Patents

Literature

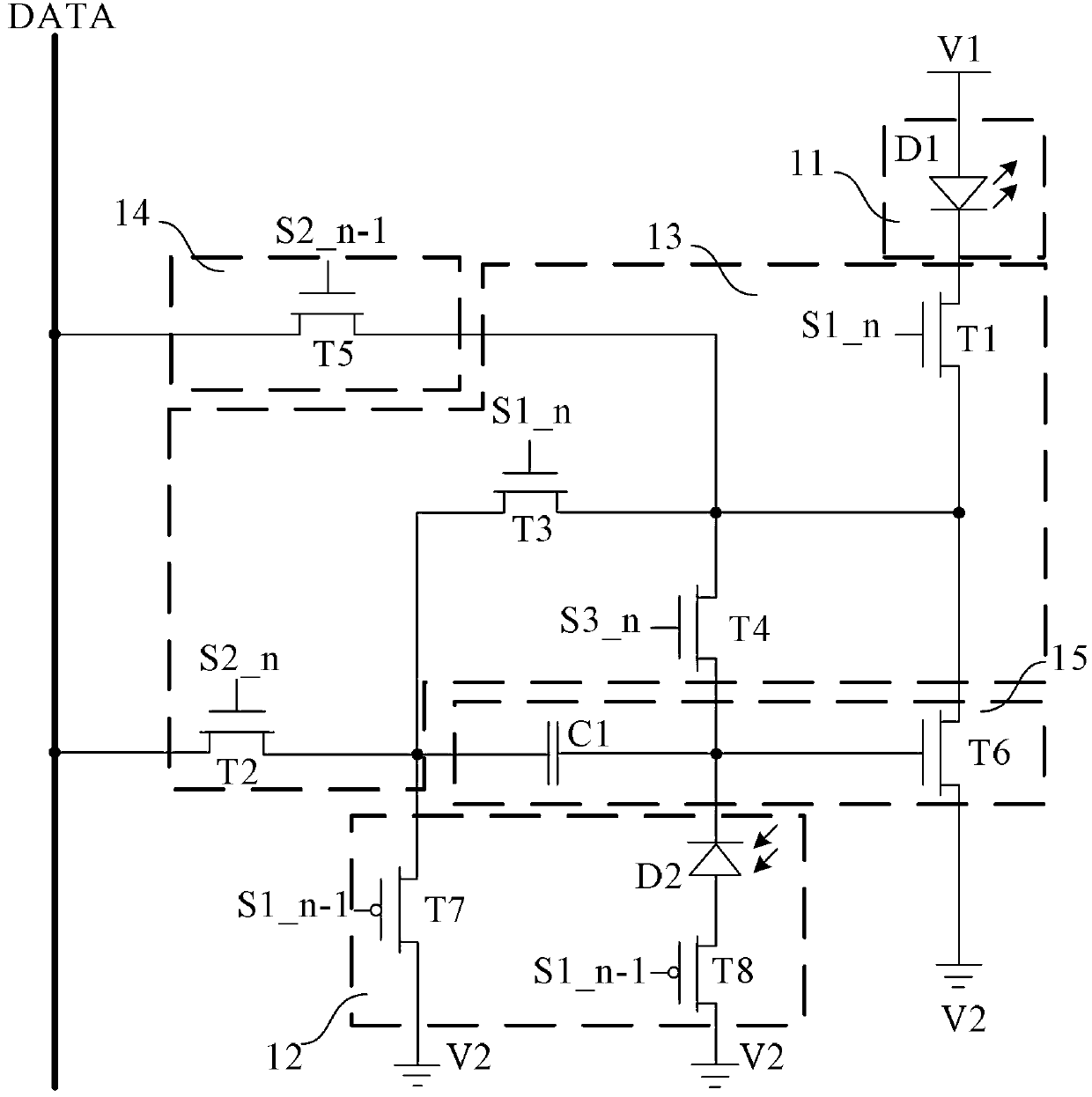

37results about How to "Simultaneous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing gamma-amino butyric acid through enzymatic conversion

InactiveCN1635128ASimultaneous productionStrong specificityFermentationGlutamate decarboxylaseCombined method

The invention discloses an enzyme conversion method for preparing gamma-butyric acid. The preparation method comprises employing two mixed acidic amino acids of L-glutamic acid and L-aspartic acid as raw material, mixing the cells of Escherichia.coli AS1.505 with highly active L-glutamic acid decarboxylases and the conversion liquid containing the mixture of L-glutamic acid and L-aspartic acid, implementing enzymatic reaction under the temperature of 28~45íµ, then separating the conversion products by isoelectric point crystallization process or isoelectric point crystallization and ion exchange resin combined method to obtain high purity gamma-butyric acid and L-aspartic acid. The invention solves the problem of the highly effective separation of two acidic mixed amino acids, and obtains gamma-butyric acid with higher additional value, and has advantages of low price, simple operation, short conversion time, and low production cost.

