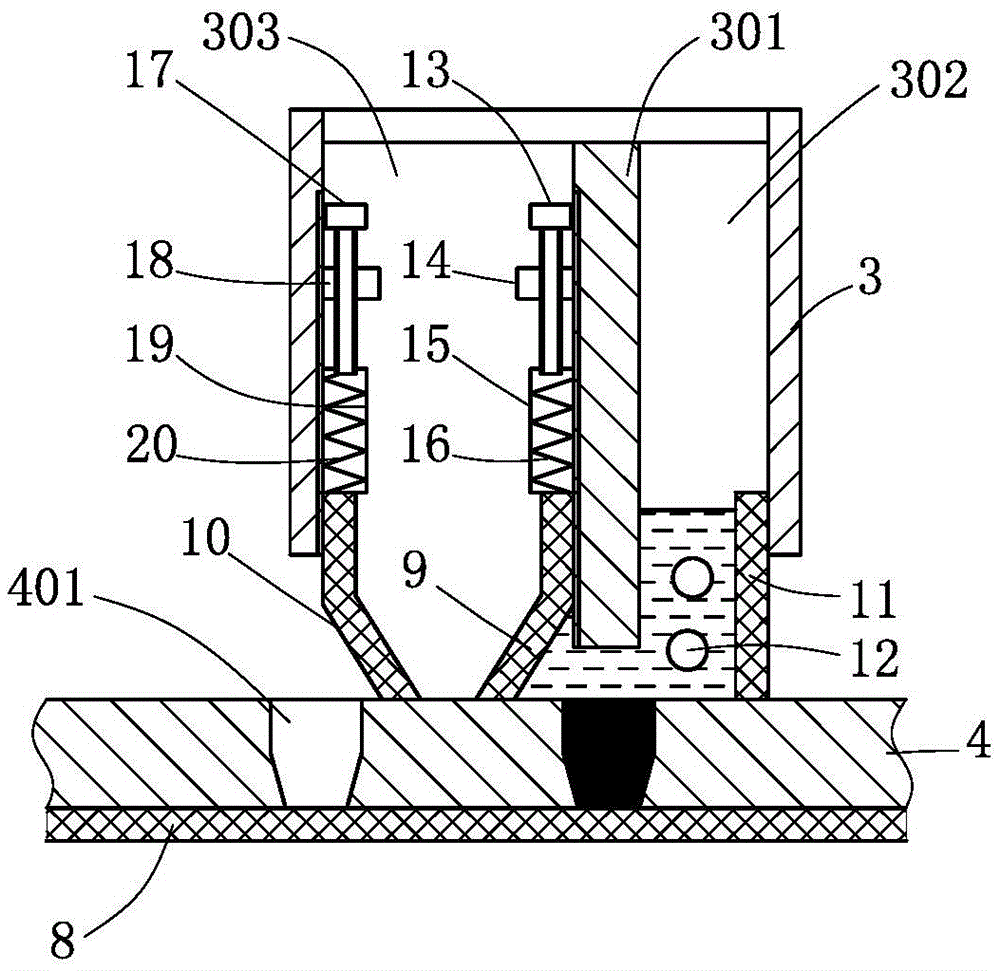

[0035] Such as figure 1 with figure 2 Commonly shown, the present invention also provides a kind of equipment of optimization chemical nickel-palladium-gold coating, comprises the film covering mechanism 1 that the lower surface of steel template 4 is covered with air-permeable cloth 8, before covering air-permeable cloth 8, needs to clean steel plate earlier The lower surface of the formwork 4, and then apply vaseline around the lower surface of the steel formwork 4 to increase the combination of the breathable cloth 8 and the steel formwork 4. The format of the breathable cloth 8 needs to be equivalent to the surface area of the steel formwork 4. It is not limited here, as long as the ventilation is satisfied without the solder paste leaking out, those skilled in the art can choose by themselves according to the needs, the downstream of the coating mechanism 1 is provided with a conveyor belt 2 for conveying the steel template 4, and the tail end of the conveyor belt 2 T...

Embodiment 3

[0045] Such as Figure 5 As shown, the present invention also provides a device for optimizing the chemical nickel-palladium-gold coating, the structure of which is basically the same as that of the second embodiment, including the technical solution of the second embodiment, and further improved on the basis of the second embodiment, specifically The scheme is as follows:

[0046] The workbench 5 is set in a closed ring shape, and flanges are provided on the inner and outer periphery of the workbench 5, and a motor is set at the center of the workbench 5 to drive the rotating shaft 21, and several support arms 22 are fixedly installed on the rotating shaft 21, A material box 3 is fixed on each support arm 22, and several tangentially arranged conveyor belts 2 are arranged on the workbench 5. Steel templates 4 are set on the conveyor belt 2, and a gap, the rotating shaft 21 rotates in one direction, which can drive the material box 3 to circulate to apply pressure to the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com