Pressure filter and pressure filtration method thereof

A filter press and filter plate technology, which is applied in the field of press filter solid-liquid separation equipment, can solve the problems of high production and use costs, heavy equipment maintenance workload, rotten cloth and membranes, etc., so as to reduce production and operation costs, Less equipment maintenance workload and improved filter press efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

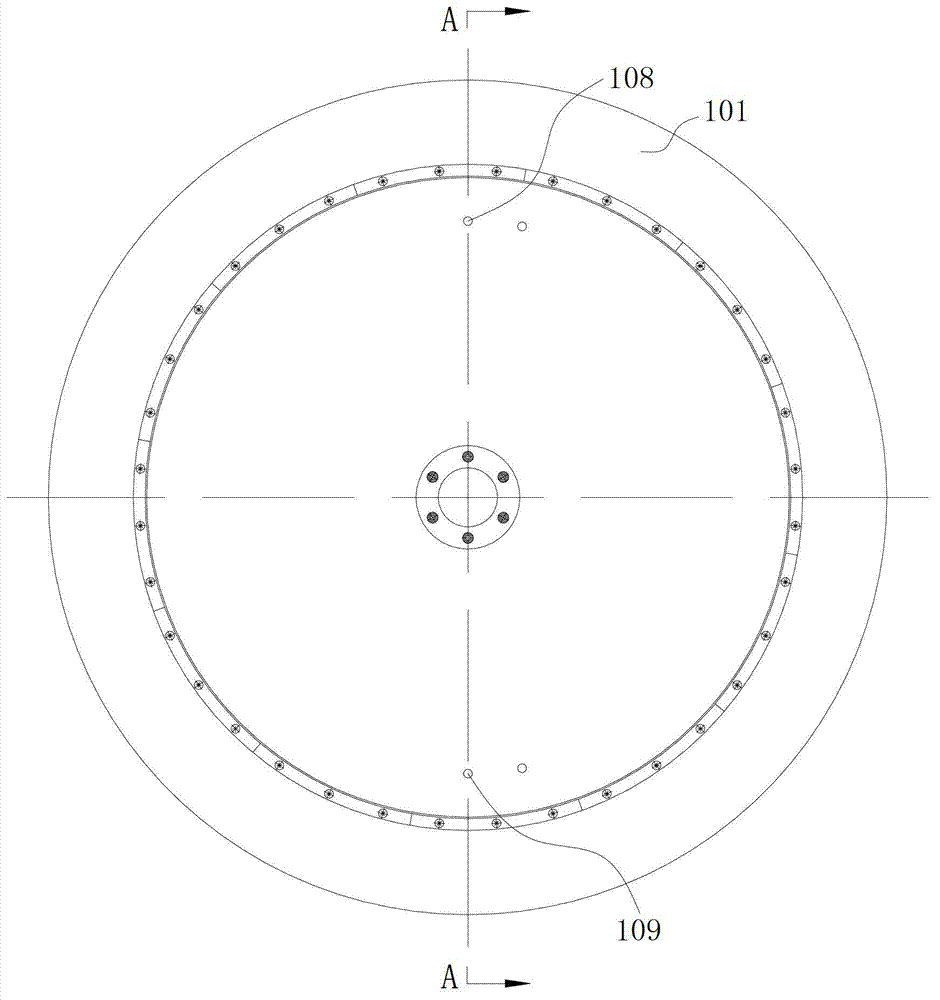

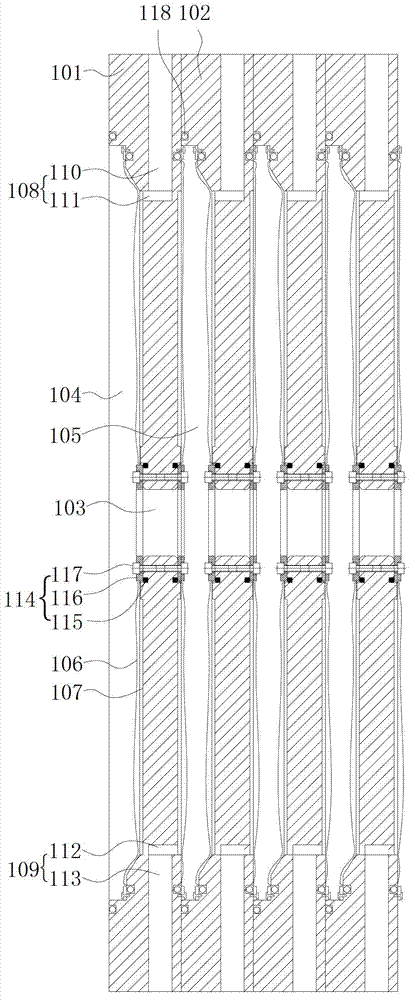

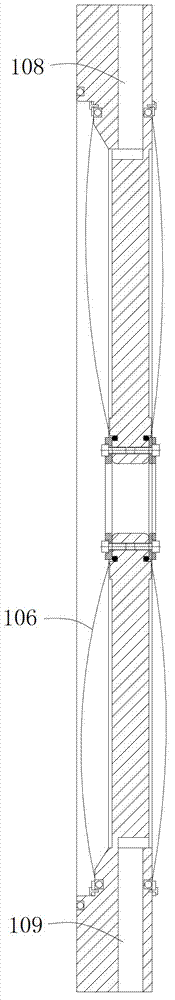

[0037] Such as figure 1 , figure 2As shown, the structure of a filter press comprising four filter plates is shown, and every two of the four filter plates are connected end to end, and the four filter plates are respectively the first filter plate 101, the second filter plate 102, and the third filter plate , the fourth filter plate, each filter plate has the same structure. Taking the first filter plate as an example, the first filter plate 101 is a circular filter plate, one side of which is provided with a groove inward, and the mouth of the groove is inclined at an obtuse angle to the bottom, and the groove is used as the first filter press space 104, open a through hole in the other side of the filter plate that communicates with the bottom of the groove, as the material passage 103, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com