Owner:NANJING UNIV

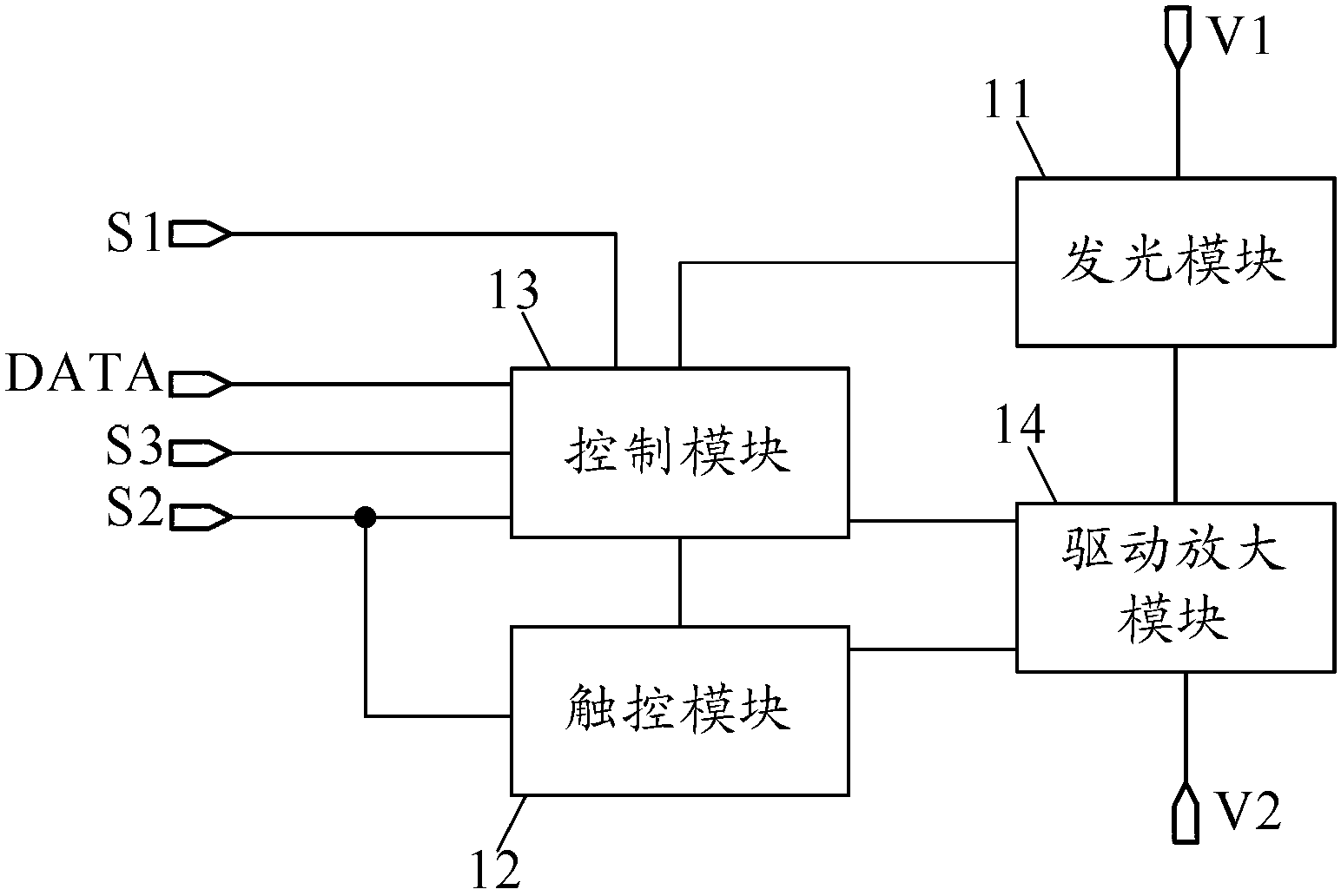

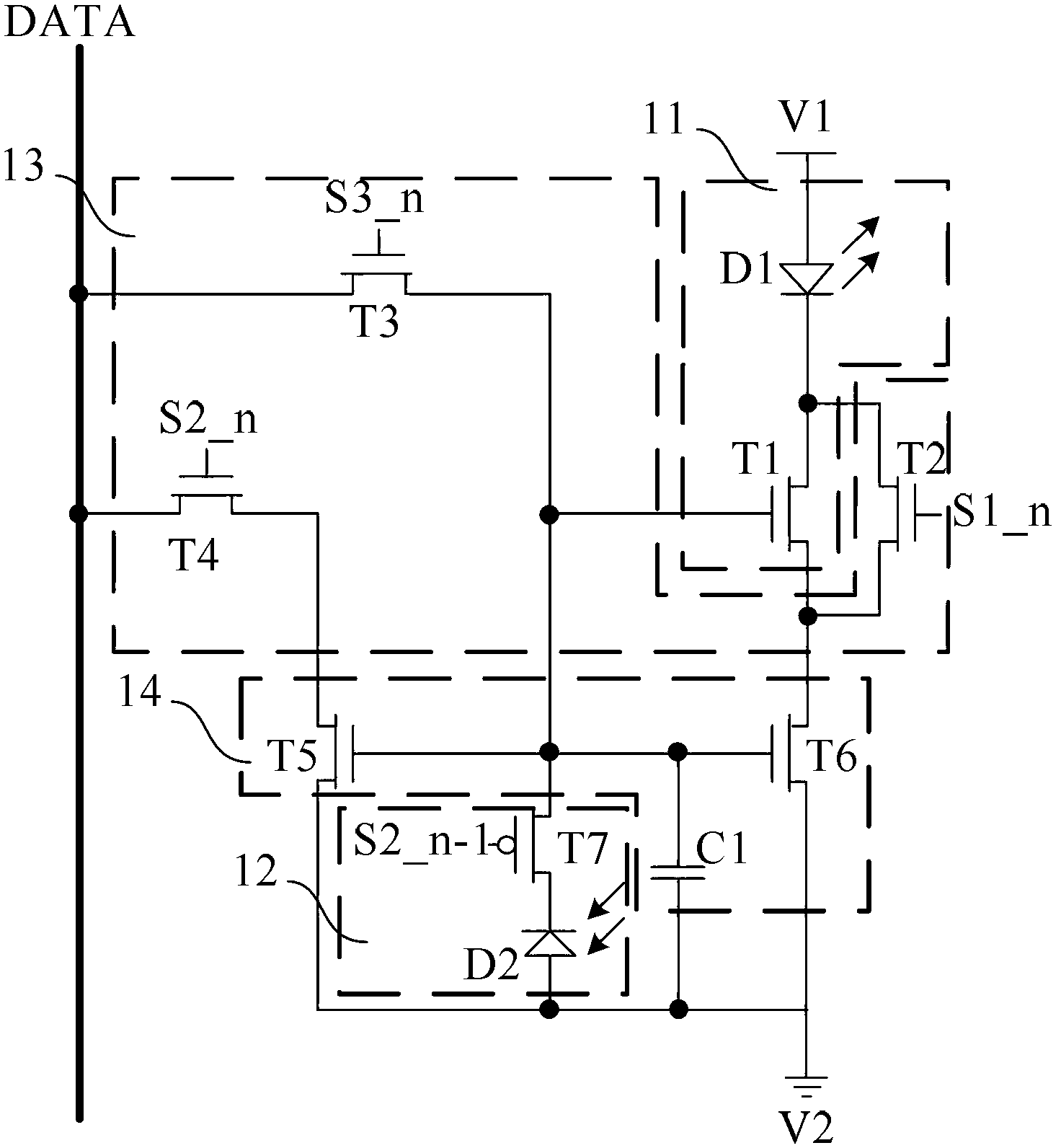

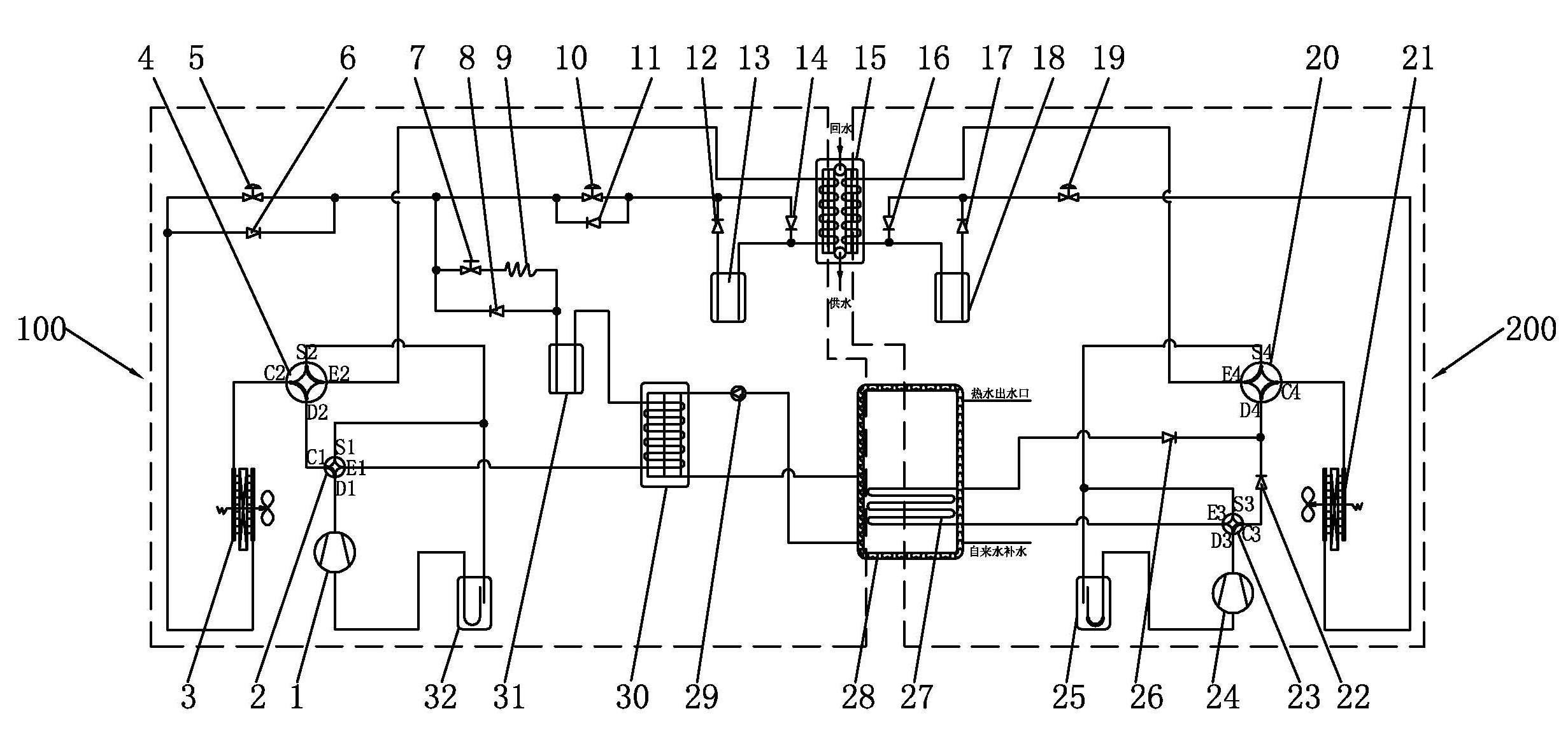

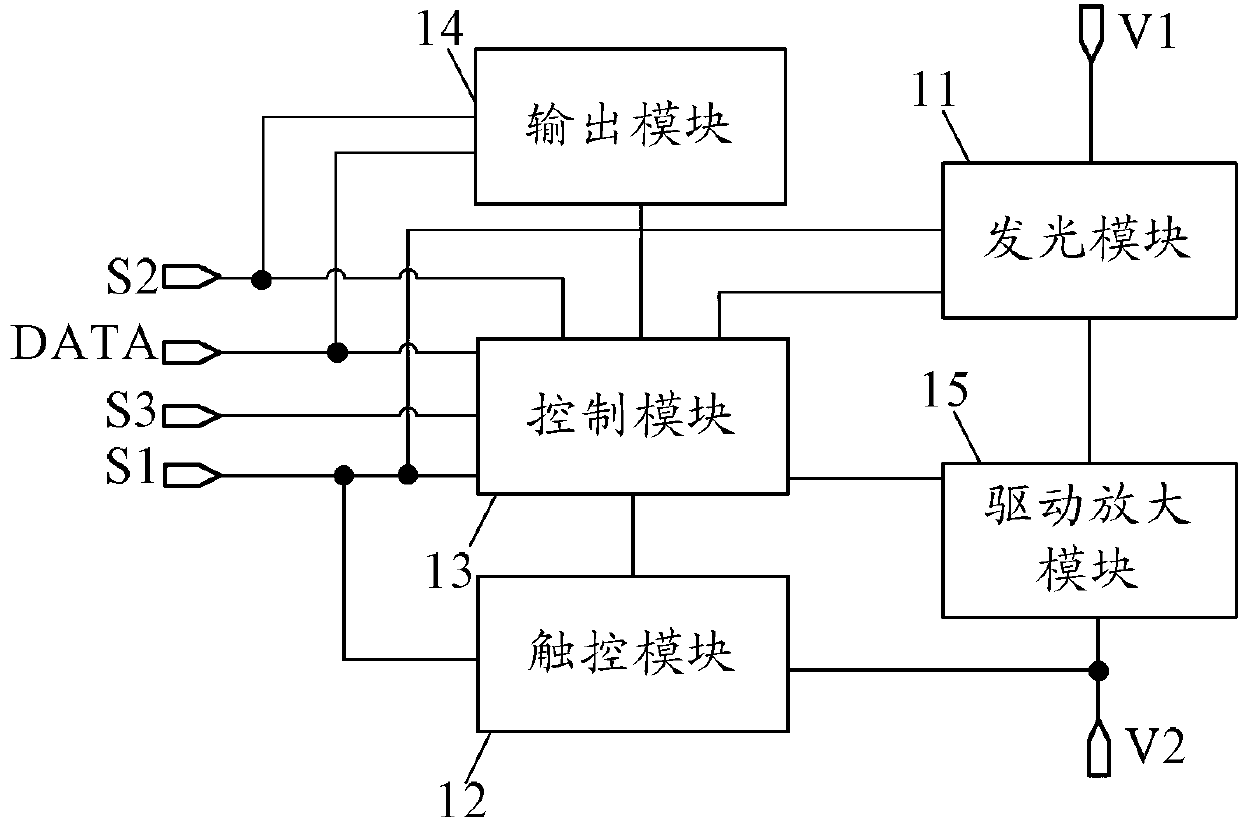

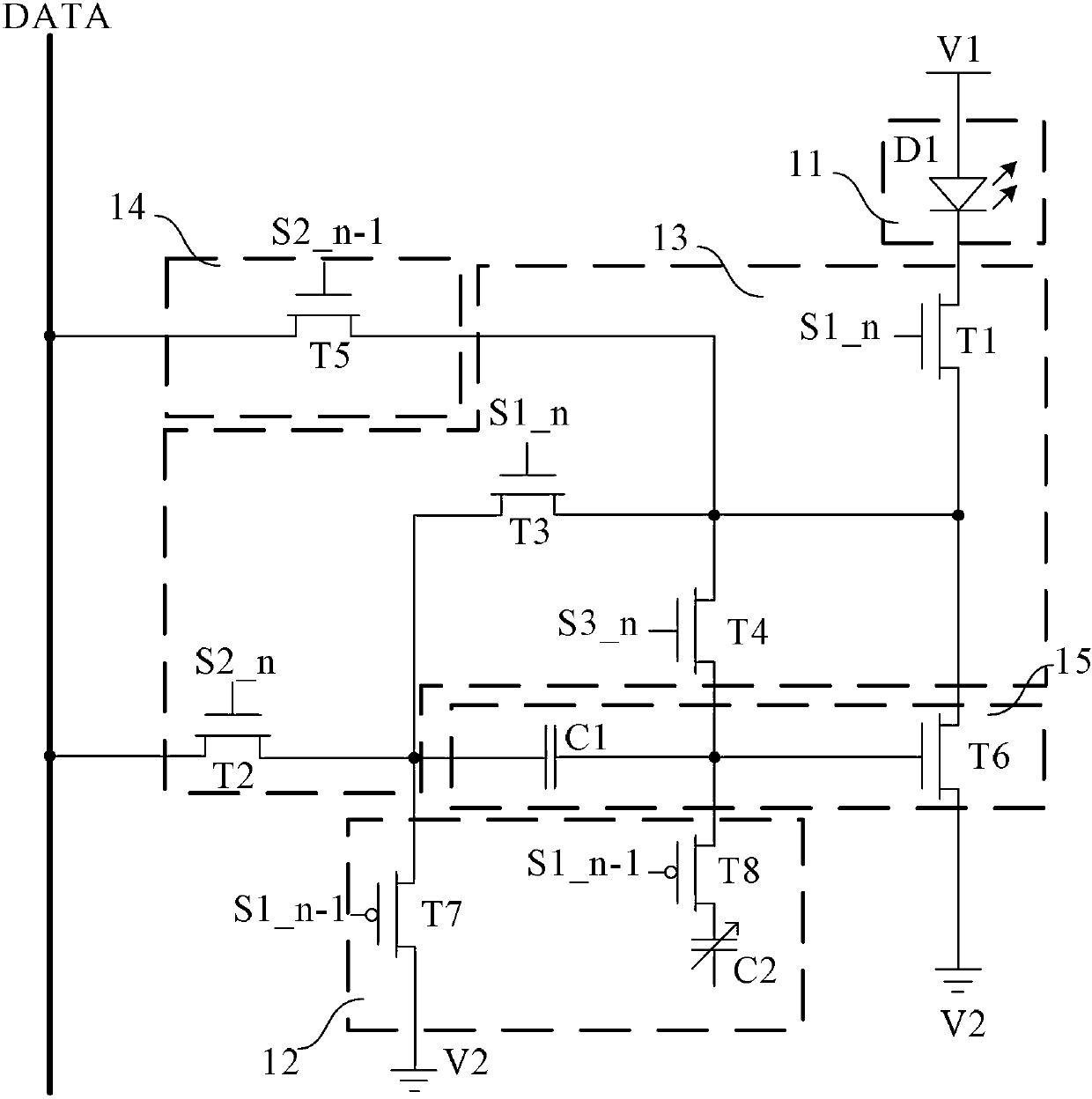

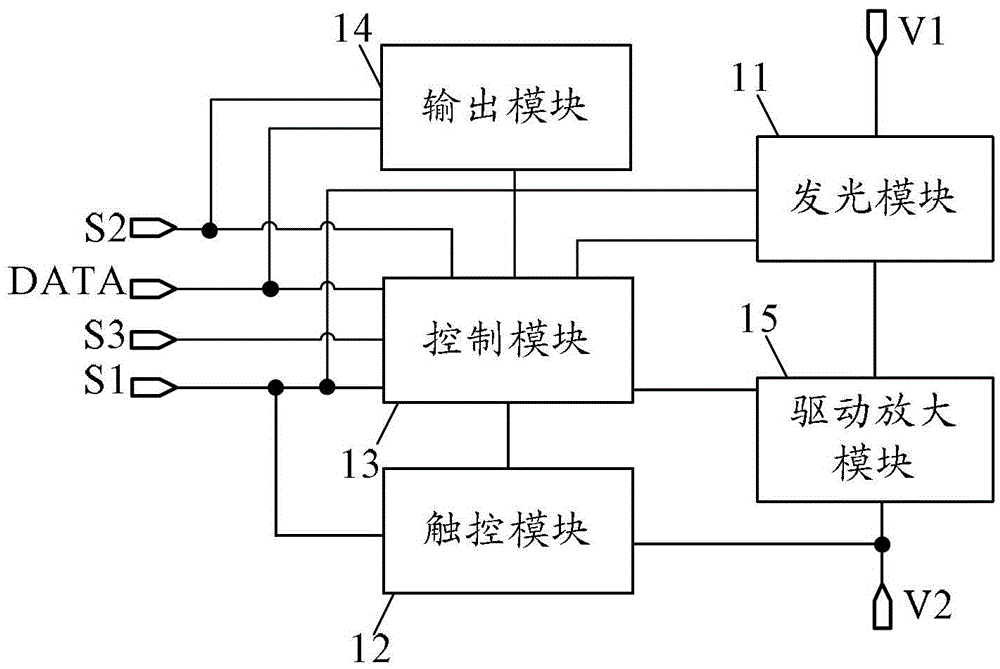

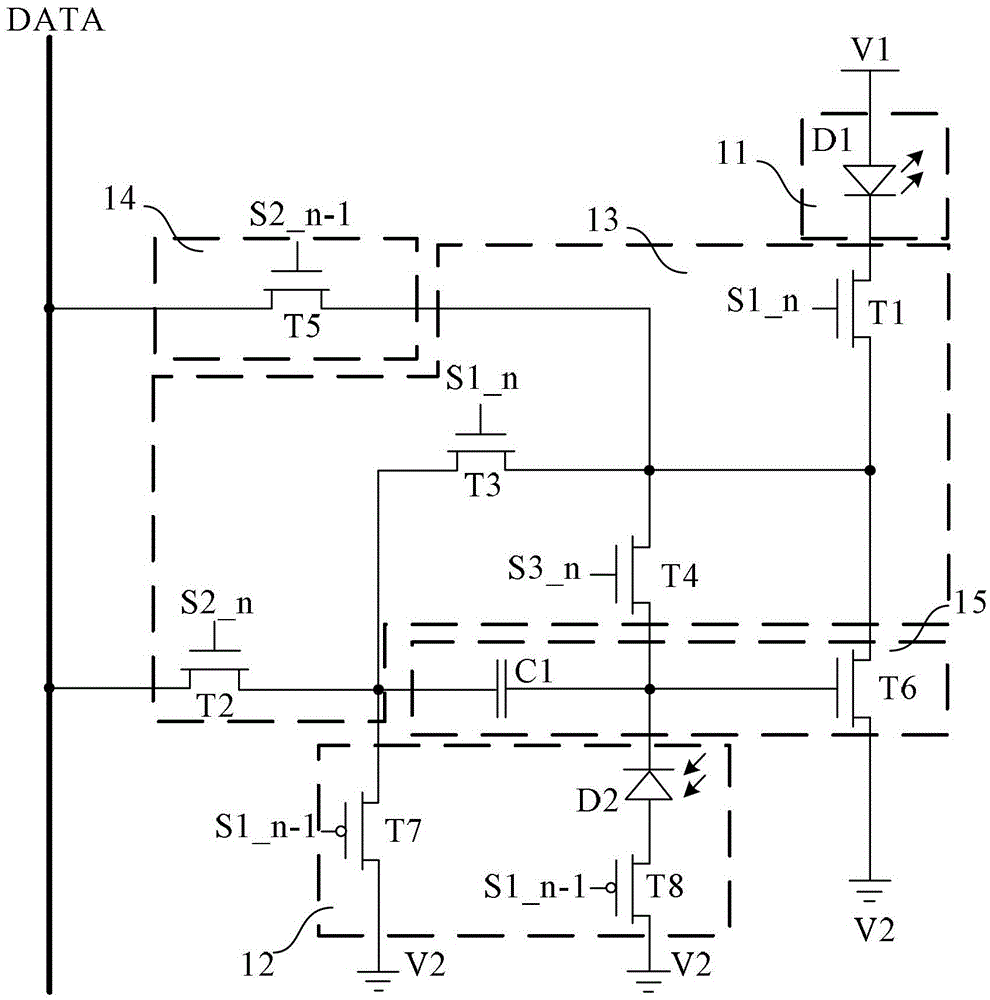

Active matrix/organic light emitting diode (AMOLED) pixel circuit, driving method thereof and display device

ActiveCN103310734AHighly integratedQuality improvementStatic indicating devicesInput/output processes for data processingActive matrixDisplay device

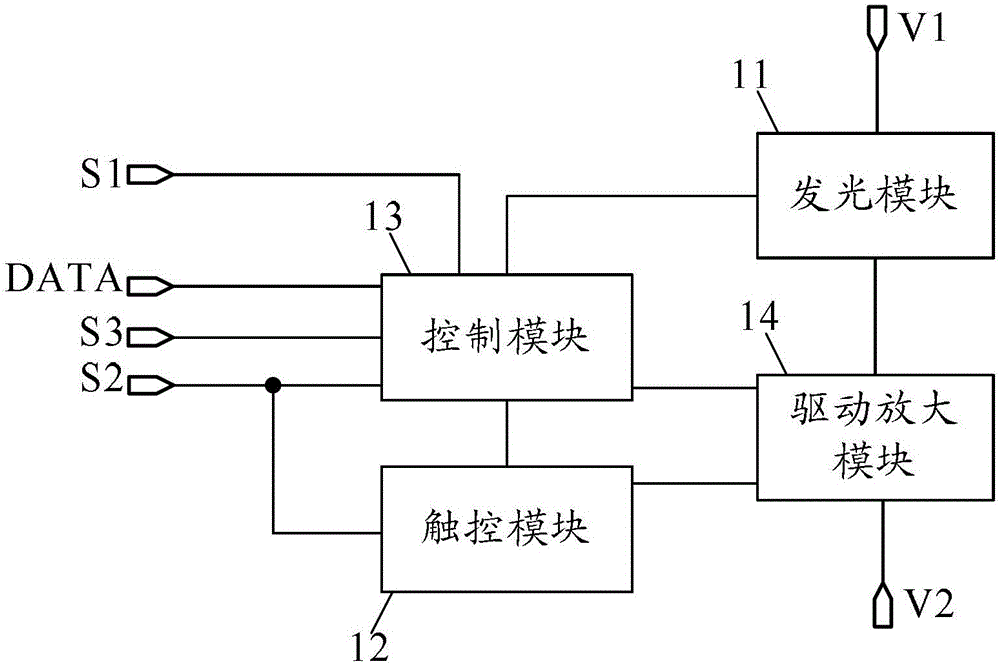

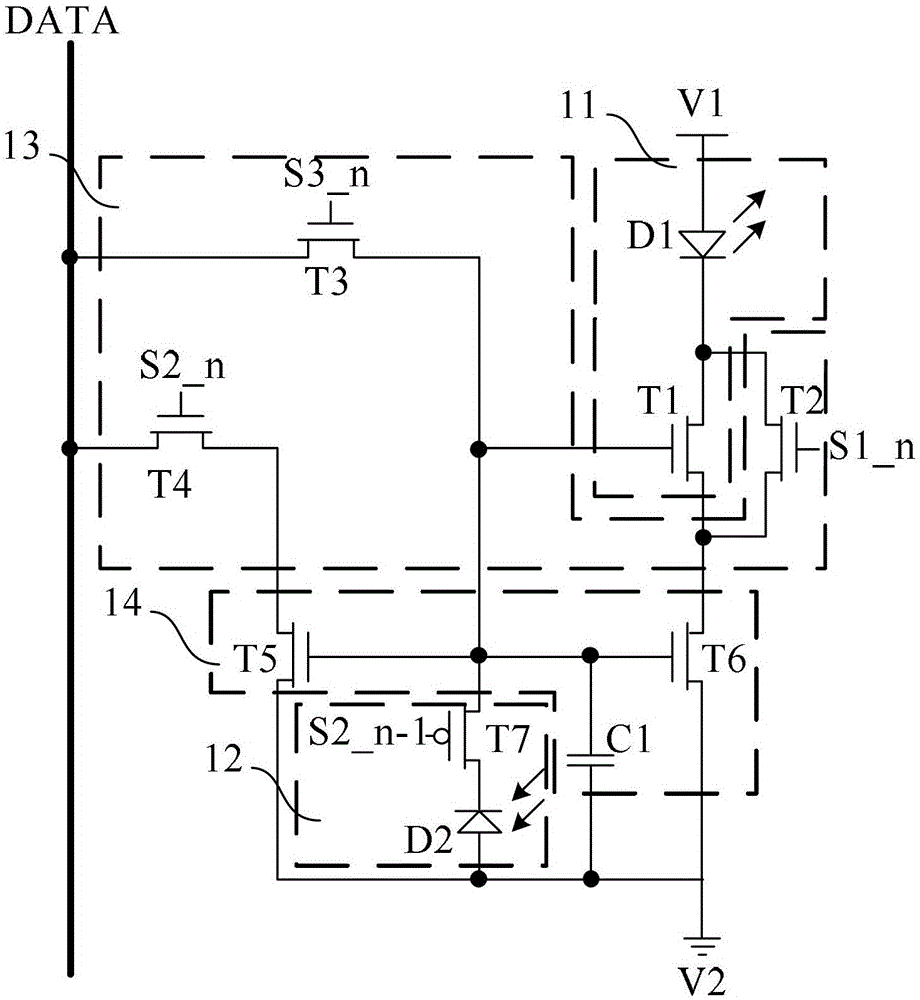

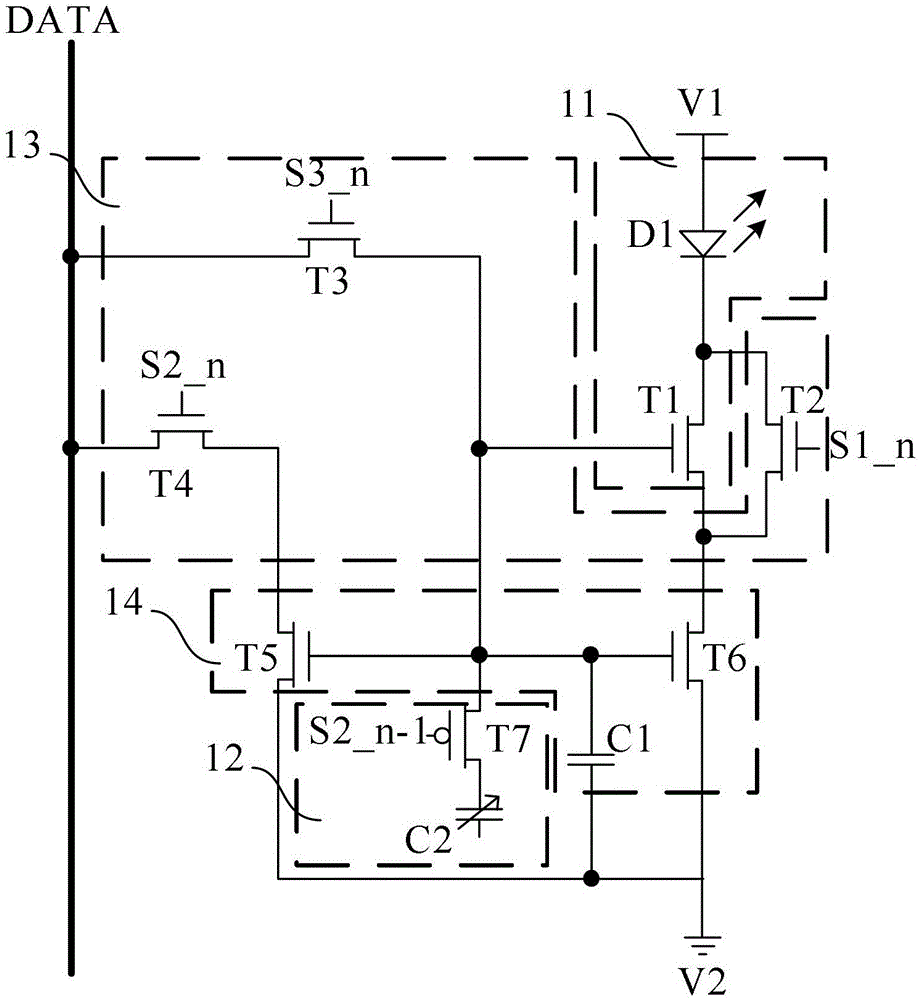

The invention discloses an active matrix / organic light emitting diode (AMOLED) pixel circuit, a driving method thereof and a display device and relates to the technical field of display. According to the AMOLED pixel circuit and the driving method of the AMOLED pixel circuit, the integration level of an AMOLED driving circuit and an embedded type touch circuit can be improved. The AMOLED pixel circuit comprises a light-emitting module, a touch module, a control module and a driving amplification module. The AMOLED pixel circuit and the driving method of the AMOLED pixel circuit are used for manufacturing the AMOLED display device.

