Connector cable pressing jig

A connector and cable technology, which is applied in the field of connector cable crimping jigs, can solve the problems of long cable crimping time, staff fatigue, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

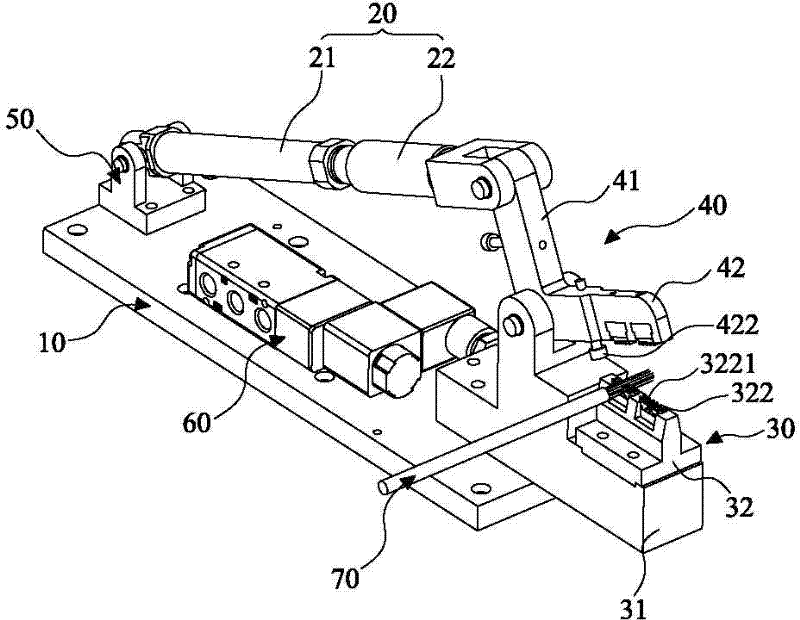

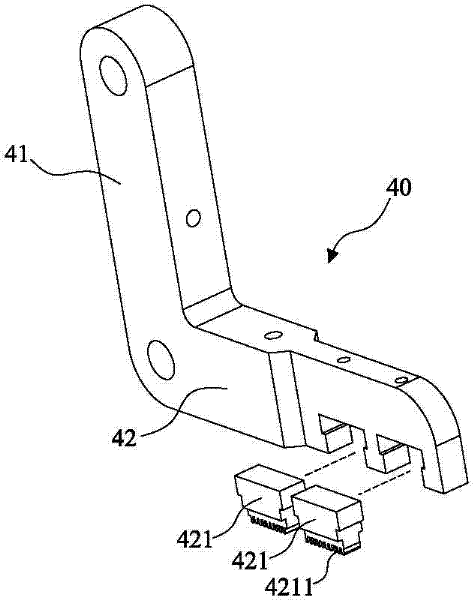

[0026] The present invention as Figure 1 to Figure 3 As shown, a base 10 , a cylinder 20 , a base 30 and a corner crimping rod 40 are included.

[0027] The base 10 is a flat plate, which is used to install the above-mentioned cylinder 20 and the base 30 , a connection seat 50 is arranged at one end of the base 10 , and a solenoid valve 60 for controlling the operation of the above-mentioned cylinder 20 is installed on the base 10 .

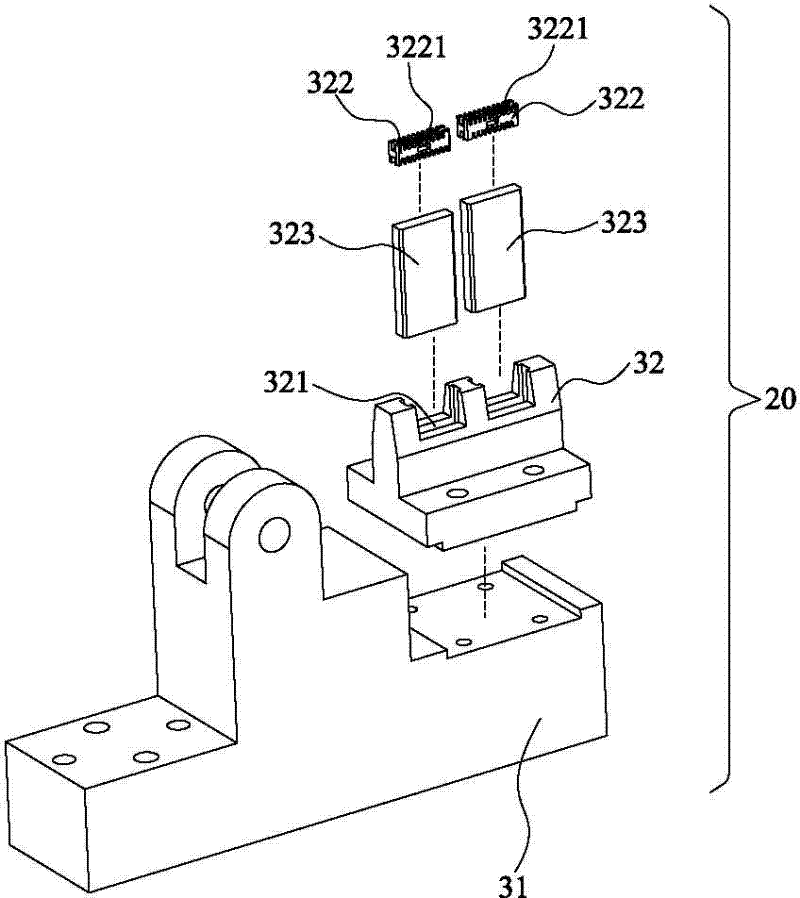

[0028] The cylinder 20 includes a cylinder main body 21 and a piston rod 22 , wherein one end of the cylinder main body 21 is pivotally connected to the connecting seat 50 , and the piston rod 22 is disposed at the other end of the cylinder main body 21 .

[0029] The base 30 is fixed on the other end of the base 10, and it includes a base 31 and a support base 32 replaceably mounted on the base 31. Two grooves 321 are arranged side by side on the support base 32. A replaceable wire rack 322 is accommodated in each groove 321, and a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com