Press mounting device for locating pin of fly wheel clutch

A press-fitting device and positioning pin technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve good practicability, good consistency, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

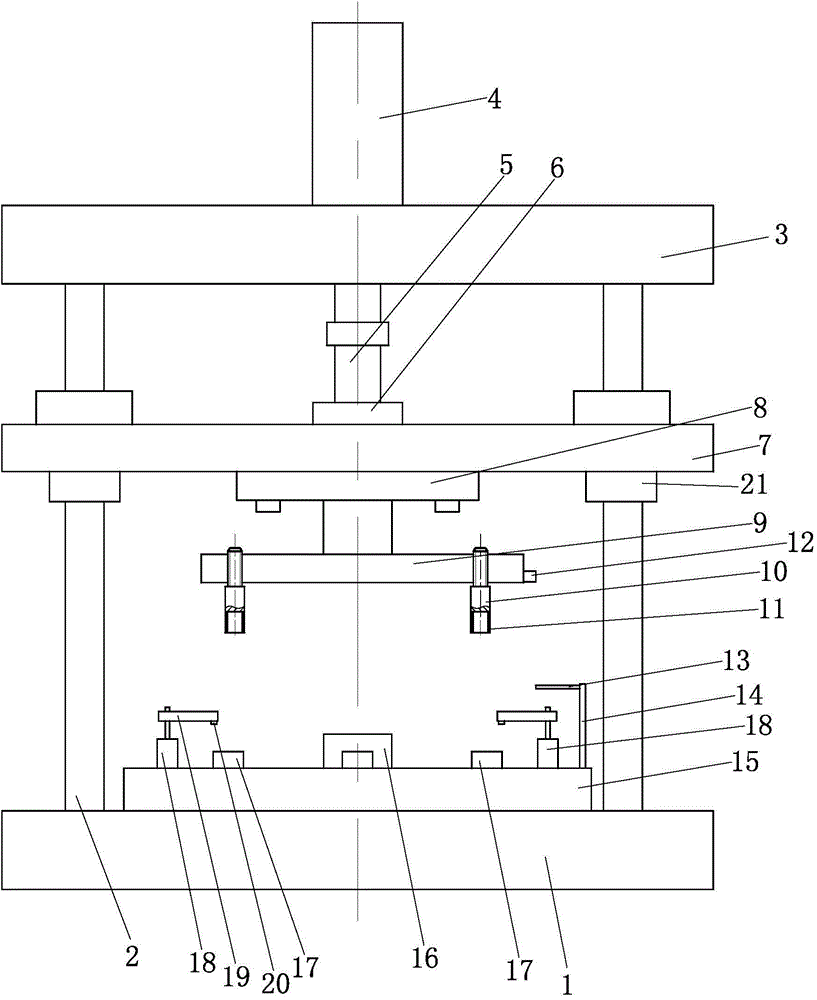

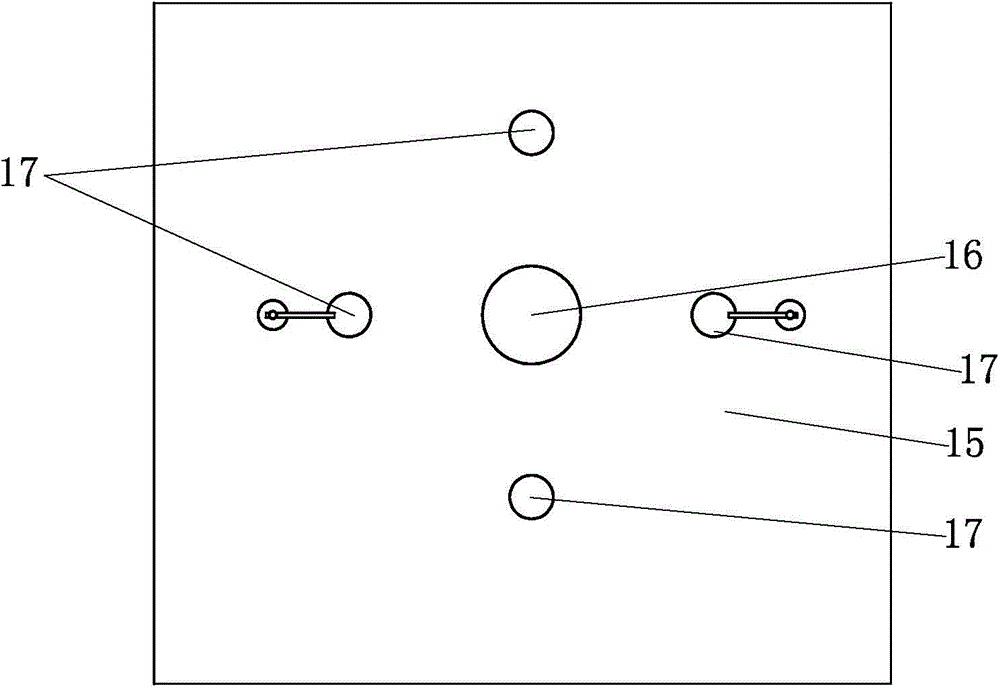

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0020] like figure 1 , 2 As shown, a flywheel clutch positioning pin pressing device mainly consists of a base 1, a column 2, a top plate 3, a servo motor 4, a screw 5, a screw nut 6, a lifting plate 7, a support plate 8, a pressing plate 9, Pressing rod 10, anti-drop cover 11, proximity switch 12, position detection block 13, support 14, backing plate 15, center positioning column 16, positioning pad 17 and flywheel pressing device constitute. Wherein, the base 1 is a structure arranged horizontally, four columns 2 are fixed on the top surface of the base 1, and the four columns 2 are distributed on four vertices of the same rectangle, and the tops of the four columns 2 are horizontally fixed with A top plate3. A servomotor 4 is vertically installed on the top plate 3 , the lower end of the output shaft of the servomotor 4 is coaxially connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com