Feeding cutting and pressing binding device of flexible iron base thin belt material

A thin tape and pressing technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of unsatisfactory, waste of excess materials, and uncompact equipment structure, etc., achieve compact structure of the device, realize automatic production, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

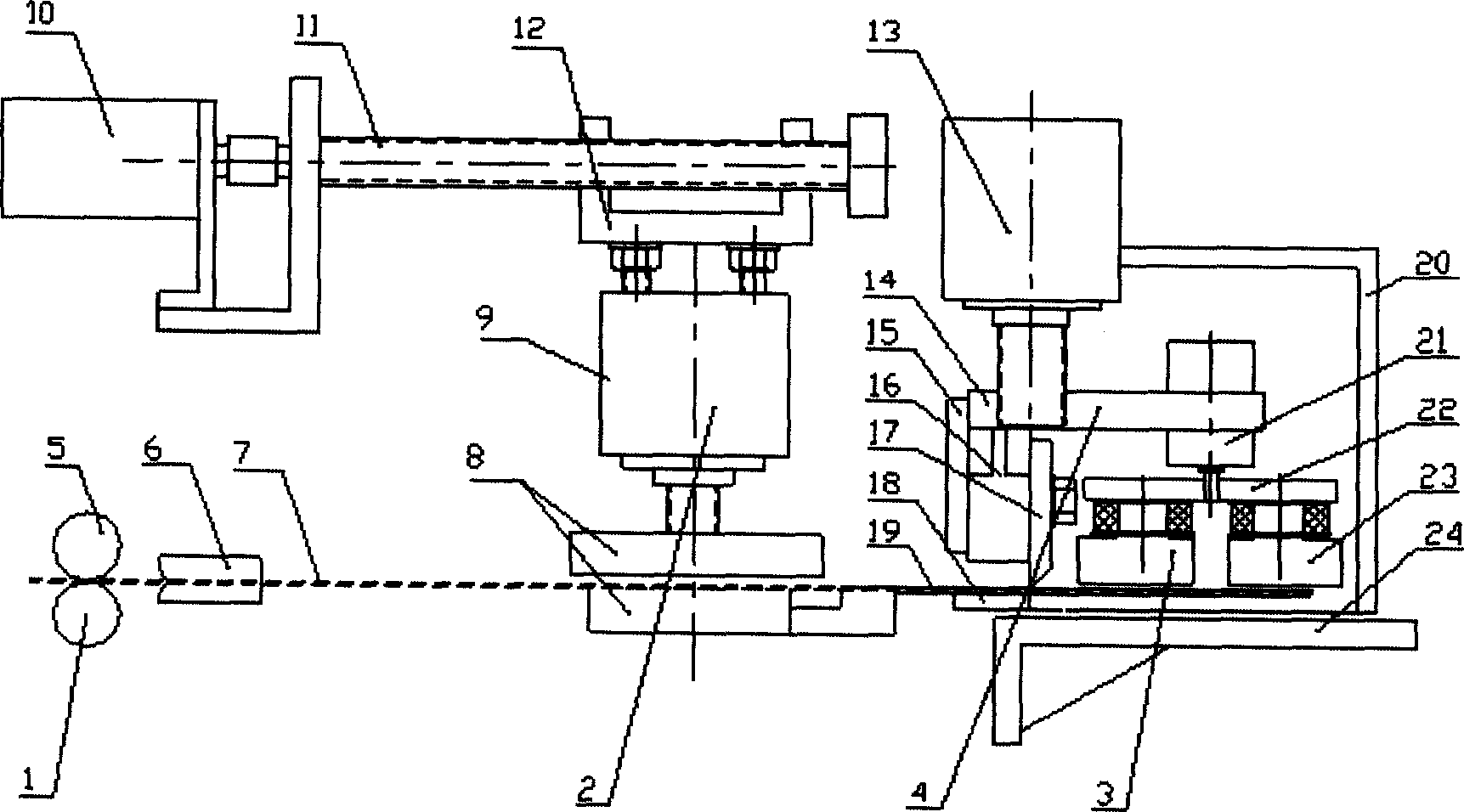

[0014] Such as figure 1 As shown, the present invention includes: a strip shaping component 1, a strip guiding and pinching component 2, a strip electromagnetic suction and transfer component 3, and a strip cutting and pressing component 4.

[0015] The strip shaping component 1 is composed of two cylindrical rubber rollers 5 placed close to each other, and is arranged at the inlet of the strip 7 of the entire device;

[0016] The strip guiding and pinching component 2 includes: a guide plate 6, a clamping plate 8, a clamping cylinder 9, a driving motor 10, a transmission mechanism 11, a sliding block 12 and a supporting carrier plate 19, and the connection relationship is: the guide plate 6 It is composed of two thin plates dug with multiple parallel and evenly distributed guide grooves facing each other; the clamping plate 8 has two upper and lower plates, the lower plate is fixed relative to the cylinder body of the clamping cylinder 9, and the upper plate is driven by the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com