Flywheel clutch positioning pin pressing tool

A press-fit tooling and positioning pin technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of laborious operation for workers and low press-fit efficiency, and achieve good reliability, simple structure and good practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

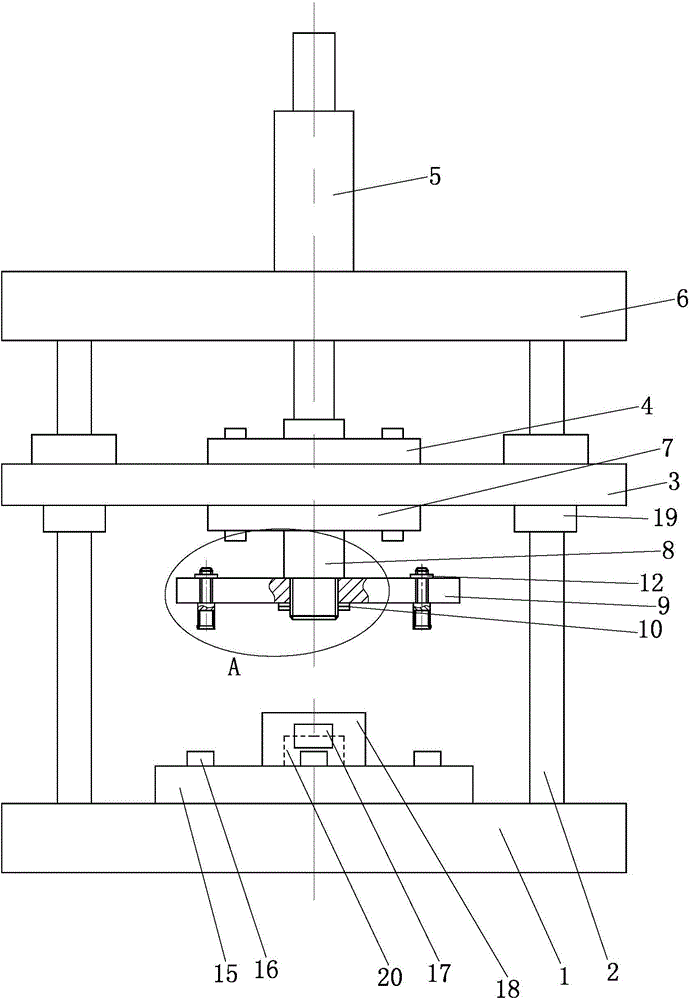

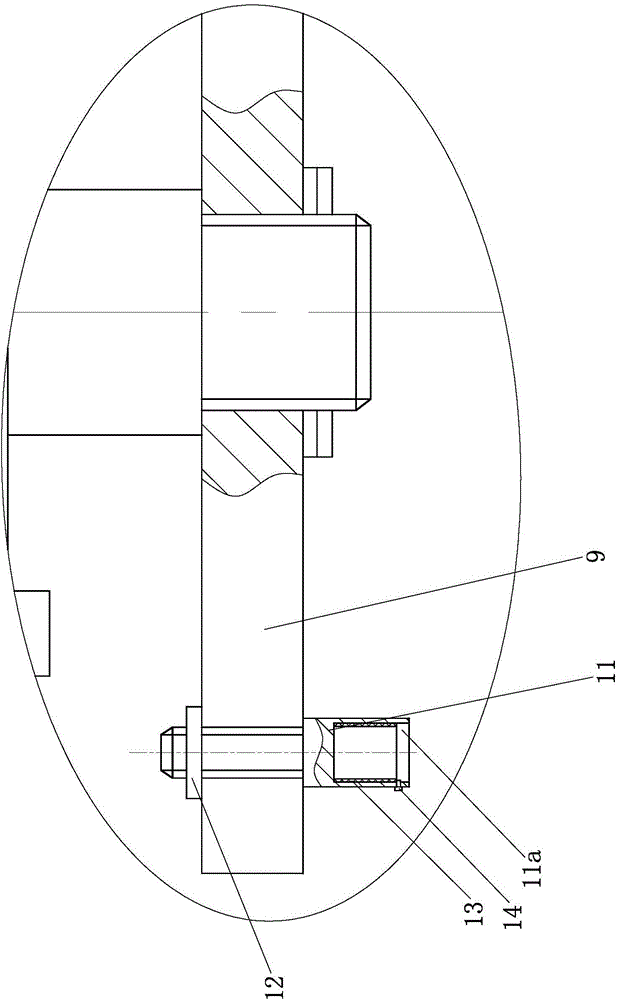

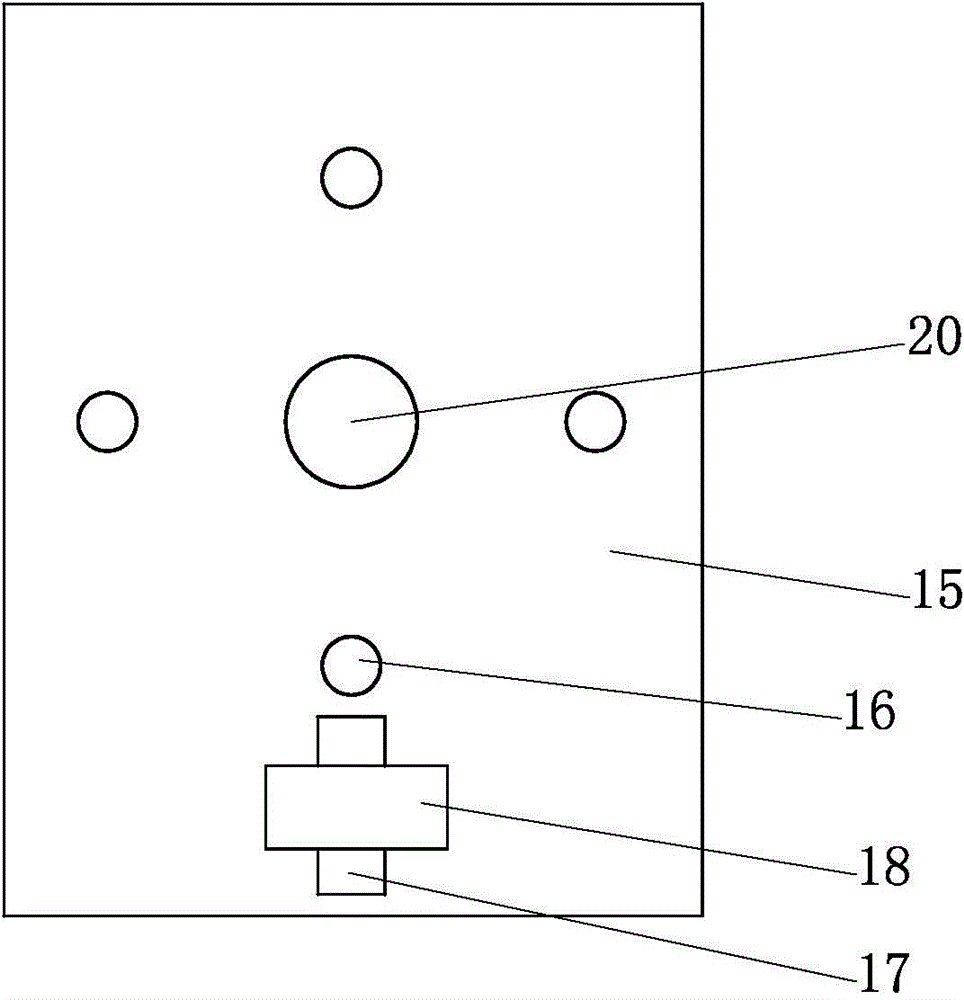

[0015] Such as figure 1 , 2 , 3, a flywheel clutch positioning pin pressing tool, mainly by the base 1, column 2, horizontal movable plate 3, upper connection plate 4, cylinder 5, top plate 6, lower connection plate 7, vertical shaft 8, press Disk 9, double nut 10, positioning pin connecting rod 11, lock nut 12, rubber sleeve 13, radial screw 14, backing plate 15, positioning pad 16, circumferential positioning block 17, mounting seat 18, sliding bearing 19 and The central positioning column 20 constitutes. Wherein, four columns 2 are fixedly arranged on the top surface of the base 1, and these four columns 2 are distributed on the four vertices of the same rectangle, and a horizontal movable plate 3 is connected between these four columns 2, and the horizontal movable Plate 3 is in sliding fit with column 2 . In this case, four sliding bearings 19 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com