Intelligent mechanical automatic transferring device

An intelligent mechanical and active technology, applied in the field of machinery, can solve the problems of limited space, lack of coherence between turning equipment and conveying equipment, and inability of turning equipment to realize conveying operations, etc., to achieve the effect of convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

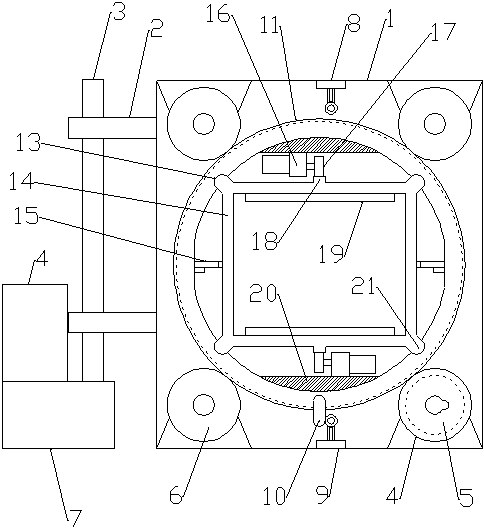

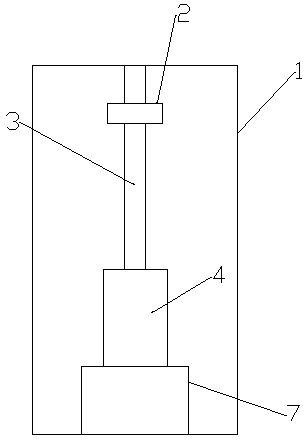

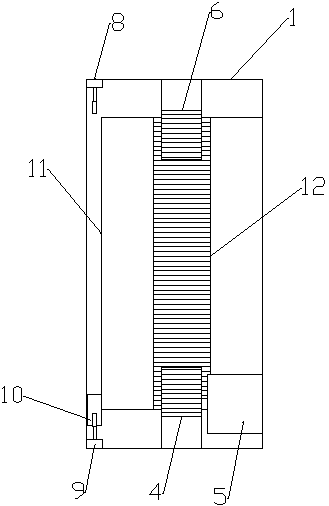

[0022] like figure 1 , 2 , 3, 4, 5, 6, and 7, an intelligent mechanical automatic reprinting device, including a reprint frame 1, a reprint rotating shaft 3 connected to the reprint frame 1 through a reprint bracket 2, the bottom of the reprint rotating shaft 3 and the deceleration The output end of machine 7 is fixedly connected, and the output end of reprinting motor 4 is connected with the input end of speed reducer 7, and in described reprinting frame 1, a turning and transferring device is installed, and turning and transferring device and reprinting motor 4 are connected with each other through wires. The controller is connected. The controller is connected with external equipment and installed on the outside of the device. It can be set remotely or near the device to facilitate maintenance. The turning and transferring device includes a turning cylinder 11 arranged in the transfer frame 1, a driven limit support gear 6 and a driving rotation gear 4 are arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com