Owner:BOE TECH GRP CO LTD +1

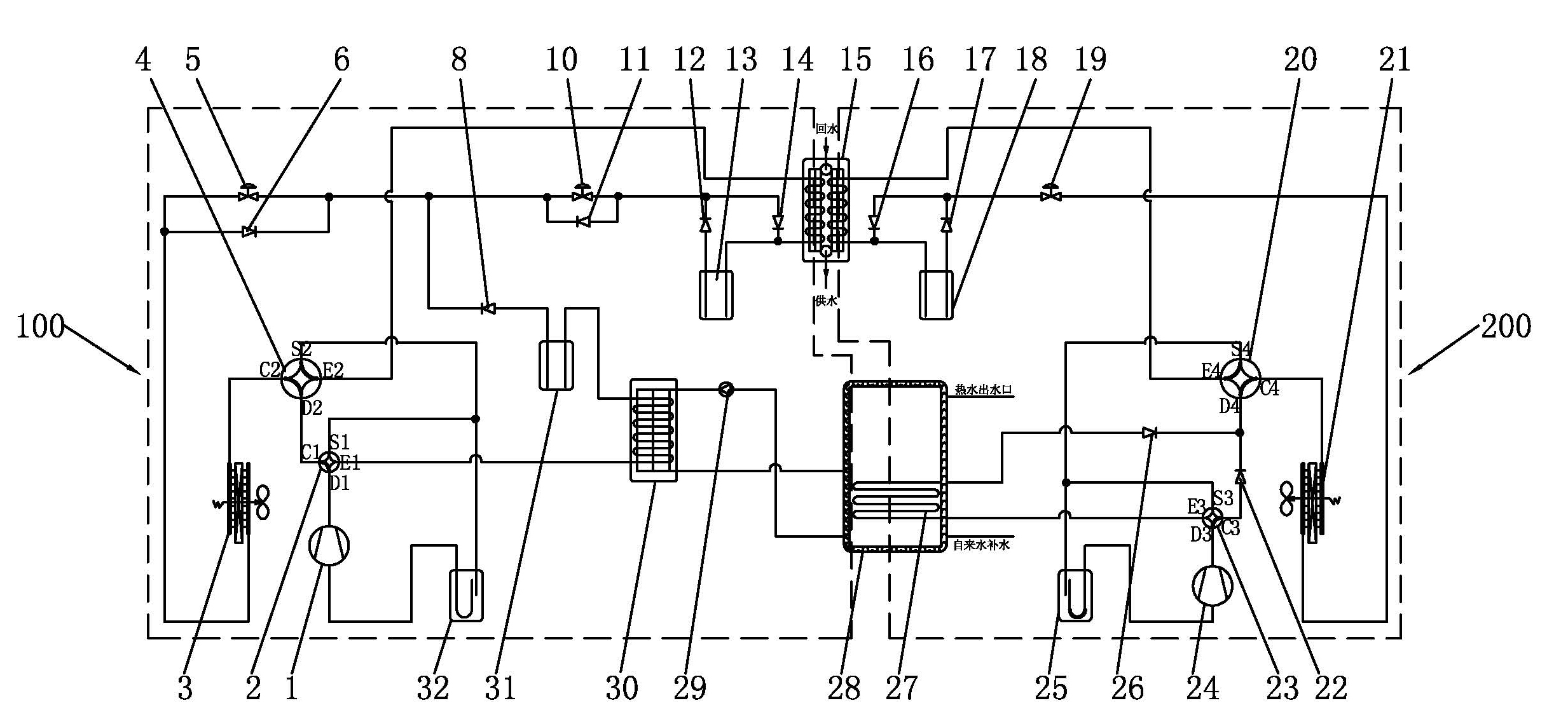

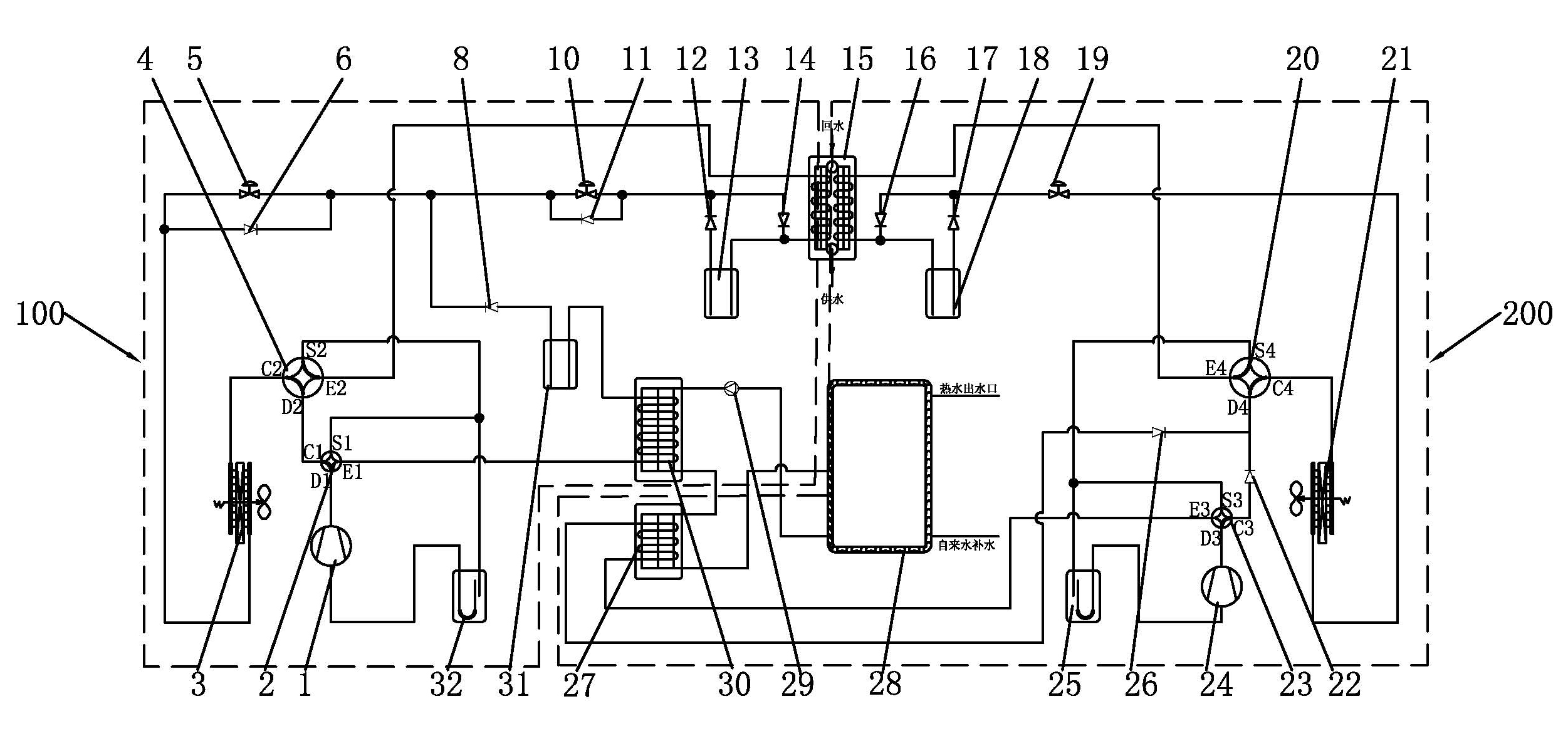

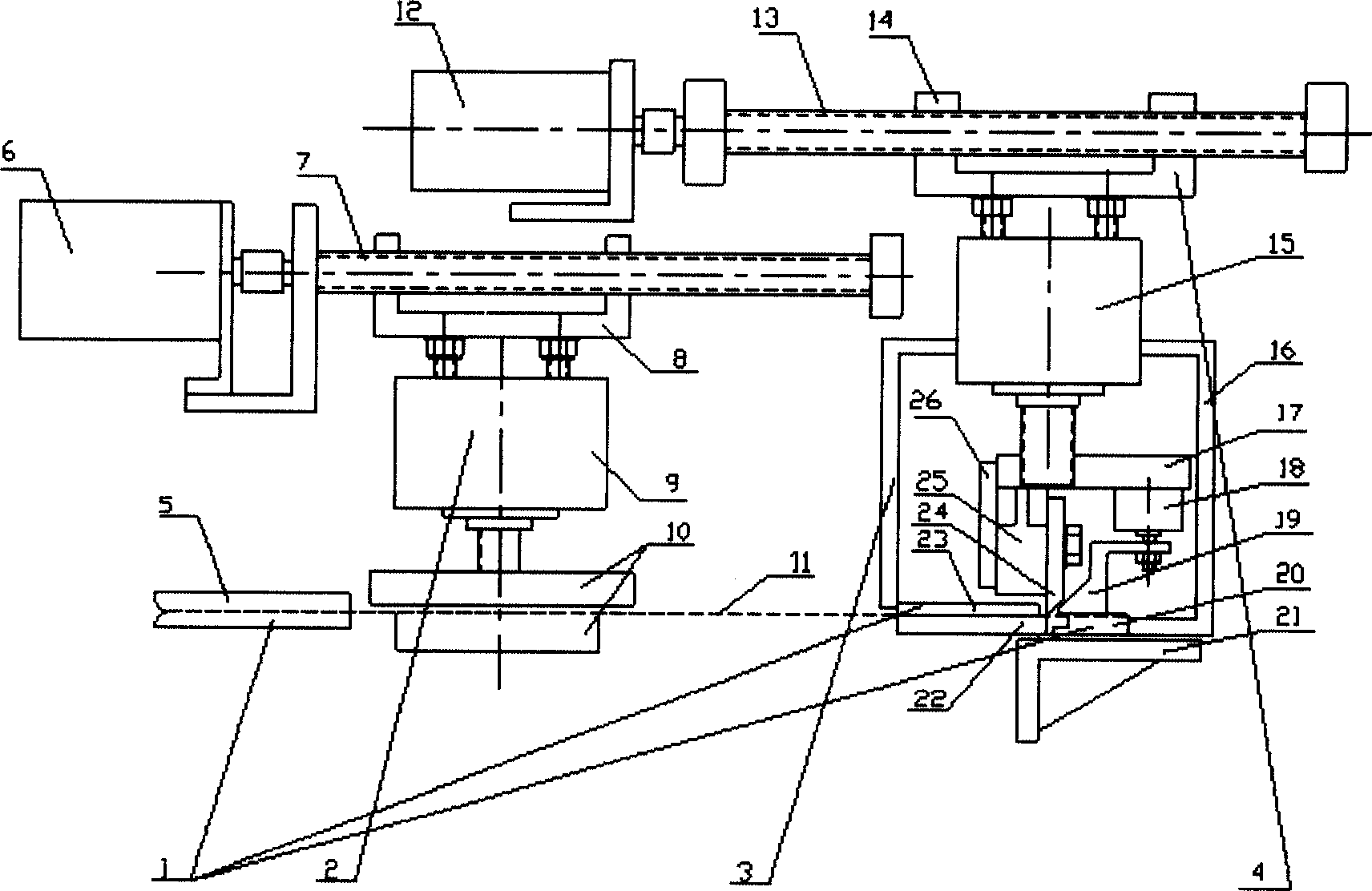

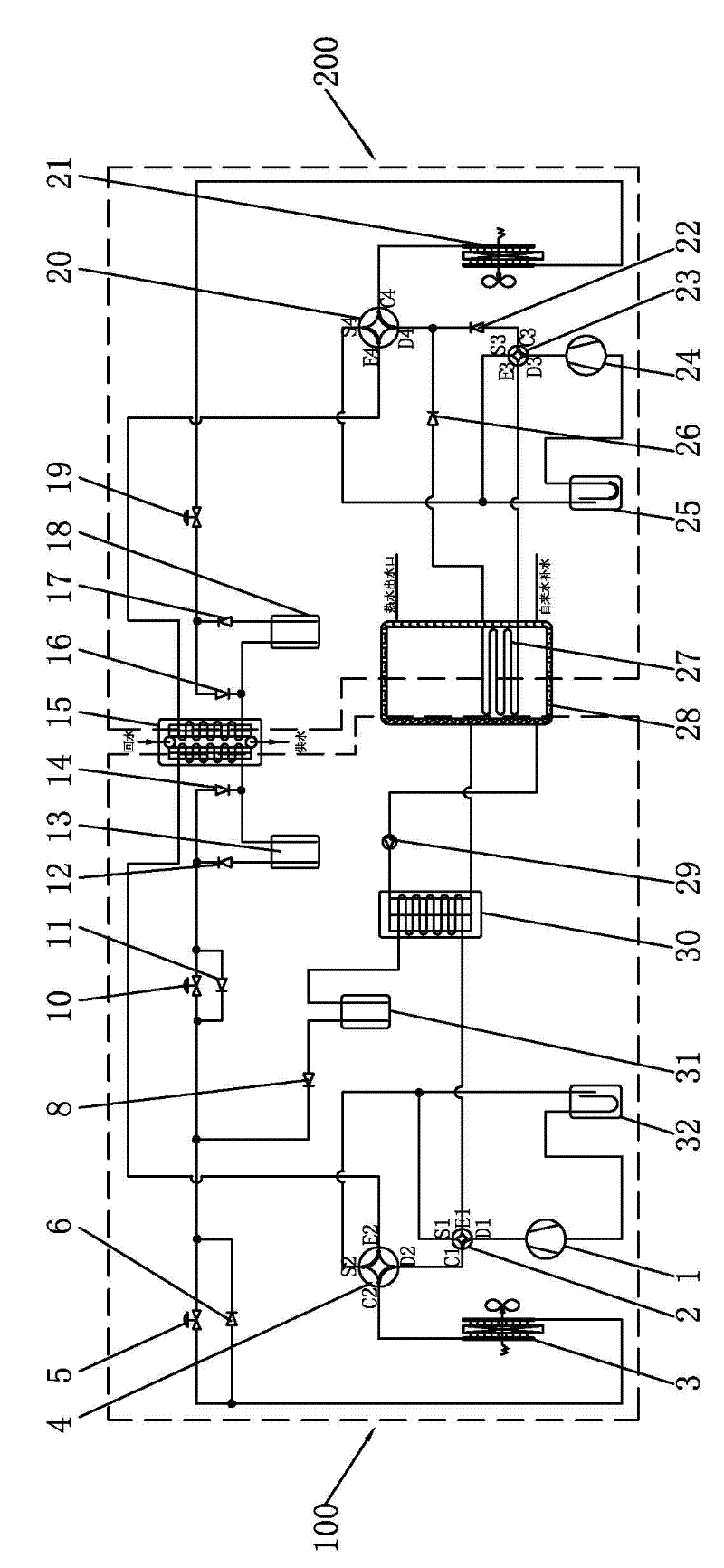

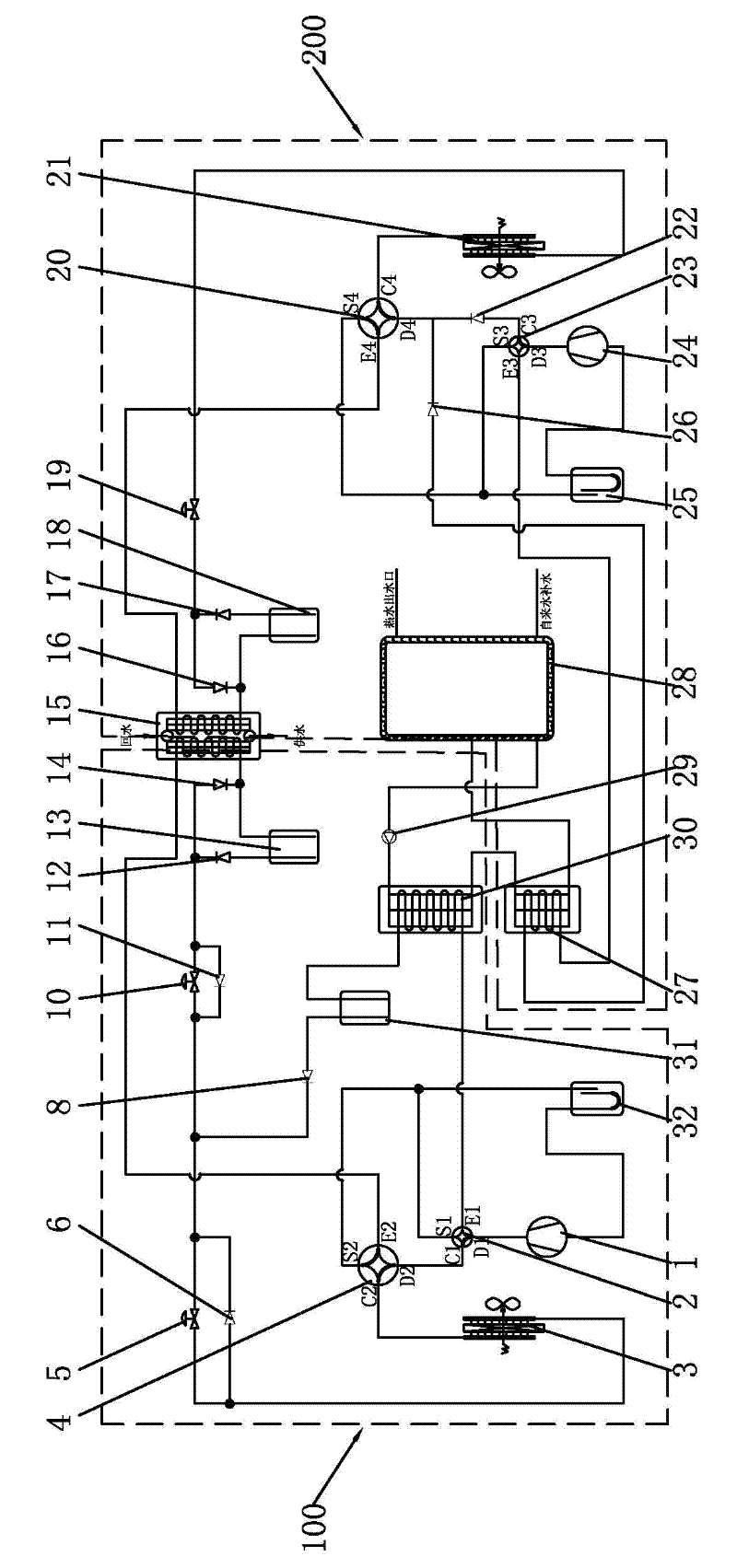

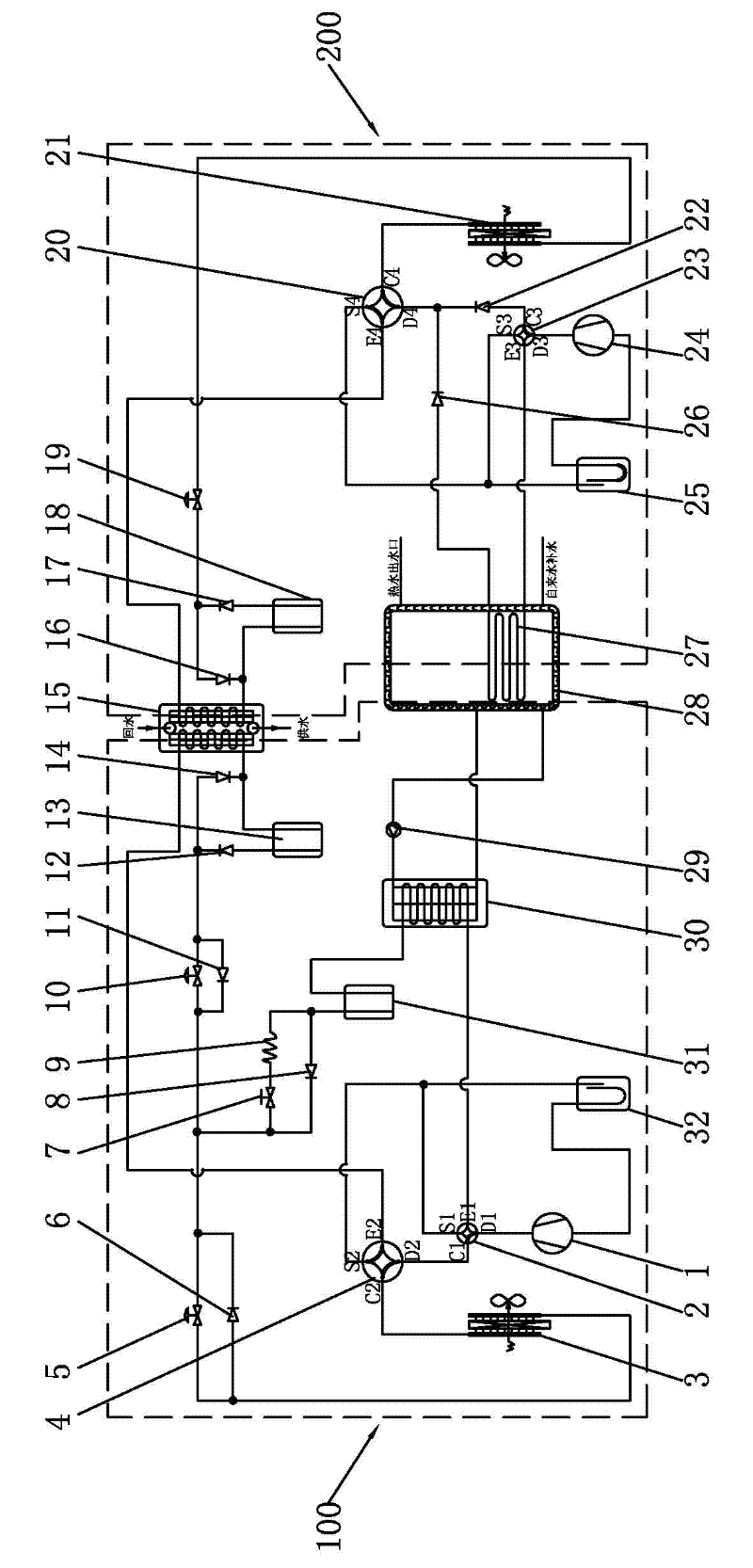

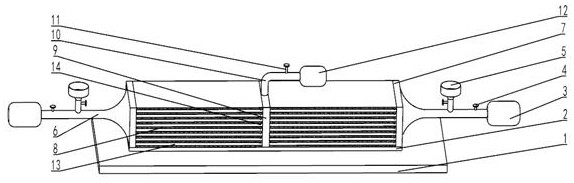

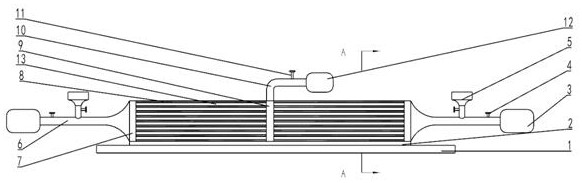

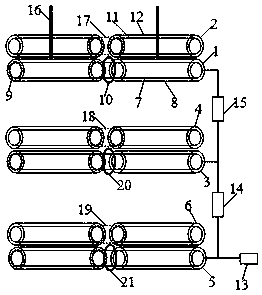

Heat recovery type air cooling heat pump unit

ActiveCN102022858AGuaranteed recyclingImprove efficiencyEnergy recovery in ventilation and heatingHeat recovery systemsRefrigerantHeat conservation

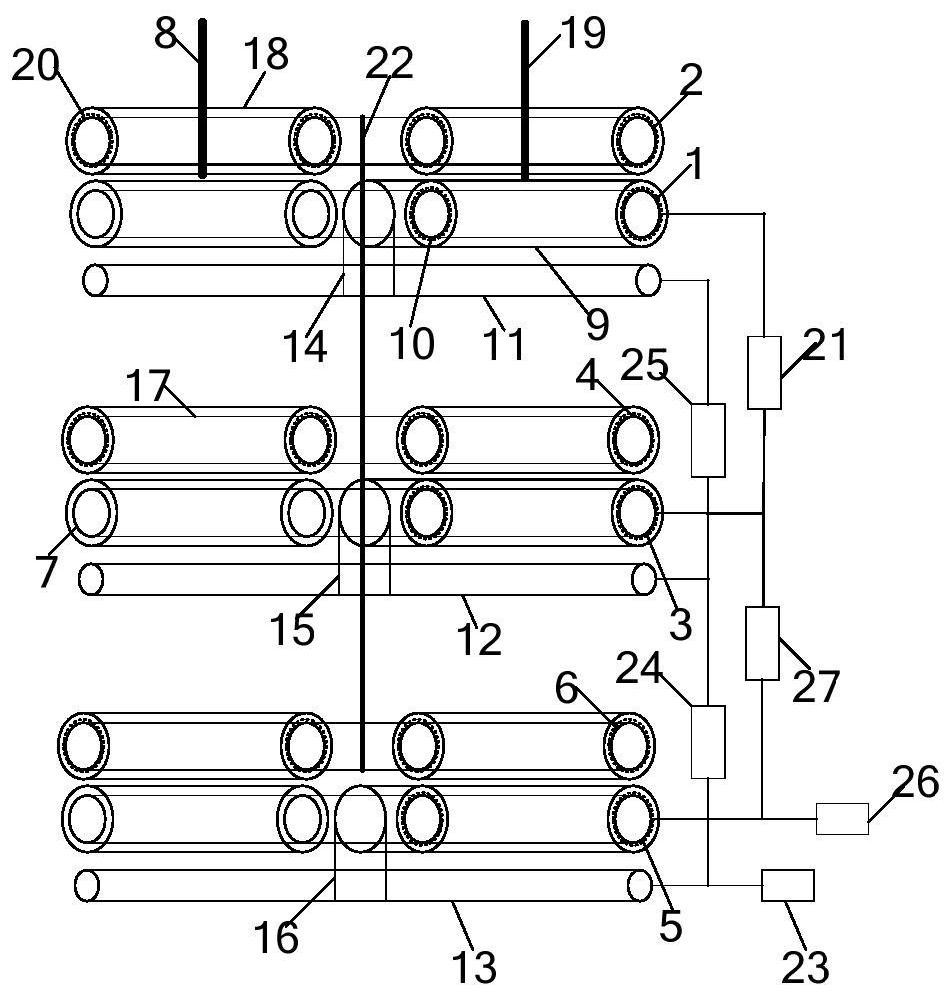

The invention discloses a heat recovery type air cooling heat pump unit comprising a first refrigerant circulating system and a second refrigerant circulating system, wherein the first refrigerant circulating system comprises a first compressor, a first four-way valve, a second four-way valve, a first air side fin type heat exchanger, an air conditioner side heat exchanger, a first air-liquid separator, a total heat recovery heat exchanger, a hot water circulating water pump, a heat preservation water tank and a valve; the second refrigerant circulating system comprises a second compressor, a third four-way valve, a fourth four-way valve, a second air side fin type heat exchanger, an air conditioner side heat exchanger, a third reservoir, a second air-liquid separator, a partial heat recovery heat exchanger, a heat preservation water tank and a valve. According the invention, heat is ensured to be effectively recovered and reused, and environment is protected from thermal pollution, thereby being environmental friendly and saving energy. In addition, the defects that air conditioner heating and daily hot water supply can not be carried out simultaneously, and the traditional total heat recovery air conditioner system which only has a single heat recovery system can not produce higher-temperature daily hot water at low temperature in winter can be effectively overcome.

Owner:GUANGDONG EUROKLIMAT AIR CONDITIONING & REFRIGERATION

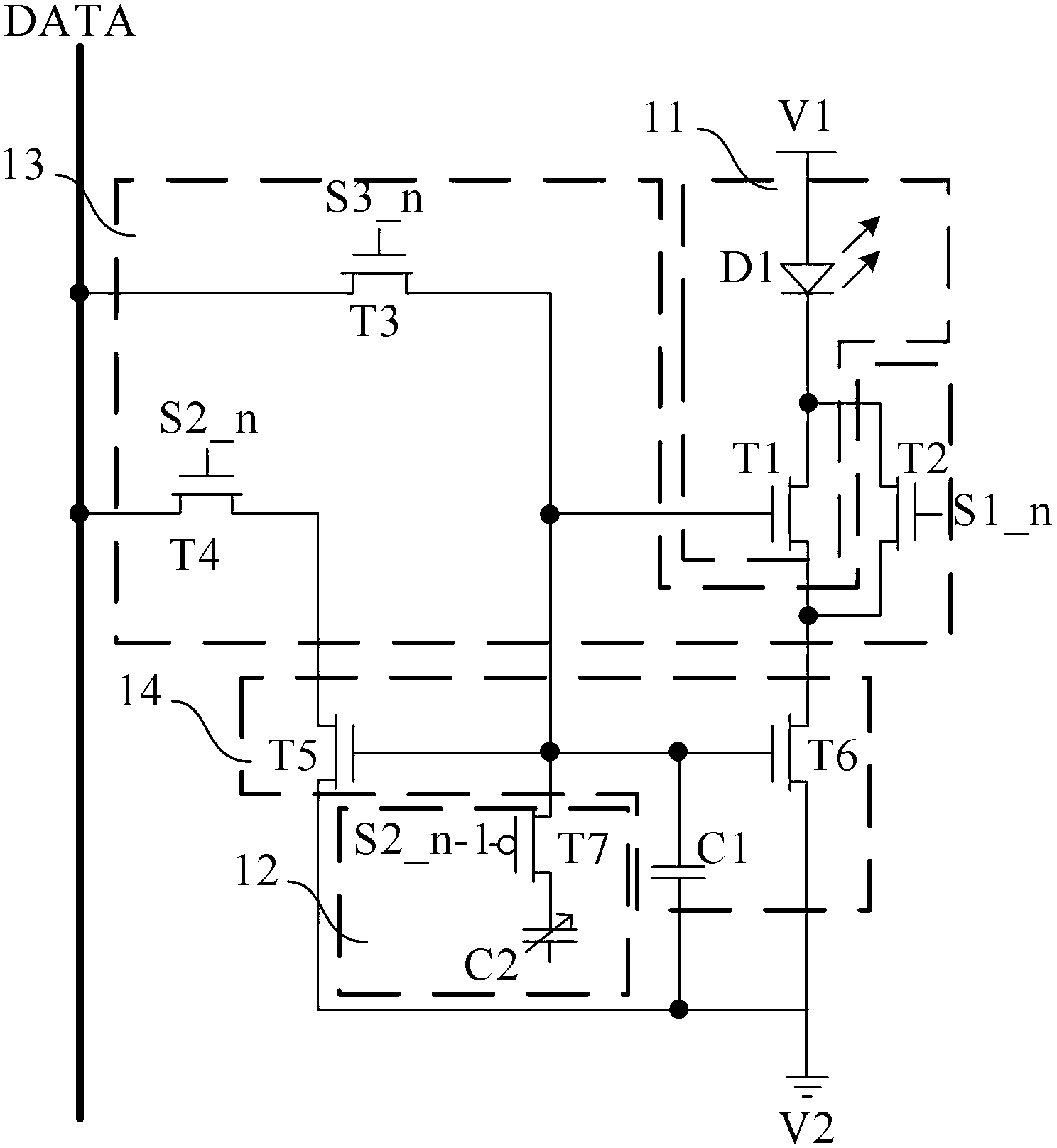

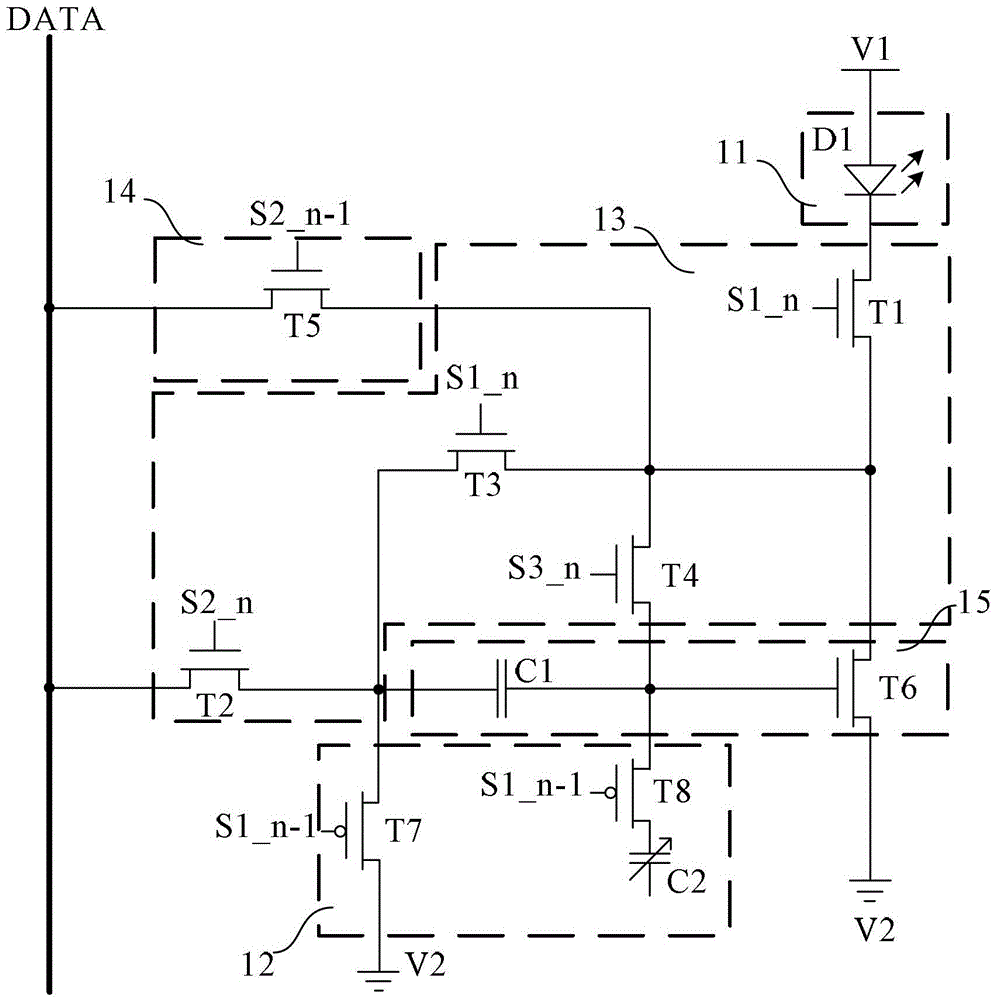

AMOLED pixel circuit and driving method and display device thereof

ActiveCN103345901AHighly integratedQuality improvementStatic indicating devicesInput/output processes for data processingDisplay deviceEmbedded system

The invention discloses an AMOLED pixel circuit and a driving method and a display device thereof, and relates to the technical field of displaying. The integration degree of an embedded type touch circuit and an AMOLED driving circuit can be improved. The AMOLED pixel circuit comprises a light-emitting module, a touch module, a control module and a driving amplifying module. The AMOLED display device can be well manufactured.

Owner:BOE TECH GRP CO LTD +1

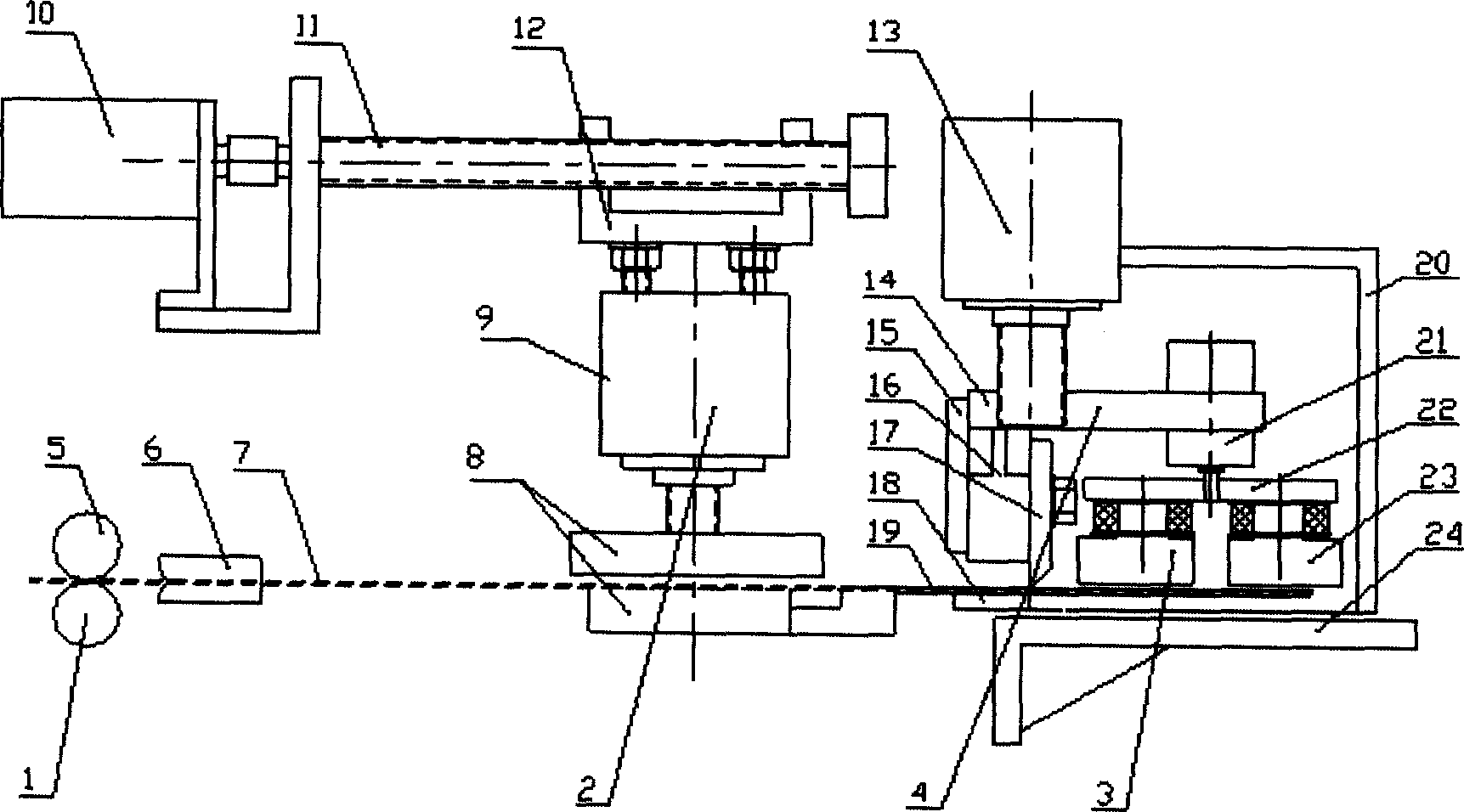

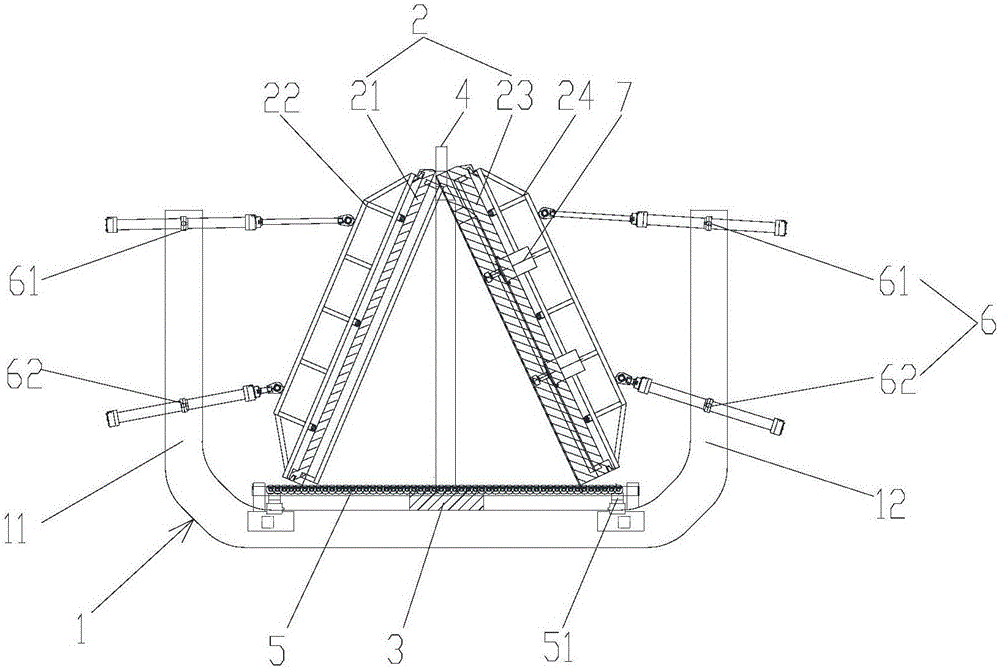

Feeding cutting and pressing binding device of flexible iron base thin belt material

InactiveCN1718365ARealize transferSimultaneous productionMetal-working feeding devicesOther manufacturing equipments/toolsBand shapeEngineering

A feeding, shearing and sticking machine for the flexible Fe-base thin band used for anti forge metallic labels is composed of a band shaping unit, a band piloting and feeding unit consisting of piloting plate, clamping plate, clamping cylinder, motor, etc, an electromagnetic sucking-transferring unit consisting of DC electromagnet and sucking plate, and a shearing-sticking unit consisting of shearing cylinder, shearing blade, lower sheering edge sticking cylinder, etc.

Owner:SHANGHAI JIAO TONG UNIV

Continuous shearing and pressing device for rigid thin band

InactiveCN1730213ASimultaneous productionImprove continuityMetal-working feeding devicesLaminationAnti theftEngineering

The invention relates to a stiff thin tape continuous shearing and press-plaster device in mechatronics domain, which comprises tape-guiding parts, tape-pinching parts, tape shearing and press-plaster parts and shifting parts. Tape-guiding parts comprise guide runner, material-leading grid and striker grid; tape-pinching parts comprise pinch-off blades, clamping cylinder, actuating motor running gear and slider of pinching parts; tape-pinching parts comprise shearing cylinder, scissors and so on; shifting parts comprise driving motor, running gear and slider. The invention improves productive efficiency and can be used in automated producing equipment of metal anti-theft label.

Owner:SHANGHAI JIAO TONG UNIV

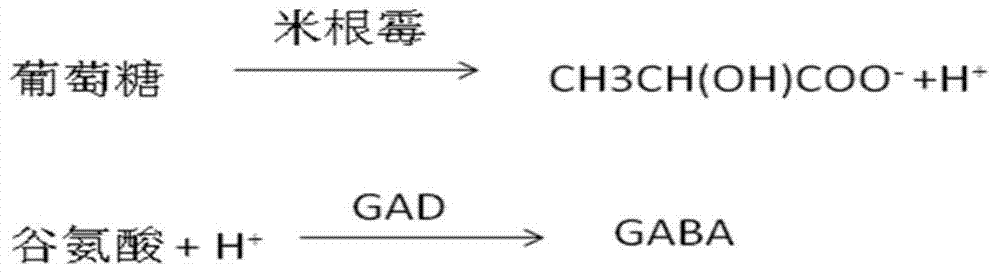

Method for producing lactic acid and simultaneously realizing coupling preparation of GABA (gamma-aminobutyric acid)

The invention discloses a method for producing lactic acid and simultaneously realizing coupling preparation of GABA (gamma-aminobutyric acid). The method comprises the steps of inoculating rhizopus oryzae into a fermentation culture medium to perform fermentation, adding glutamic acid decarboxylase, pyridoxal phosphate and L-sodium glutamate into a fermentation solution when the pH value of the fermentation solution is less than 4.8, then continuously adding L-sodium glutamate into the fermentation solution, and generating GABA of glutamic acid decarboxylase by utilizing the vitality of catalyzing glutamic acid to consume H+ in an environment so as to maintain the pH value of the fermentation solution at 4.8-6.0 and achieve the purposes of relieving acid inhibition against fermentation of lactic acid and realizing simultaneous production of lactic acid and GABA. The invention provides a new method for relieving the inhibition of a substrate for fermentation of lactic acid; furthermore, in the fermentation process, the coupling production of a functional compound, namely gamma-aminobutyric acid, is realized, so that the yield of lactic acid is increased, and the economy of the process is further improved.

Owner:SHANDONG YANGCHENG BIOLOGY TECH CO LTD

Process for preparing gamma-amino butyric acid through enzymatic conversion

InactiveCN1298860CImprove conversion rateIncrease reaction rateTransferasesMicroorganism based processesGlutamate decarboxylaseL-Aspartate

The invention discloses an enzyme conversion method for preparing gamma-butyric acid. The preparation method comprises employing two mixed acidic amino acids of L-glutamic acid and L-aspartic acid as raw material, mixing the cells of Escherichia.coli AS1.505 with highly active L-glutamic acid decarboxylases and the conversion liquid containing the mixture of L-glutamic acid and L-aspartic acid, implementing enzymatic reaction under the temperature of 28-45 DEG C, then separating the conversion products by isoelectric point crystallization process or isoelectric point crystallization and ion exchange resin combined method to obtain high purity gamma-butyric acid and L-aspartic acid. The invention solves the problem of the highly effective separation of two acidic mixed amino acids, and obtains gamma-butyric acid with higher additional value, and has advantages of low price, simple operation, short conversion time, and low production cost.

Owner:NANJING UNIV

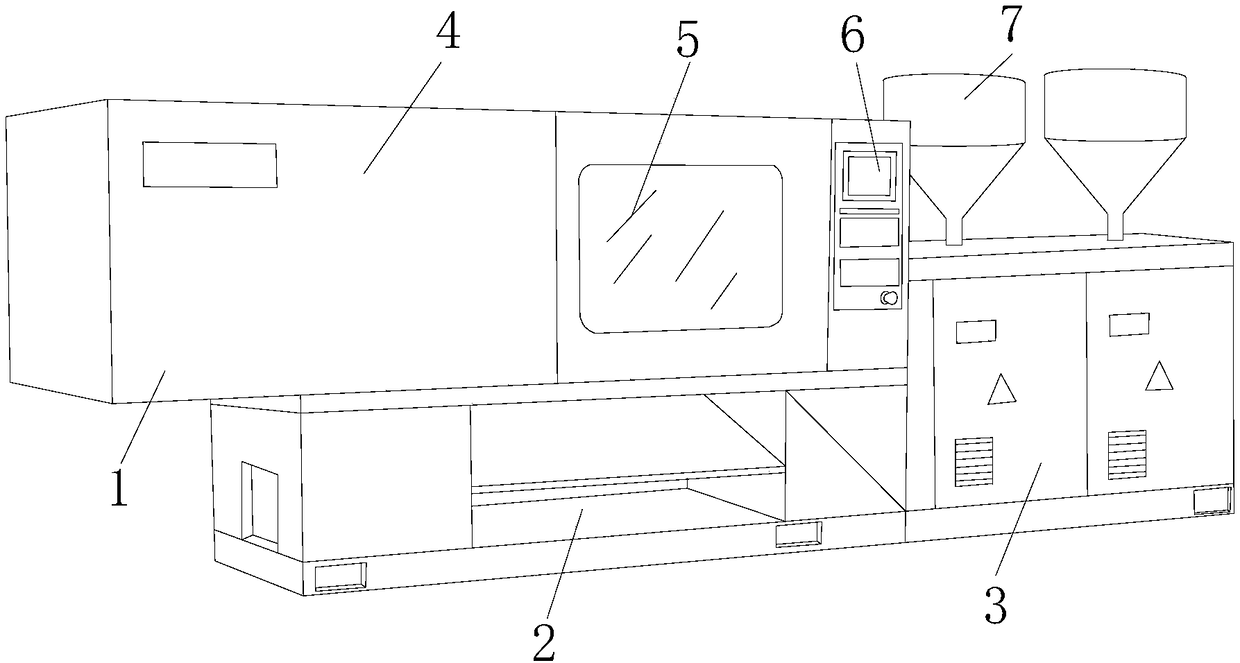

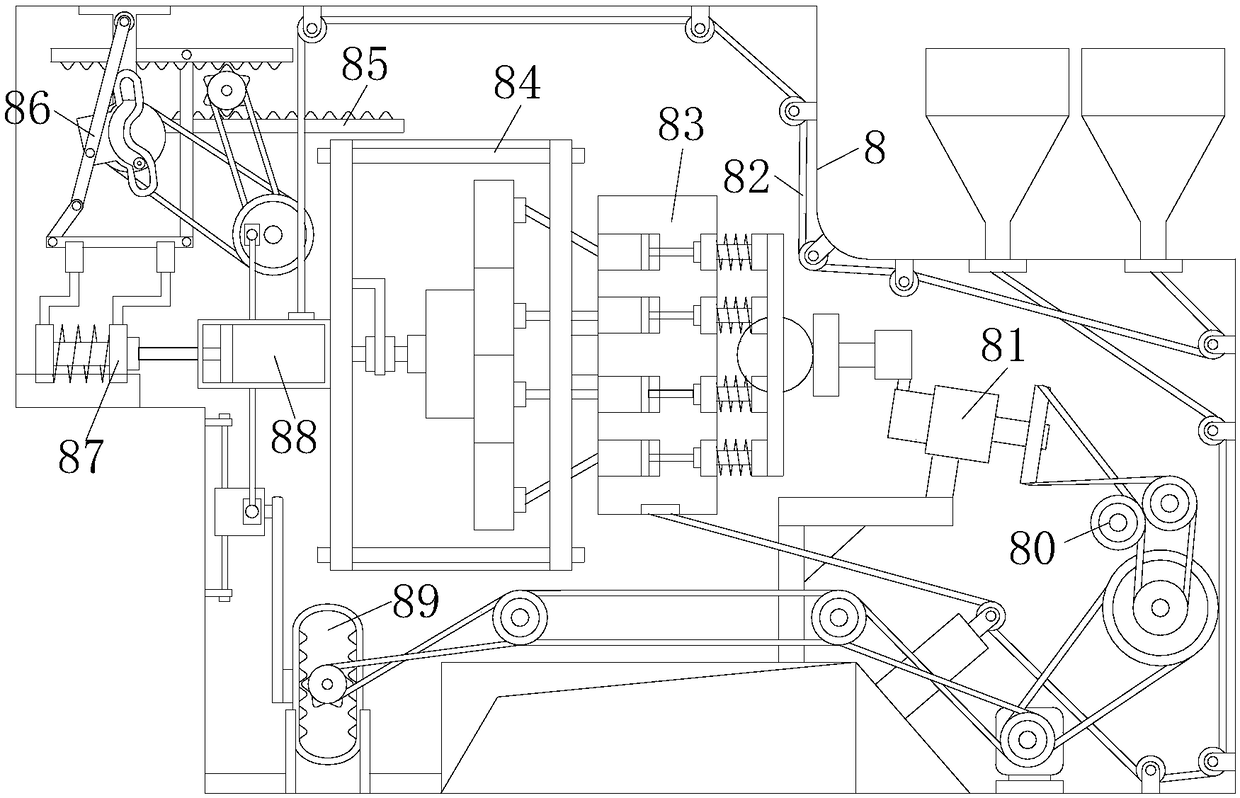

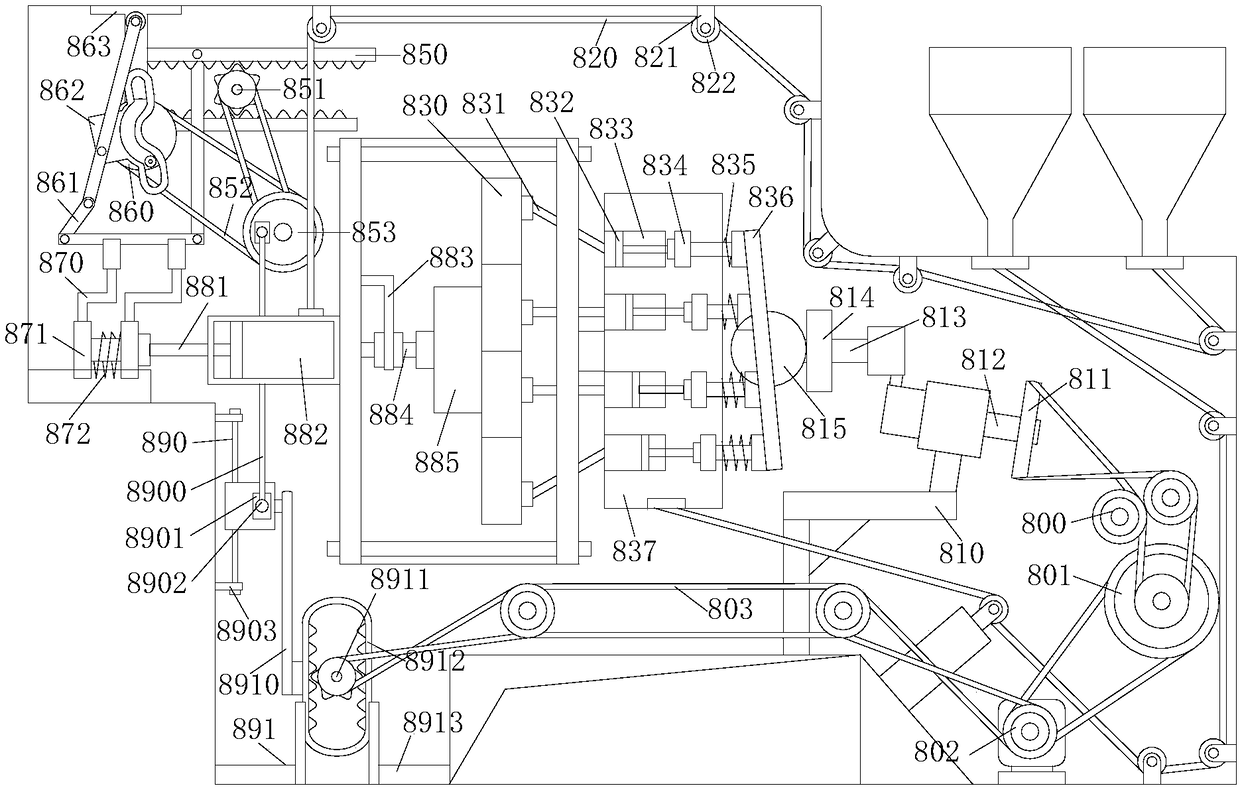

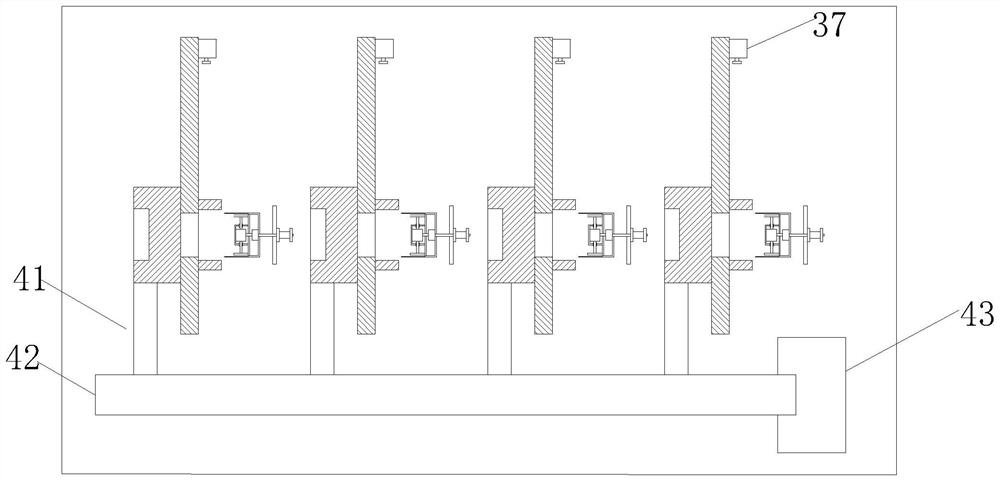

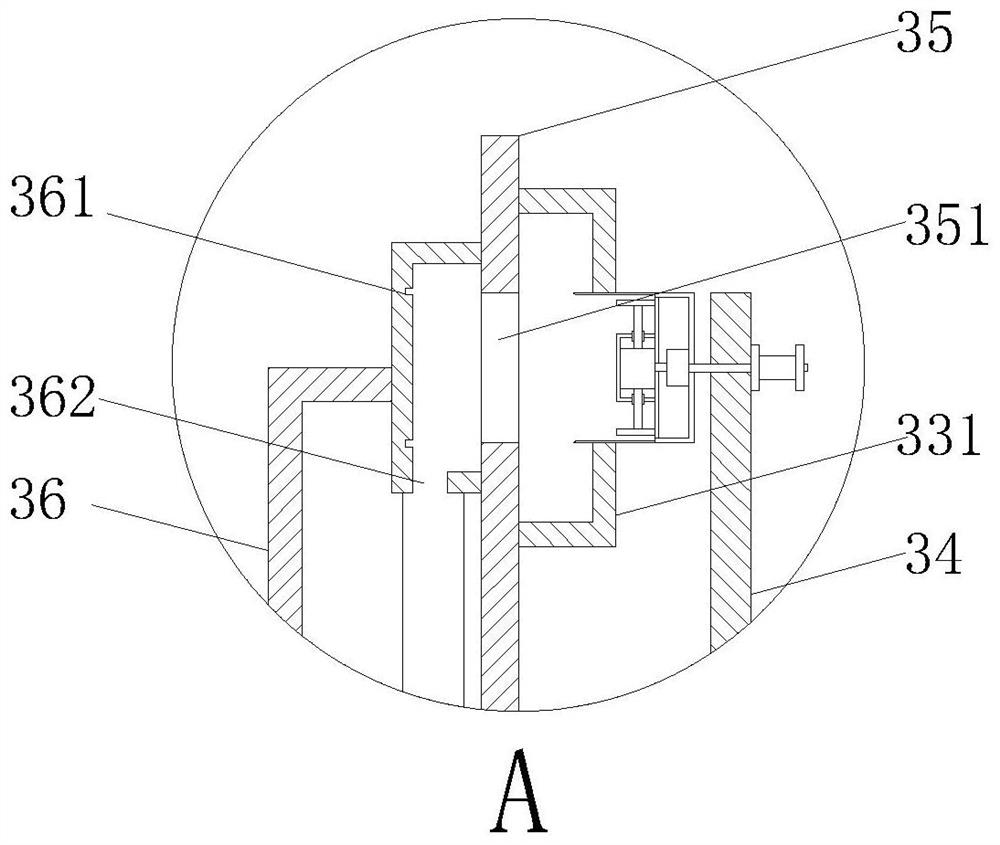

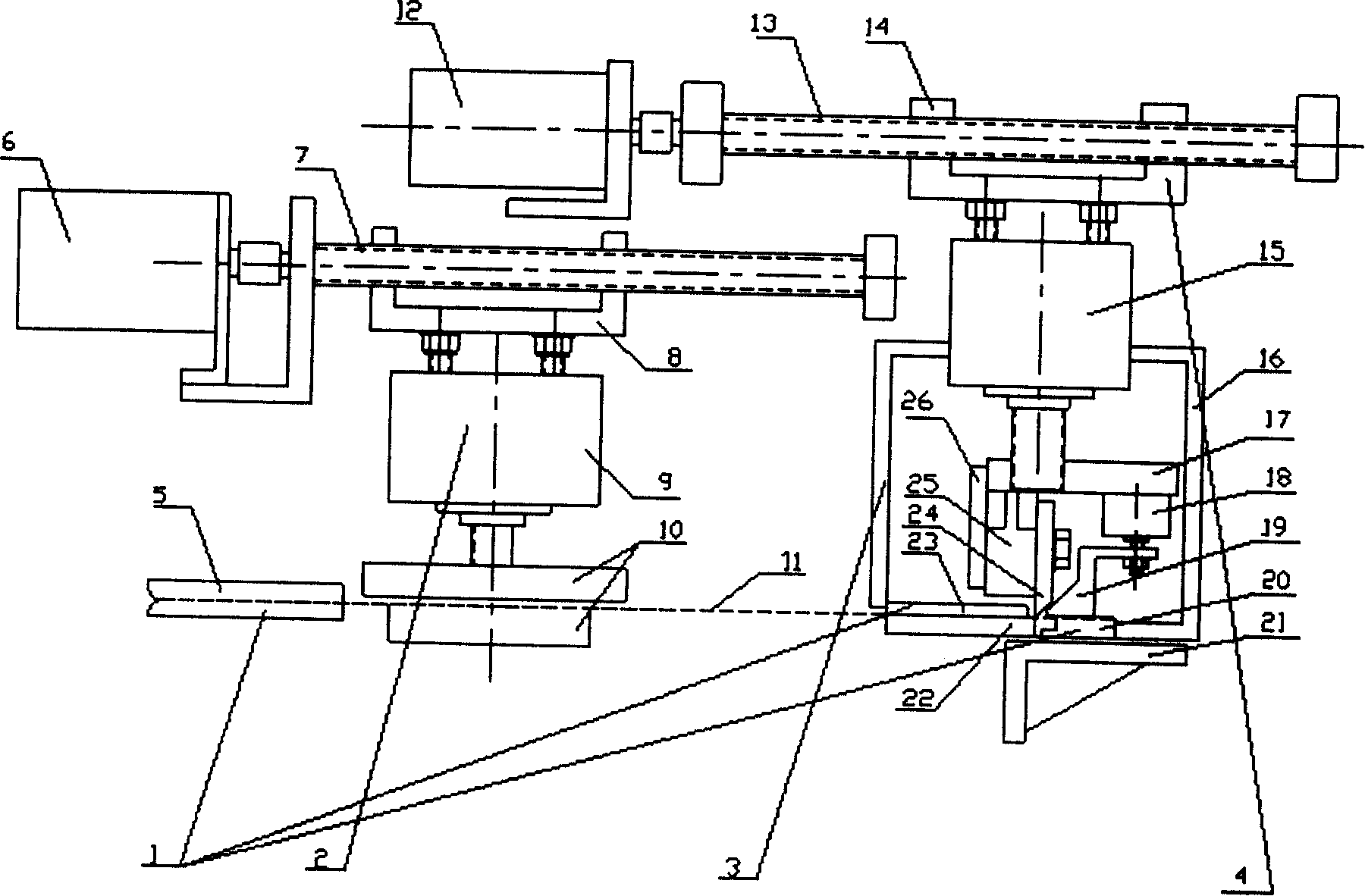

Multi-die injection molding machine

InactiveCN108381848ASimultaneous productionNo frequent replacementEngineeringInjection molding machine

The invention discloses a multi-die injection molding machine. The multi-die injection molding machine structurally comprises an injection molding machine body, feeding hoppers and an interior injection molding device. A pair of feeding hoppers are arranged and communicate with the injection molding machine body. The feeding hoppers are arranged at the right-angle structure position of the injection molding machine body. The interior injection molding device is arranged in the injection molding machine body. The feeding hoppers penetrate the injection molding machine body and communicate withthe interior injection molding device. The injection molding machine body is composed of an integrated frame bin, a maintaining box, an integral machine frame, a visual machine frame and an intelligent control board. A motor rotates to drive rotation of a belt wheel transmission mechanism and an inner meshing reciprocated transmission mechanism, accordingly, the multi-die injection molding machineis driven to conduct multi-die production, a single-die injection molding device is driven to conduct single-die production, and accordingly simultaneous production of different specifications of plastic products is achieved; and frequent die replacement is not needed, and the plastic product manufacturing efficiency is greatly improved.

Owner:柴建华

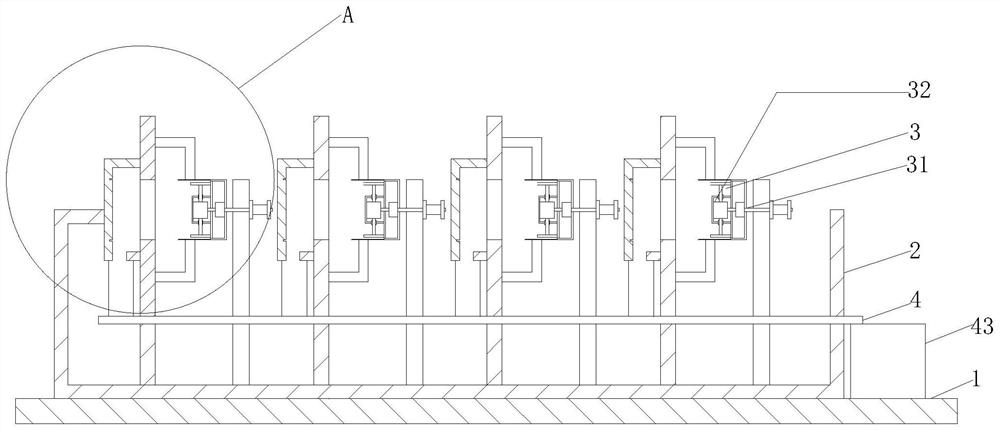

A kind of copper clad laminate die-cutting processing equipment and die-cutting processing technology

ActiveCN112077937BPrecise cuttingIncrease production capacityMetal working apparatusCircuit precursor manufactureMachine buildingIndustrial engineering

The invention provides a copper clad laminate die-cutting processing equipment and die-cutting processing technology, which relate to the field of mechanical manufacturing and processing, including a bottom plate, a support frame, a die-cutting device and a collecting device. production capacity, and at the same time, it can position the copper clad laminate to ensure the accuracy of the die cutting process of the copper clad laminate, avoid the offset of the copper clad laminate, and can automatically repair after the die cutting process, without secondary processing, which improves the product quality. production efficiency.

Owner:乐清市金泰铜业有限公司

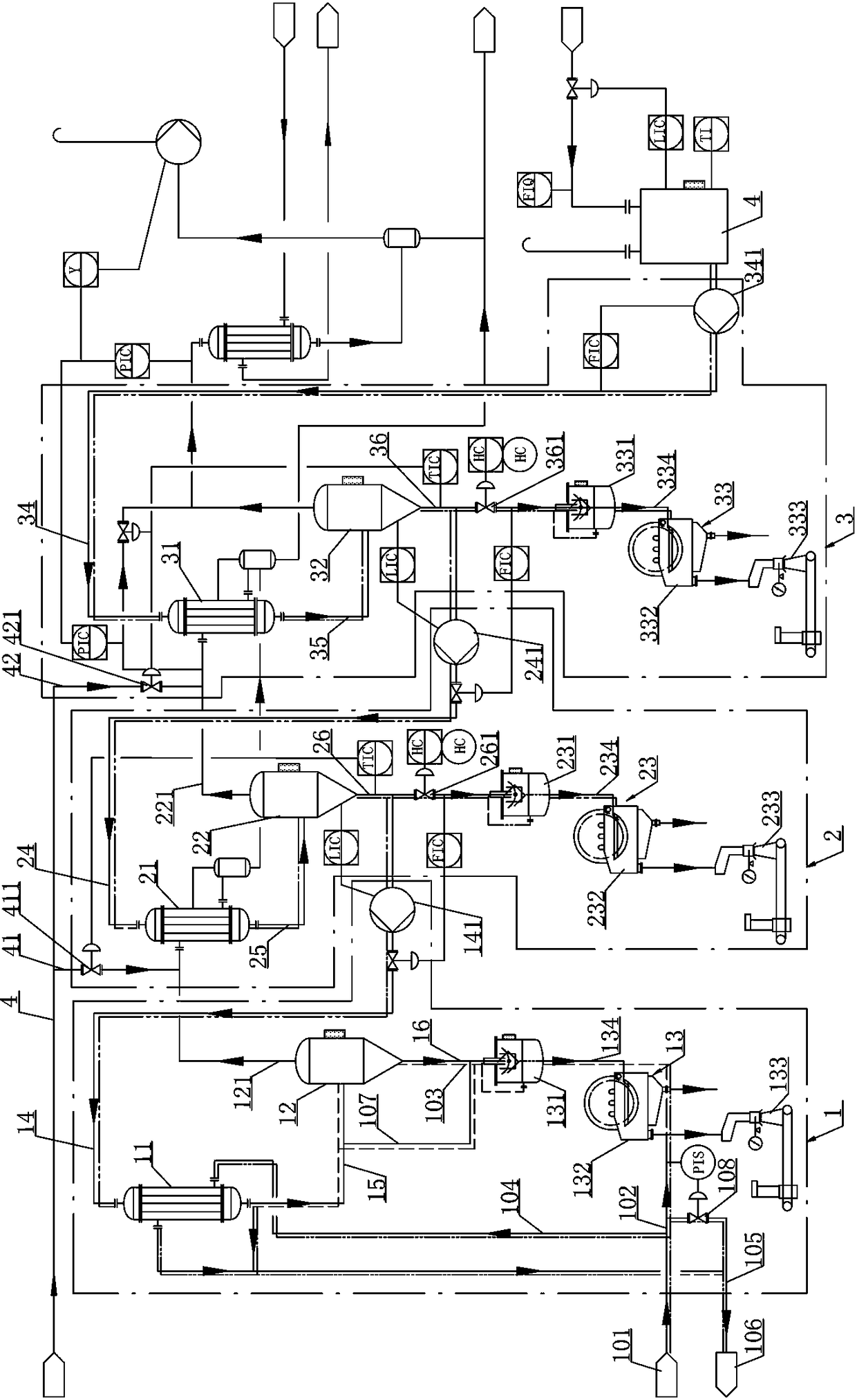

Alkali concentrated flake device capable of simultaneously producing different concentrations of solid caustic soda

PendingCN108328626ASimultaneous productionIncrease flexibilityAlkali metal oxides/hydroxidesEnergy consumptionTriple effect

The invention discloses an alkali concentrated flake device capable of simultaneously producing different concentrations of solid caustic soda. The alkali concentrated flake device comprises an alkaliliquor trough, a triple-effect concentrated flake mechanism, a quadratic-effect concentrated flake mechanism and one-effect concentrated flake mechanism, wherein each one-effect concentrated flake mechanism comprises an evaporator, a separator and a flaking mechanism, a feeding pipe of the evaporator in the quadratic-effect concentrated flake mechanism is communicated with an output pipe on a separator material outlet in the triple-effect concentrated flake mechanism, and a feeding pipe of the evaporator in the one-effect concentrated flake mechanism is communicated with an output pipe on a separator material outlet in the quadratic-effect concentrated flake mechanism. The alkali concentrated flake device has the advantages that the flexibility is high, one type of caustic soda flakes ofany concentration in the range of 50 to 99 percent can be produced according to the customer requirement, various caustic soda flakes of different concentrations can be simultaneously produced, so that one set of device can perform the diversified production according to different requirements of the customer, thereby greatly improving the market competence of solid caustic soda production enterprises, and also effectively reducing the production energy consumption.

Owner:苏州天沃环境能源工程有限公司

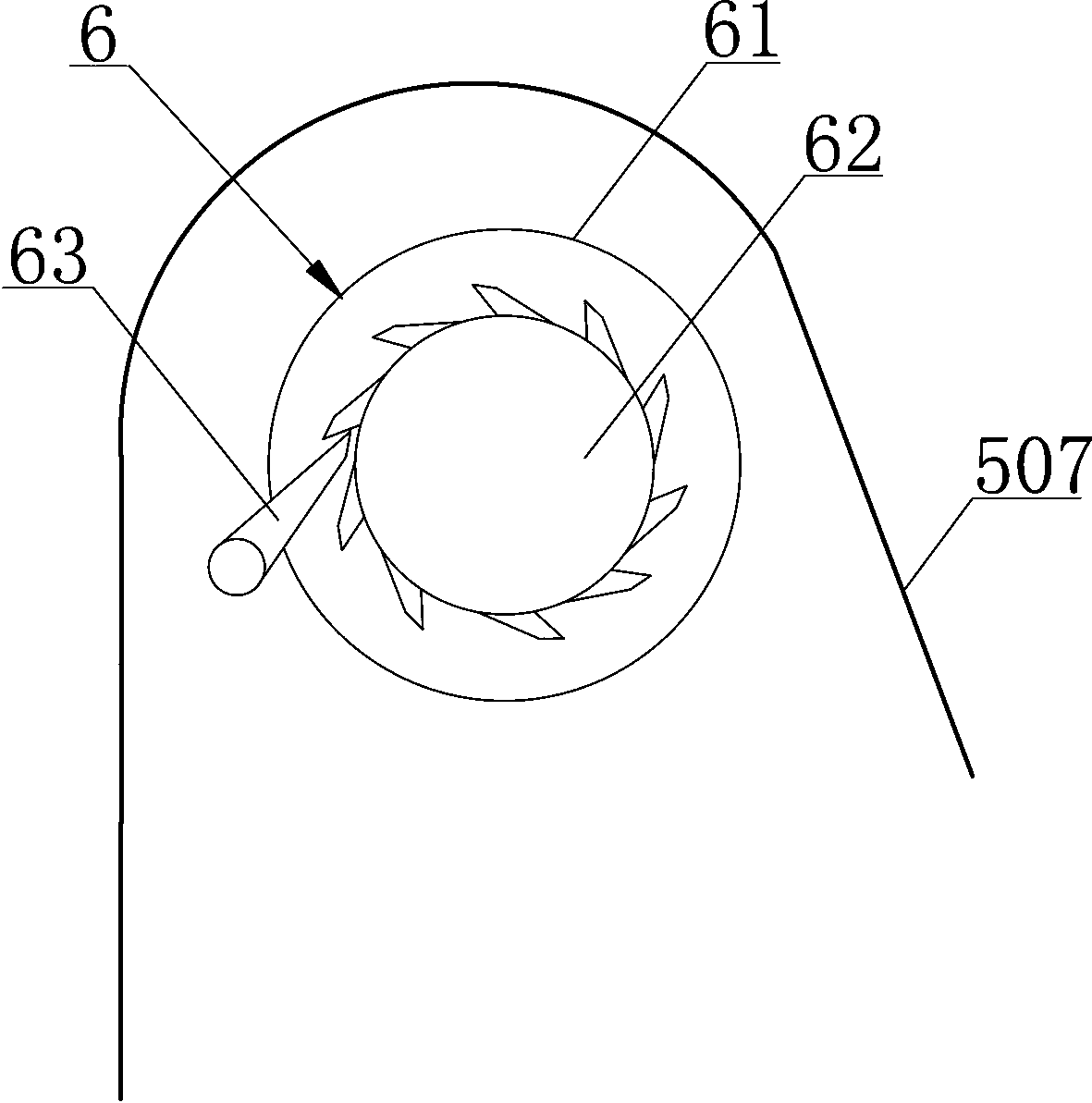

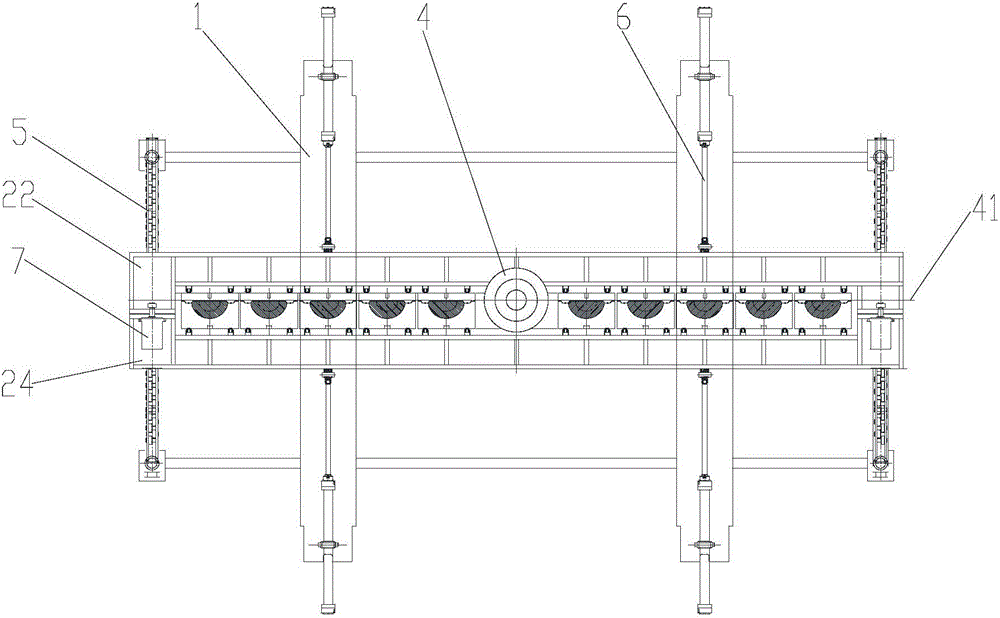

Automotive glass guide slot extrusion and spraying all-in-one machine

PendingCN107961925AIncrease productivityIncrease flexibilitySpraying apparatusDomestic articlesEngineeringMechanical engineering

The invention provides an automotive glass guide slot extrusion and spraying all-in-one machine. The automotive glass guide slot extrusion and spraying all-in-one machine comprises an extruder and a spraying device. The spraying device comprises a base. A pair of supporting frame slide slots are formed in the base. Two sides of the supporting frame slide slots are each provided with a spraying assembly slide slot parallel with the supporting frame slide slots. A plurality of supporting frame assemblies are arranged on the supporting frame slide slots in a sliding mode. A plurality of sprayingassemblies are arranged on the spraying assembly slide slots in a sliding mode. The supporting frame assemblies and the spraying assemblies can all slide on the base, the interval between every two adjacent supporting frame assemblies or the interval between every two adjacent spraying assemblies can be freely adjusted according to actual needs, the flexibility of the whole equipment is much higher, the distance between supporting plates can be flexibly adjusted when different specifications of glass guide slots are sprayed, and the spraying position and spraying angle of a spraying head can be freely adjusted within the rotation range of a supporting arm. By means of the automotive glass guide slot extrusion and spraying all-in-one machine, the spraying efficiency of the glass guide slotsis improved.

Owner:重庆米纳橡塑有限公司

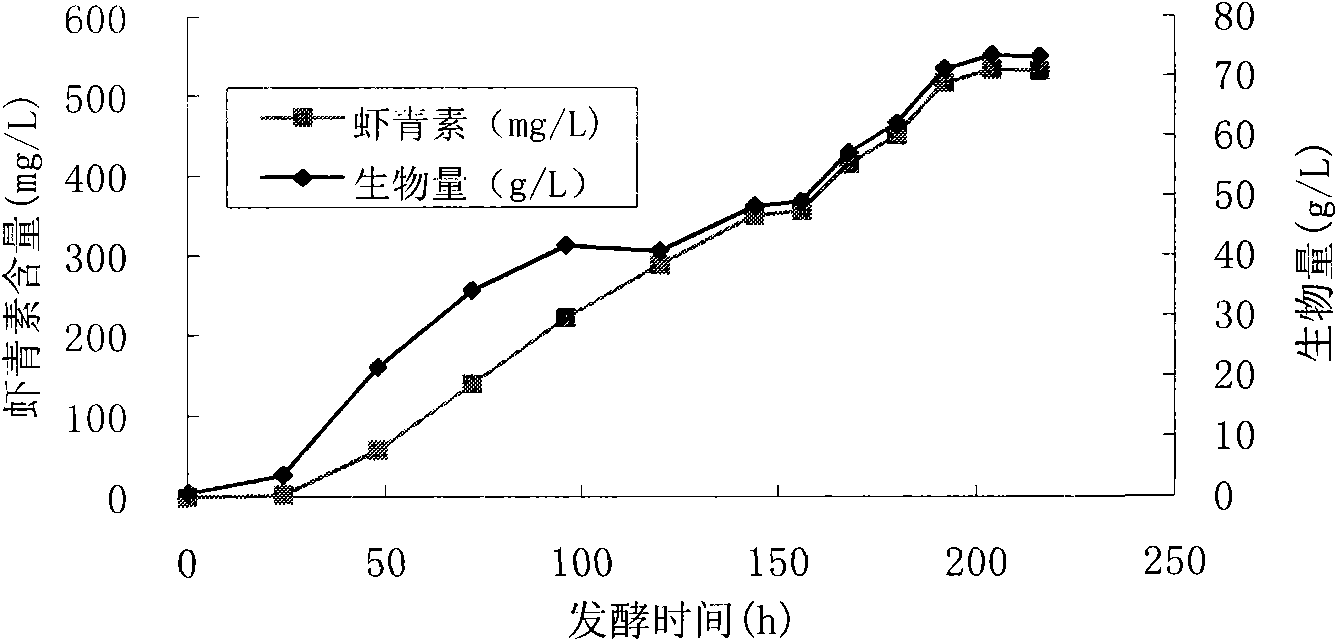

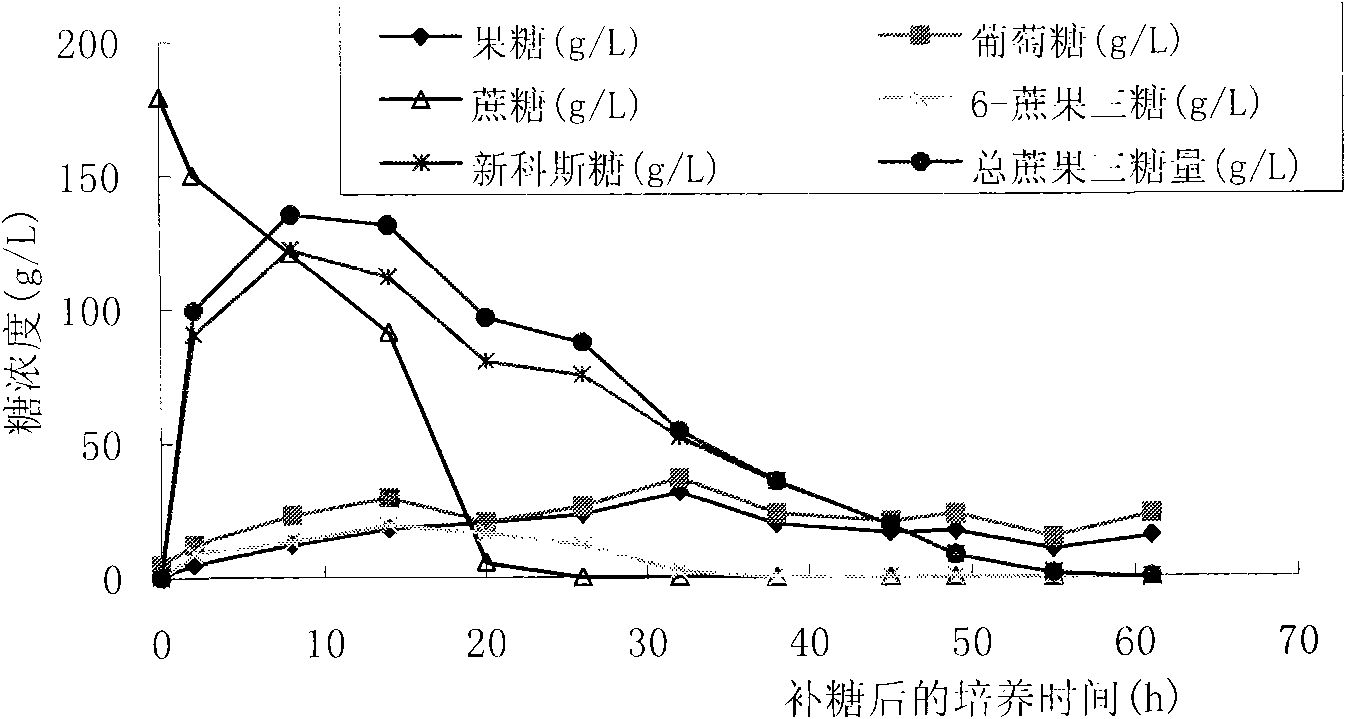

Fermentation method of co-production of astaxanthin and Fructooligosaccharide

ActiveCN101886108BRealize co-production fermentationIncrease productionMicroorganism based processesFermentationHigh concentrationGlucose-Fructose Syrup

The invention discloses a fermentation method which uses Phaffia rhodozyma to coproduce astaxanthin and Fructooligosaccharide, comprising the following main technical flows: culturing strains, carrying out high-yield fermentation on astaxanthin, replenishing high-concentration cane sugar and glucose syrup, and controlling the condition to covert and produce Fructooligosaccharide. The invention is mainly characterized in that when astaxanthin fermentation almost ends, the mixture of high-concentration cane sugar and glucose syrup is replenished, and the Fructooligosaccharide is obtained by conversion. The method utilizes Phaffia rhodozyma cultured in one batch to simultaneously produce astaxanthin and Fructooligosaccharide at high yield, thus greatly lowering the cost for culturing Phaffia rhodozyma and producing astaxanthin.

Owner:厦门联合伟业科技有限公司

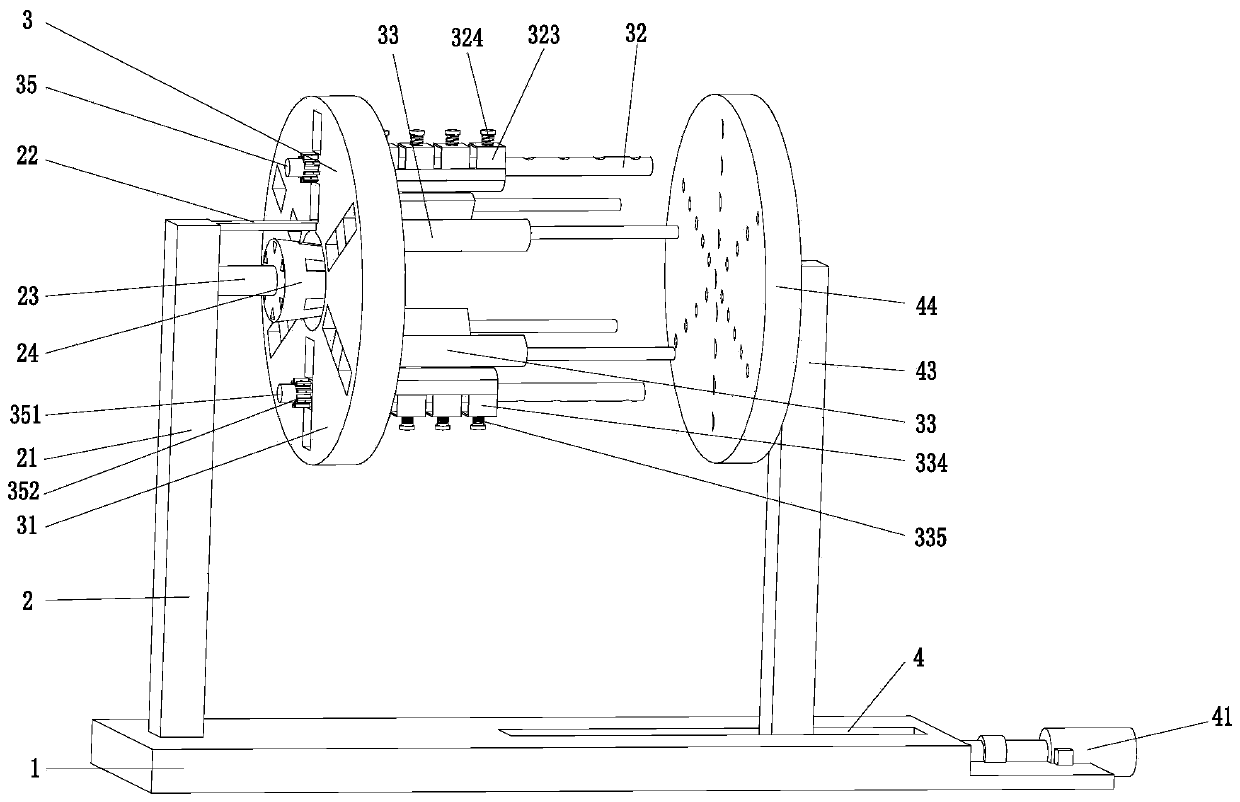

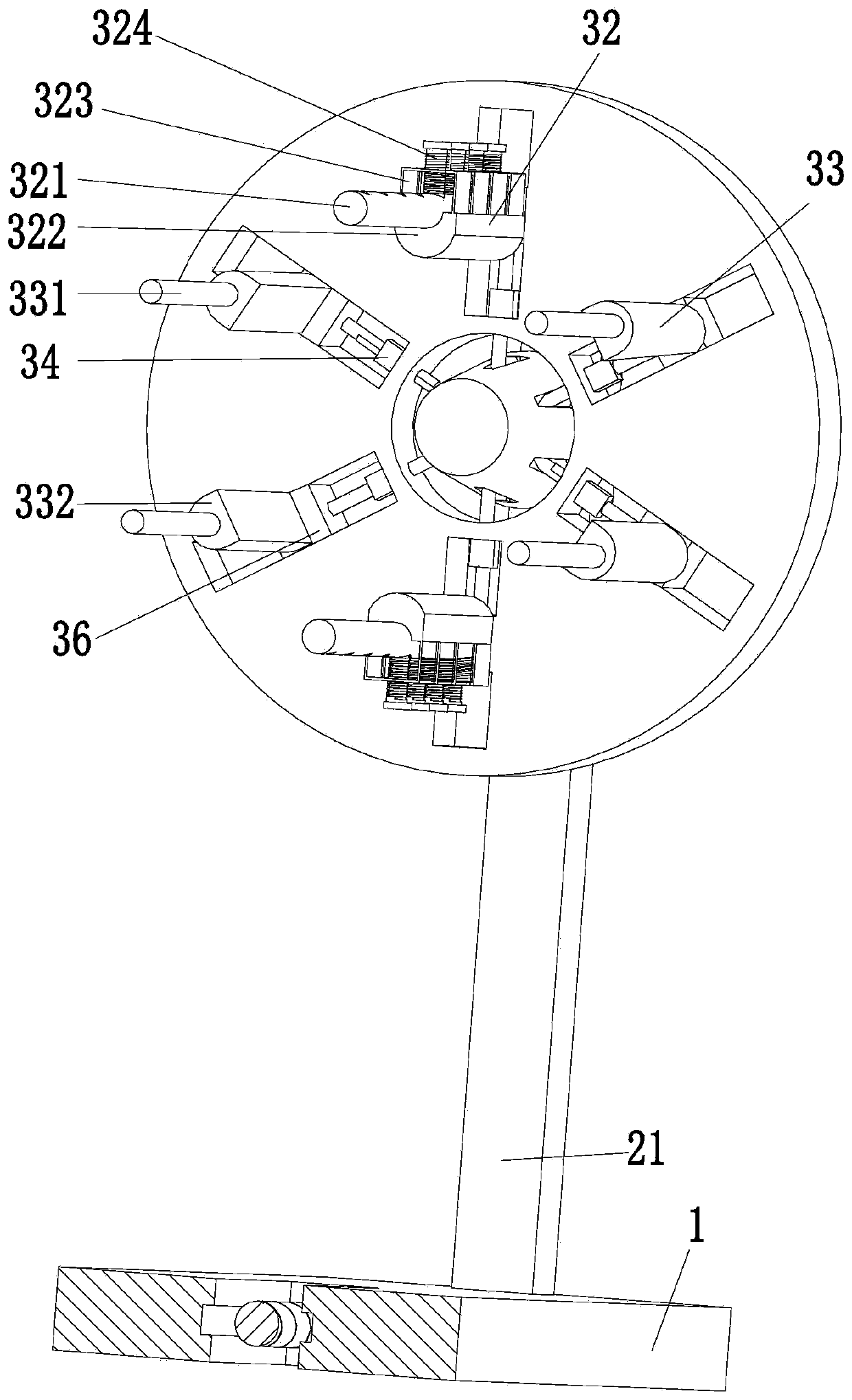

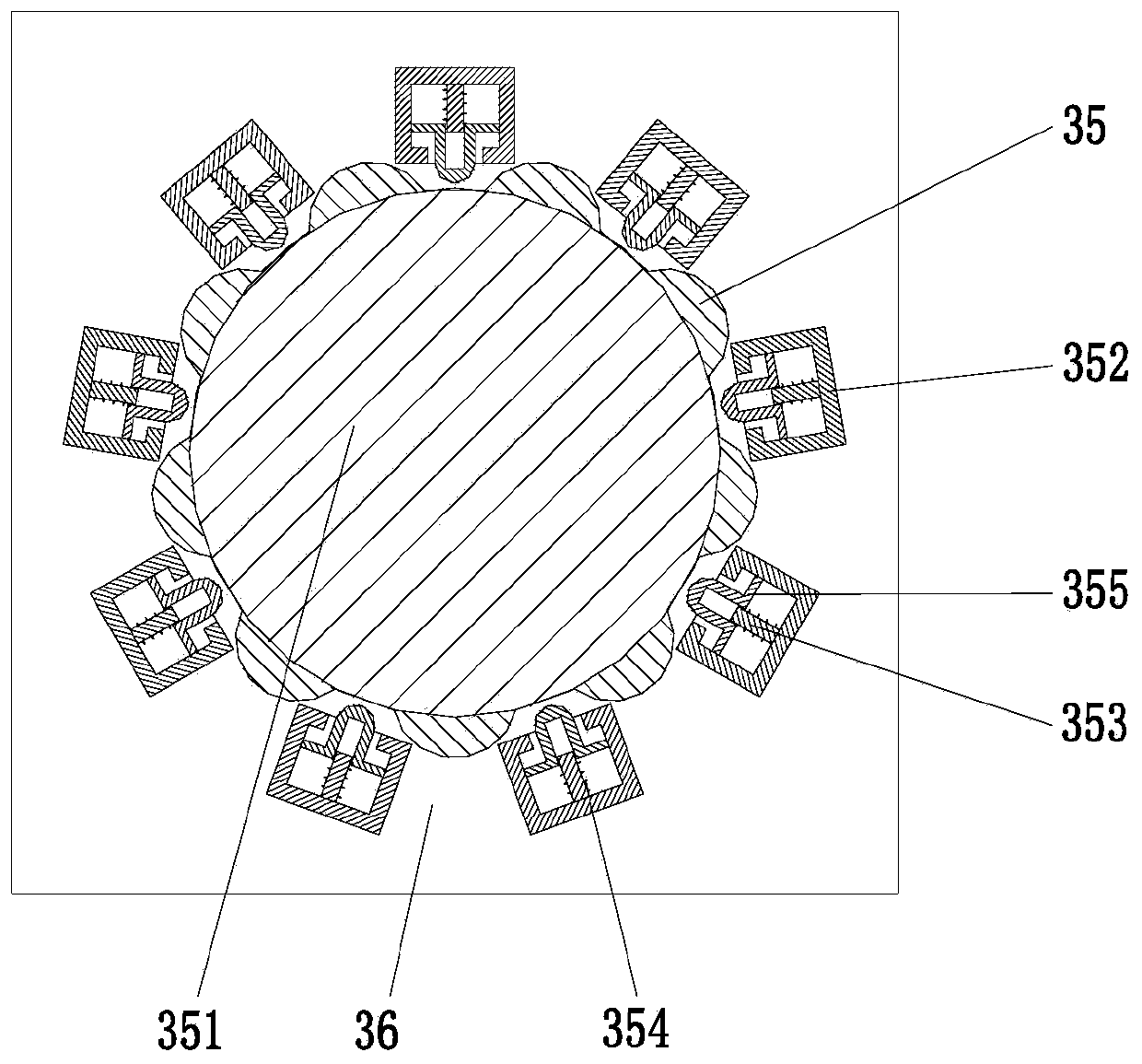

Rubber tire bead manufacturing and shaping processor

The invention relates to a rubber tire bead manufacturing and shaping processor. The rubber tire bead manufacturing and shaping processor comprises a bottom plate, a driving unit, an execution unit and an auxiliary unit, wherein the driving unit is arranged on the left side of the upper end face of the bottom plate, and the execution unit is installed at the upper end of the driving unit; and theauxiliary unit is installed on the right side of the upper end face of the bottom plate in a sliding fit mode. The processor can solve the following problems generated in the production process of tire beads at present: a, an existing produced tire bead has higher viscosity and is easy to deform, so that the rejection rate of the produced tire bead is higher; b, the tire beads produced by existingtire bead production equipment are single in specification and cannot be produced at the same time; and c, when the existing tire bead production equipment is used for producing different specifications of tire beads, the replacement operation time is too long, and the manufacturing cost is high.

Owner:周洋

Heat recovery type air cooling heat pump unit

ActiveCN102022858BRealize switchingImprove supply capacityEnergy recovery in ventilation and heatingHeat recovery systemsVapor–liquid separatorHeat conservation

The invention discloses a heat recovery type air cooling heat pump unit comprising a first refrigerant circulating system and a second refrigerant circulating system, wherein the first refrigerant circulating system comprises a first compressor, a first four-way valve, a second four-way valve, a first air side fin type heat exchanger, an air conditioner side heat exchanger, a first air-liquid separator, a total heat recovery heat exchanger, a hot water circulating water pump, a heat preservation water tank and a valve; the second refrigerant circulating system comprises a second compressor, athird four-way valve, a fourth four-way valve, a second air side fin type heat exchanger, an air conditioner side heat exchanger, a third reservoir, a second air-liquid separator, a partial heat recovery heat exchanger, a heat preservation water tank and a valve. According the invention, heat is ensured to be effectively recovered and reused, and environment is protected from thermal pollution, thereby being environmental friendly and saving energy. In addition, the defects that air conditioner heating and daily hot water supply can not be carried out simultaneously, and the traditional totalheat recovery air conditioner system which only has a single heat recovery system can not produce higher-temperature daily hot water at low temperature in winter can be effectively overcome.

Owner:GUANGDONG EUROKLIMAT AIR CONDITIONING & REFRIGERATION

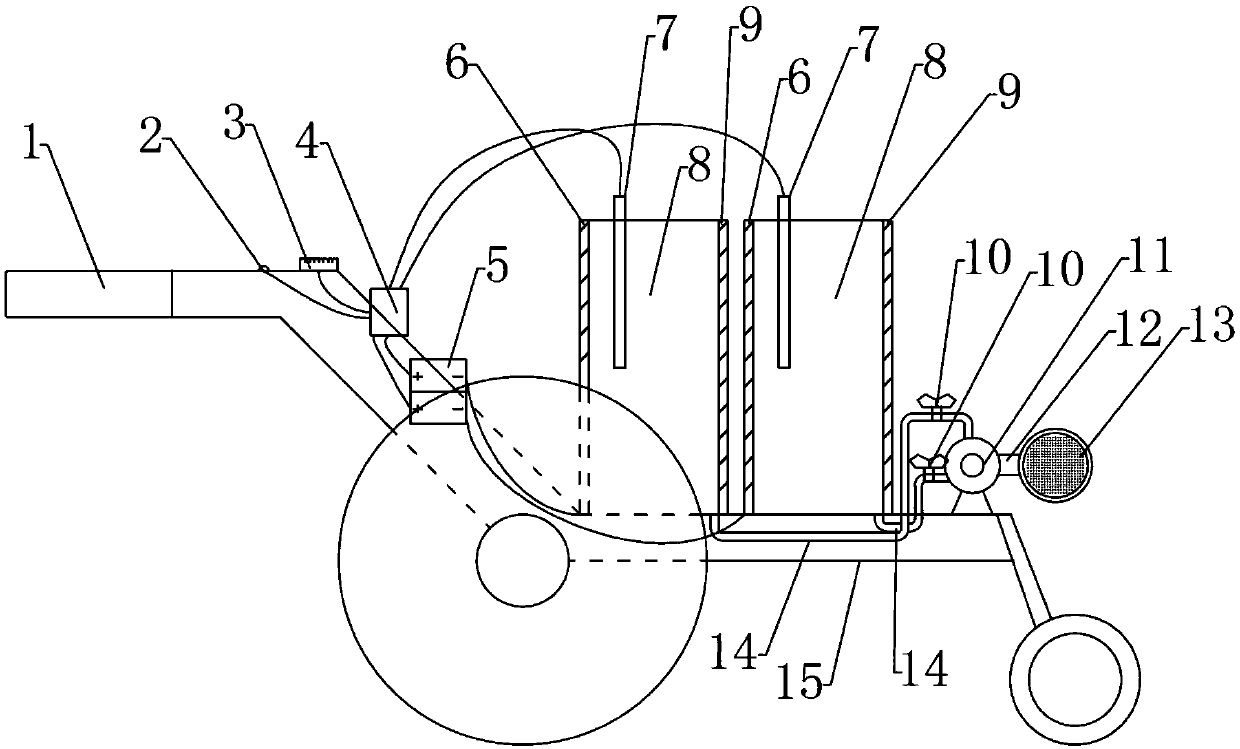

Trolley type electrolyte fertilizer production and spraying device

InactiveCN107593072AEasy to moveSuitable for large area plantingElectrolysis componentsClimate change adaptationElectrolysisControl system

The invention belongs to the technical field of fertilizer spraying and particularly relates to a trolley type electrolyte fertilizer production and spraying device. As for crops with lower planting density, such as forest planting, the demand of electrolyte fertilizer in the unit area is not high, but the planting area is larger; at the moment, great inconvenience is caused due to the fact that arunning water electrolytic tank device is fixed in one position for production of electrolyte fertilizer, and the fertilizer application efficiency is affected. According to the technical scheme, thedevice comprises a pushing handle and a trolley body, wherein an electrolyte fertilizer production device, a liquid extraction pump and a spray head are mounted on the trolley body; the electrolyte fertilizer production device comprises an electrolysis cavity, a negative plate and a positive plate are arranged in the electrolysis cavity, a liquid discharging pipe is arranged at the lower part ofthe electrolysis cavity and connected with the liquid extraction pump. The electrolyte fertilizer production device can also integrate a control system. The trolley type electrolyte fertilizer production and spraying device is applicable to spraying of the electrolyte fertilizer to crops with low planting density.

Owner:SICHUAN GUANTENG TECH CO LTD

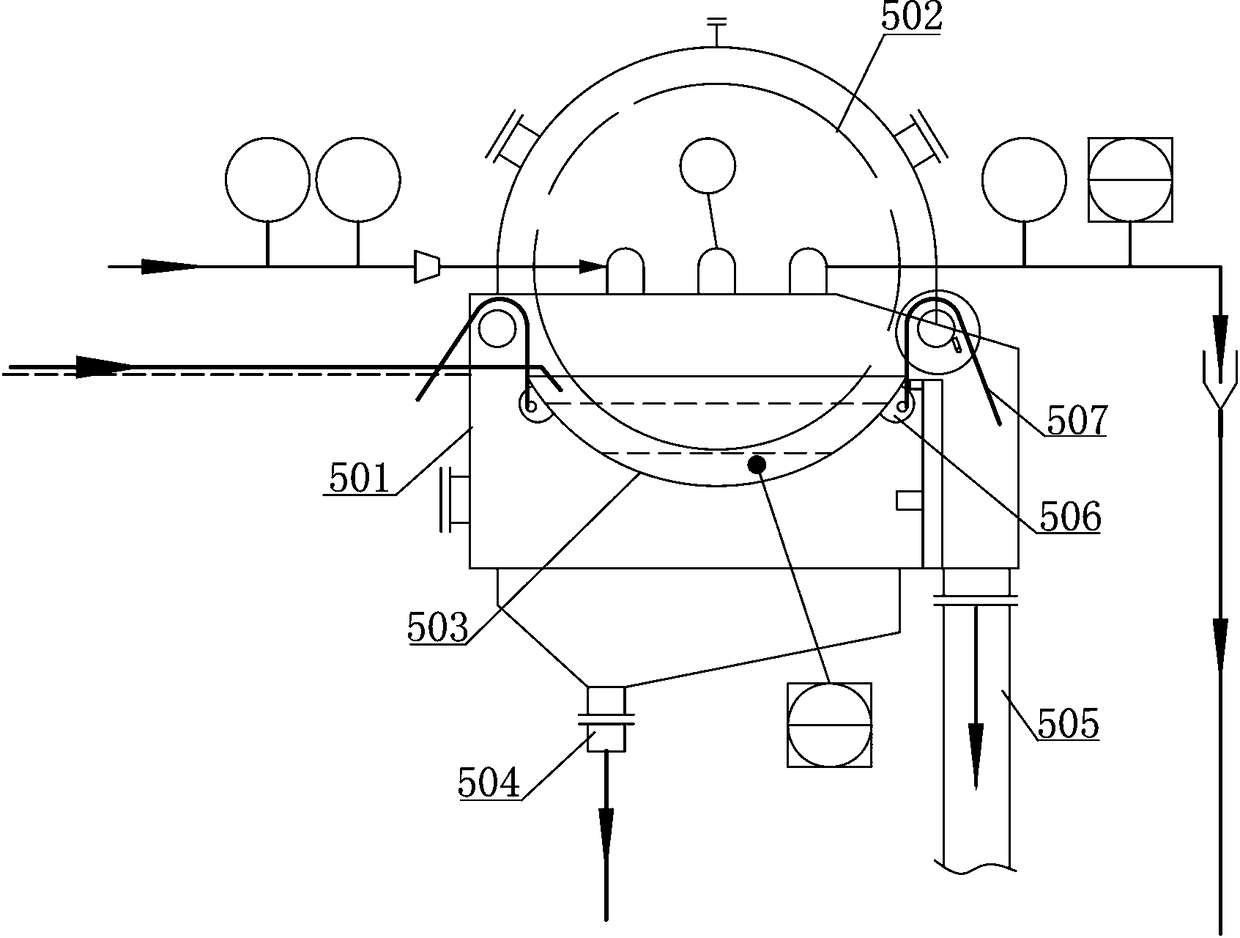

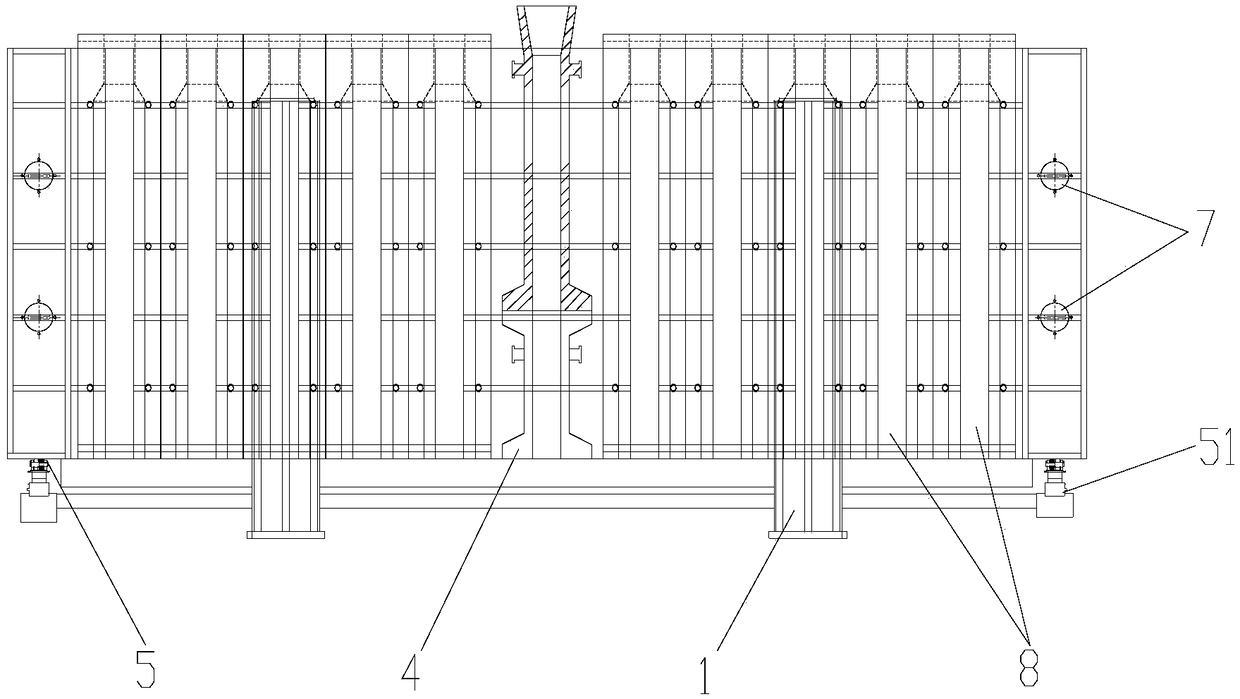

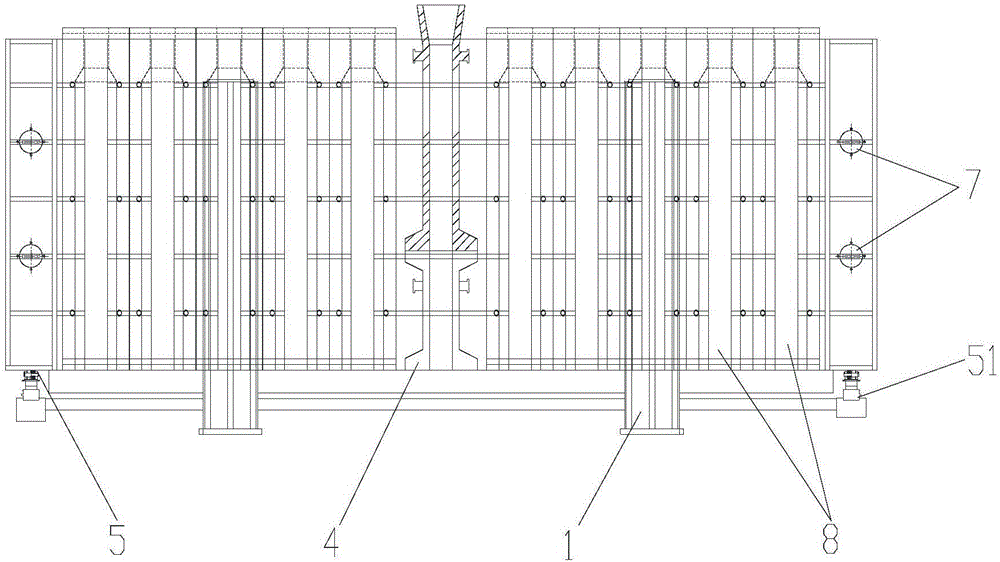

Molten steel casting device

The invention provides a molten steel casting device. The molten steel casting device comprises two or more U-shaped frames, a mold body and a casting chassis. The two or more U-shaped frames are installed at intervals side by side, and a right stand column and a left stand column of each U-shaped frame are each provided with a set of driving hydraulic cylinders correspondingly. The mold body comprises a left mold bed and a right mold bed, the left mold bed is connected with the driving hydraulic cylinders installed on the left stand columns of all the U-shaped frames, and the right mold bed is connected with the driving hydraulic cylinders installed on the right stand columns of all the U-shaped frames; and the casting chassis is arranged on the two or more U-shaped frames horizontally, a casting passage is formed in the casting chassis, under the state that the left mold bed is attached with the right mold bed, the left mold bed and the right mold bed are locked by disc spring locking cylinders, the left mold bed, the right mold bed and the casting chassis are enclosed to form a plurality of pouring cavities, and the multiple pouring cavities all communicate with the casting passage. According to the molten steel casting device, casting of molten steel is achieved quickly and automatically, producing efficiency is improved, labor intensity is reduced, and the accident rate is reduced.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Molten steel casting device

The invention provides a molten steel casting device. The molten steel casting device comprises two or more U-shaped frames, a mold body and a casting chassis. The two or more U-shaped frames are installed at intervals side by side, and a right stand column and a left stand column of each U-shaped frame are each provided with a set of driving hydraulic cylinders correspondingly. The mold body comprises a left mold bed and a right mold bed, the left mold bed is connected with the driving hydraulic cylinders installed on the left stand columns of all the U-shaped frames, and the right mold bed is connected with the driving hydraulic cylinders installed on the right stand columns of all the U-shaped frames; and the casting chassis is arranged on the two or more U-shaped frames horizontally, a casting passage is formed in the casting chassis, under the state that the left mold bed is attached with the right mold bed, the left mold bed and the right mold bed are locked by disc spring locking cylinders, the left mold bed, the right mold bed and the casting chassis are enclosed to form a plurality of pouring cavities, and the multiple pouring cavities all communicate with the casting passage. According to the molten steel casting device, casting of molten steel is achieved quickly and automatically, producing efficiency is improved, labor intensity is reduced, and the accident rate is reduced.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Continuous shearing and pressing device for rigid thin band

InactiveCN100384575CSimultaneous productionImprove continuityMetal-working feeding devicesLaminationEngineeringMechanical engineering

The invention relates to a stiff thin tape continuous shearing and press-plaster device in mechatronics domain, which comprises tape-guiding parts, tape-pinching parts, tape shearing and press-plaster parts and shifting parts. Tape-guiding parts comprise guide runner, material-leading grid and striker grid; tape-pinching parts comprise pinch-off blades, clamping cylinder, actuating motor running gear and slider of pinching parts; tape-pinching parts comprise shearing cylinder, scissors and so on; shifting parts comprise driving motor, running gear and slider. The invention improves productive efficiency and can be used in automated producing equipment of metal anti-theft label.

Owner:SHANGHAI JIAOTONG UNIV

Amoled pixel circuit, driving method thereof, and display device

ActiveCN103310734BHighly integratedQuality improvementStatic indicating devicesInput/output processes for data processingComputer hardwareDisplay device

An AMOLED pixel circuit, a drive method of same, and a display device. The pixel circuit and the drive method of same can enhance the integration between a built-in touch circuit and an AMOLED drive circuit. The AMOLED pixel circuit comprises a light-emitting module (11), a touch module (12), a control module (13), and a drive amplification module (14). The AMOLED pixel circuit is used to manufacture an AMOLED display device.

Owner:BOE TECH GRP CO LTD +1

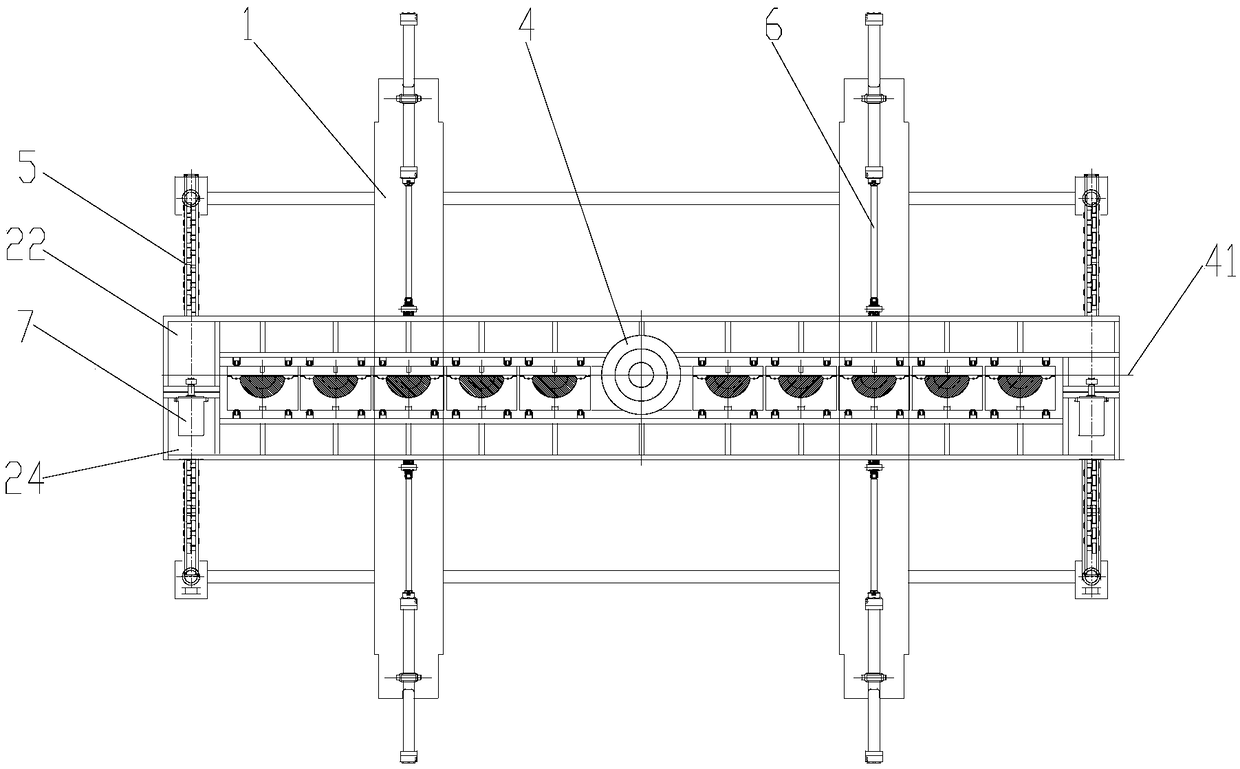

Spinning device with double-drive draft control and spinning method thereof

ActiveCN109837616BEnabling fully independent draft controlSimultaneous productionContinuous wound-up machinesYarnSpinning

The invention discloses a spinning device with double-drive draft control and a spinning method thereof. Two adjacent spindle positions form a spindle position group, and the left spindle position roller sleeve of the spindle position group is fixedly connected with the roller shaft, and the right spindle position The roller sleeves of the side spindle position are connected with the roller shaft bearings, and the front, middle and rear transmission shafts are arranged at the front of the roller shafts of the front, middle and rear bottom rollers. The roller sleeves of the right spindle position are driven by the transmission shafts through the belt. The right end of the roller shaft is driven by the first motor, and the right end of the front, middle and rear roller shafts is connected by the first set of gears, so that the first transmission system is formed for the left spindle position of all the spindle position groups, and the right end of the front drive pull shaft is driven by the second gear set. Driven by the motor, and the right end of each transmission shaft is connected by the second set of gears, so that the second transmission system is formed for the right spindles of all the spindle groups, and the two spindles in the spindle group can completely independently pull the roving. stretch control, and then realize the simultaneous production of two types of yarn on one spinning frame.

Owner:JIANGNAN UNIV

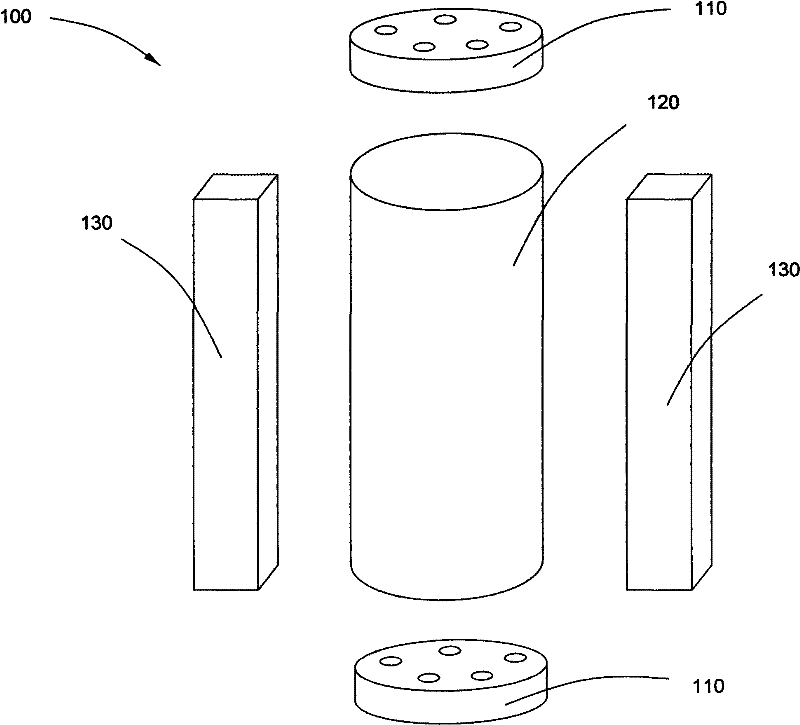

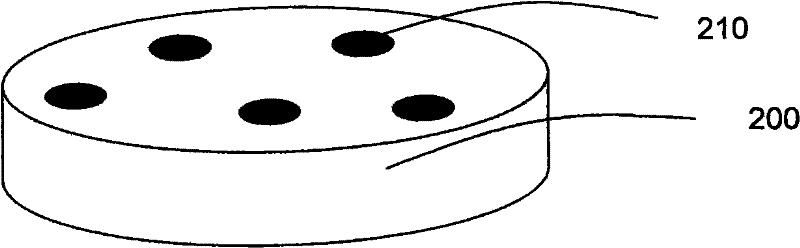

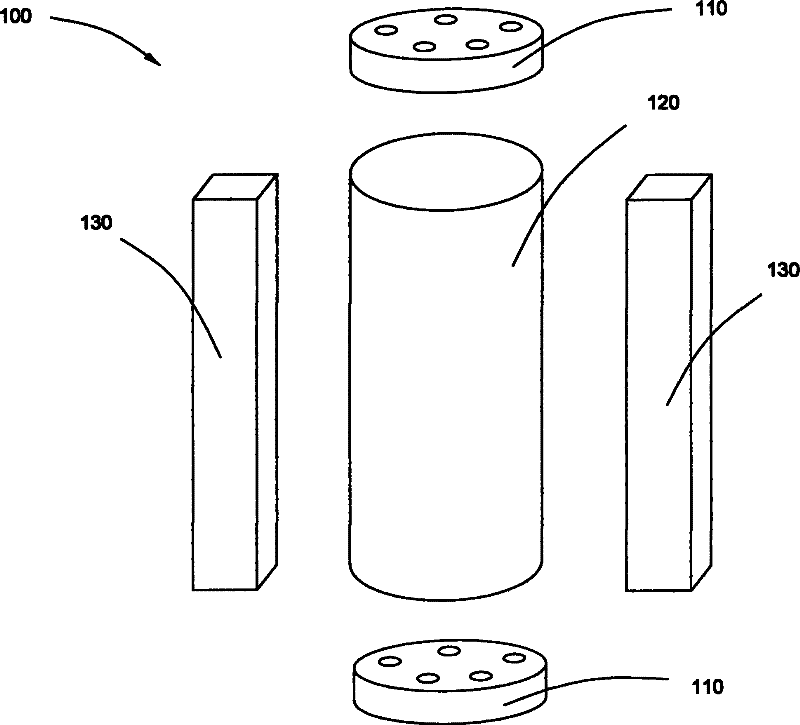

Manufacturing method of embedded metal through-hole wafer and device thereof

ActiveCN101746710ALow costShorten the production cycleDecorative surface effectsChemical vapor deposition coatingRoom temperatureEngineering

The invention relates to a manufacturing method of an embedded metal through-hole wafer and a device thereof, wherein the method comprising the following steps: linear metal penetrates through the through holes of a bearing device and the bottom part of a die, passes through the accommodating cavity of the die, penetrates through the through hole of another bearing device, and then is fixed at both ends of each bearing device to be strained. The raw material of the wafer is poured into the accommodating cavity of the die, the die is heated to the temperature of more than 100 DEG C of the softening point of the raw material of the wafer, and then the heat is preserved for at least 10 minutes. The die is cooled to the room temperature, and a wafer cylinder is taken out and is cut to obtain the wafer with the metal through hole. The manufacturing method of an embedded metal through hole wafer and the device thereof have low wafer manufacturing cost, help the a large number of wafer production, and can let the wafer widely used.

Owner:MEMSIC SEMICON WUXI

Method for producing flaxseed gum and flaxseed kernels

ActiveCN102513177BLoose combinationAchieve strippingGrain huskingGrain polishingOrganic solventEngineering

The invention relates to a method for producing flaxseed gum and flaxseed kernels, which is characterized by comprising the following steps of: 1, cleaning and removing impurities; 2, polishing and degumming and separating the gum from the flaxseed kernels: putting clean flaxseeds into a sand roller polishing machine for polishing the flaxseed gum on the surface layer of the flaxseeds into gum powder, sucking the gum powder through a screen net of the sand roller polishing machine by an air suction duct, collecting to obtain the flaxseed gum powder, collecting flaxseed grains of the sand roller polishing machine; 3, grinding, twisting and shelling the flaxseed grains; 4, separating shells from kernels to obtain the flaxseed kernels: conveying a shelled flaxseed shell / kernel mixture to a shell / kernel separating machine to respectively obtain flaxseed shells, flaxseed kernels and unshelled flaxseed grains; and 5, degreasing the gum powder to obtain the flaxseed gum: screening the flaxseed gum powder, degreasing the screened gum powder by adopting an organic solvent, and drying to obtain the flaxseed gum. According to the method, the flaxseed gum and complete flaxseed kernels and flaxseed shells can be simultaneously obtained.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

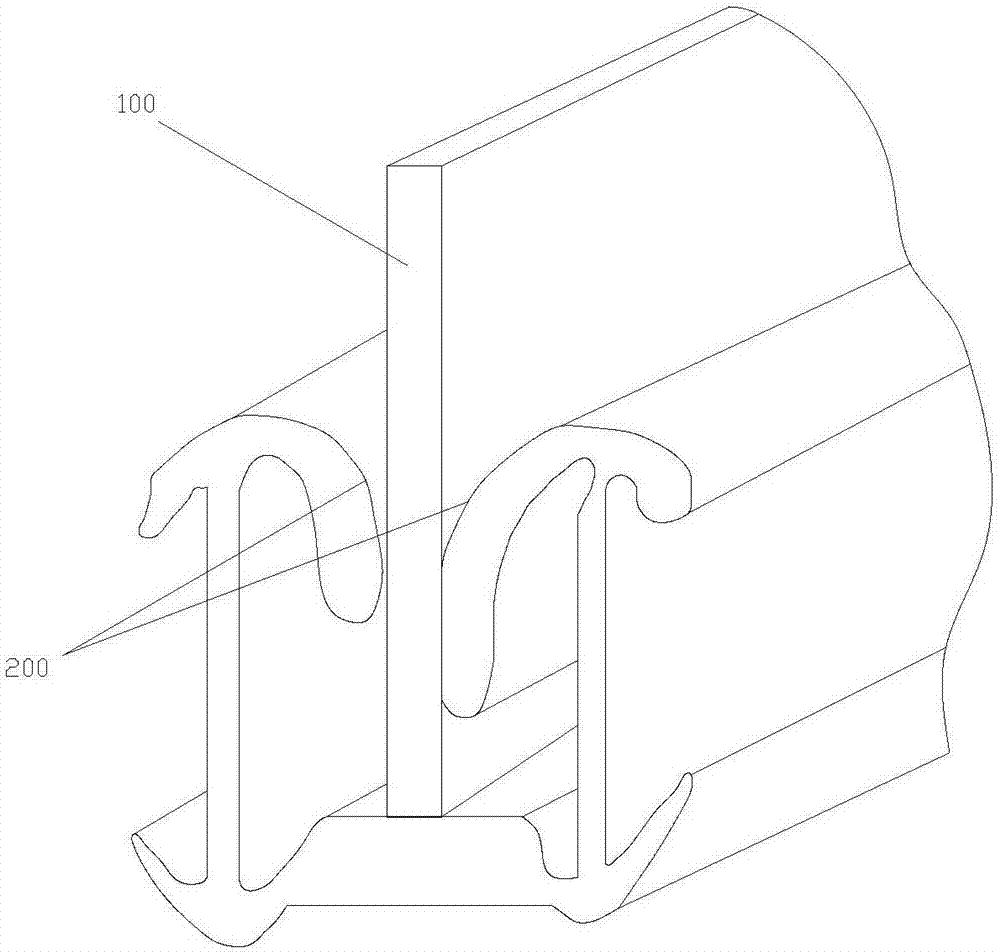

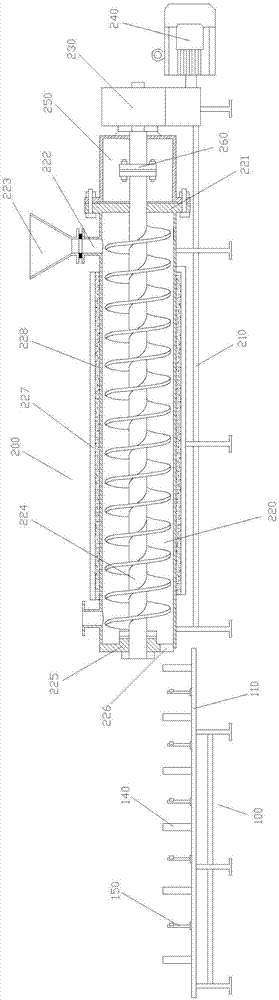

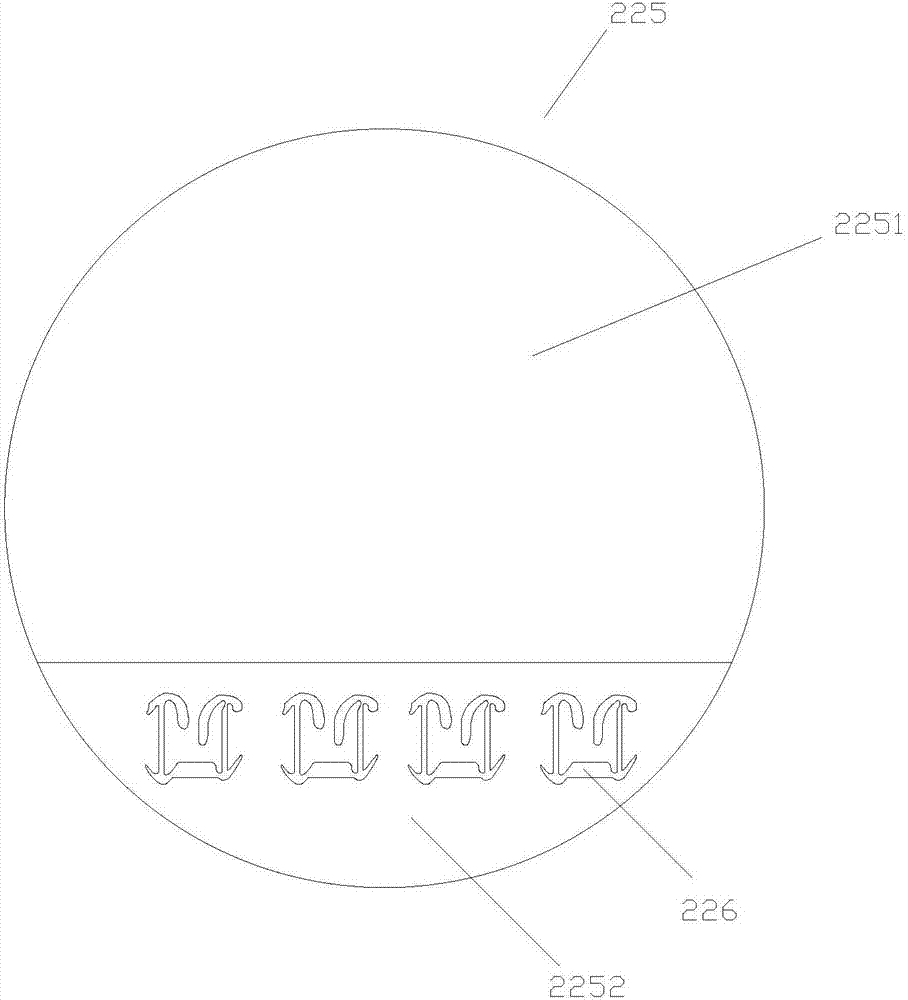

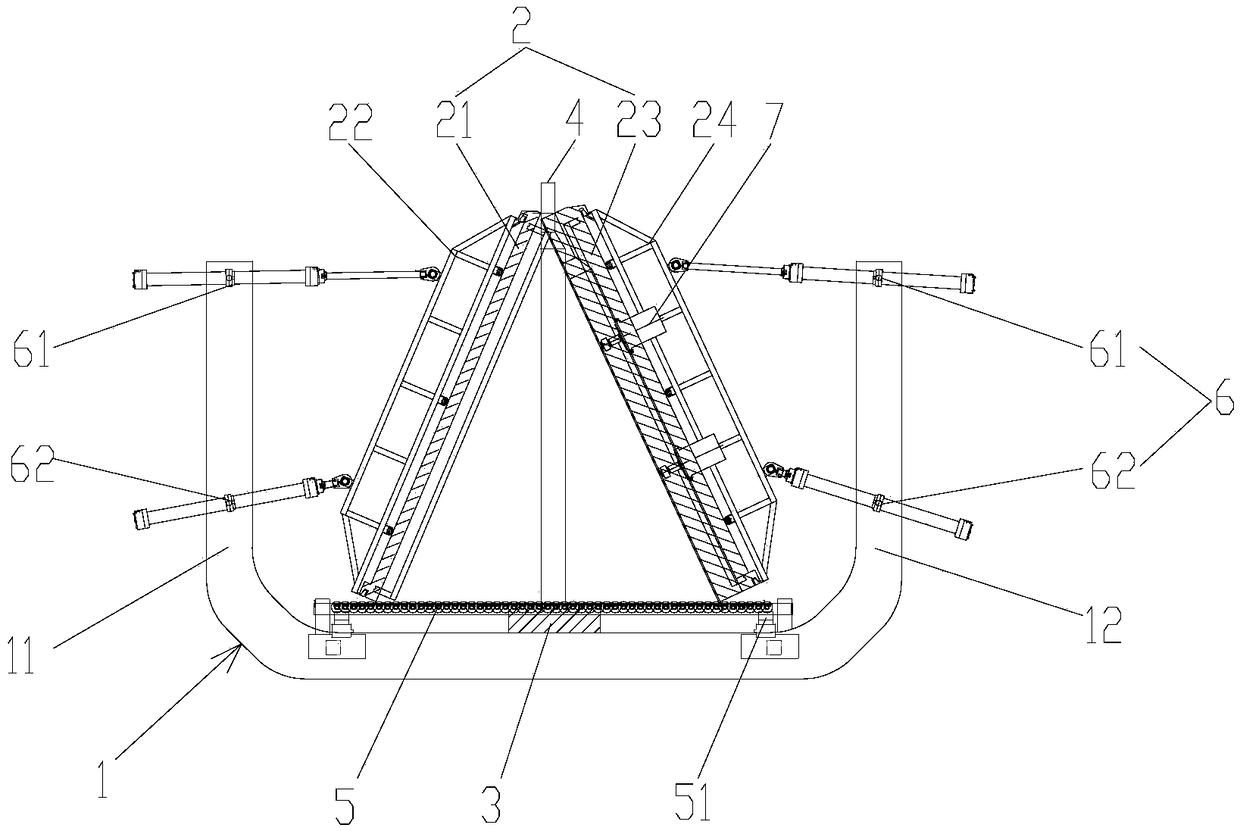

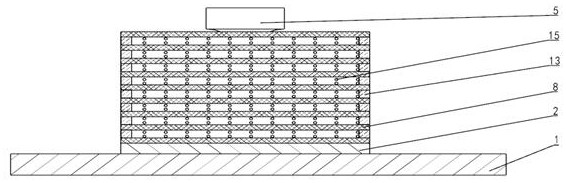

A nanofiltration membrane preparation device and production process

ActiveCN109731475BQuick thickness adjustmentQuick stackReverse osmosisLiquid spraying apparatusEngineeringPipe

Owner:JIANGSU QIXING FLUID EQUIP CO LTD

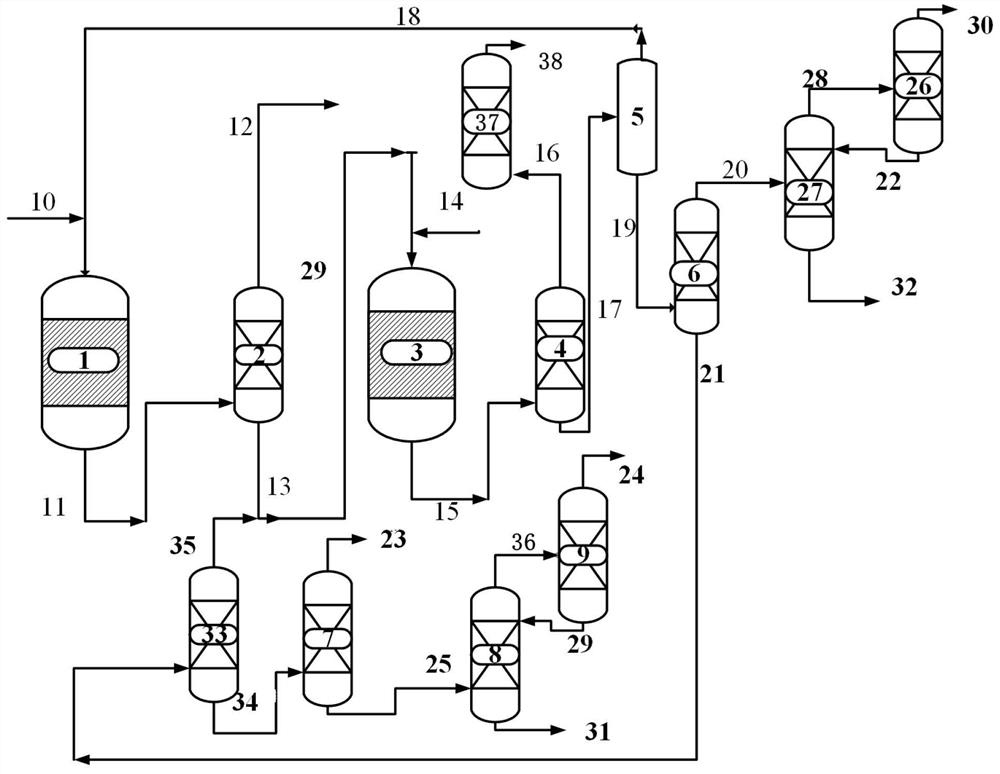

HFO-1234ze and HCFO-1233zd co-production process and co-production system

ActiveCN113527039ASimultaneous productionIncrease productivityPreparation by hydrogen halide split-offPreparation by halogen replacementProcess engineeringIndustrial engineering

The invention relates to a HFO-1234ze and HCFO-1233zd co-production process and co-production system. By taking HCC-240fa and anhydrous HF as raw materials, four products, namely E-HFO-1234ze, Z-HFO-1234ze, E-HCFO-1233zd and Z-HCFO-1233zd, are co-produced. The process realizes simultaneous production of various high-added-value products, and is simple in process flow, high in production efficiency and low in investment cost.

Owner:陕西中蓝化工科技新材料有限公司 +2

Amoled pixel circuit, driving method thereof, and display device

ActiveCN103345901BHighly integratedQuality improvementStatic indicating devicesInput/output processes for data processingDriver circuitDisplay device

The invention discloses an AMOLED pixel circuit, a driving method thereof, and a display device, which relate to the field of display technology and can improve the integration degree of an embedded touch control circuit and an AMOLED driving circuit. The AMOLED pixel circuit includes: a light-emitting module, a touch module, a control module and a driving and amplifying module. The embodiment of the present invention is used to manufacture an AMOLED display device.

Owner:BOE TECH GRP CO LTD +1

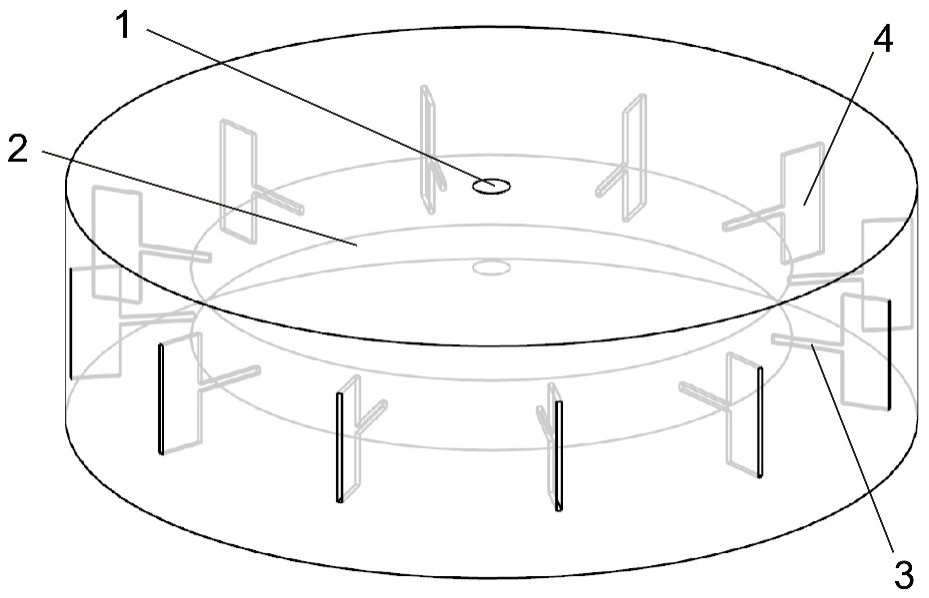

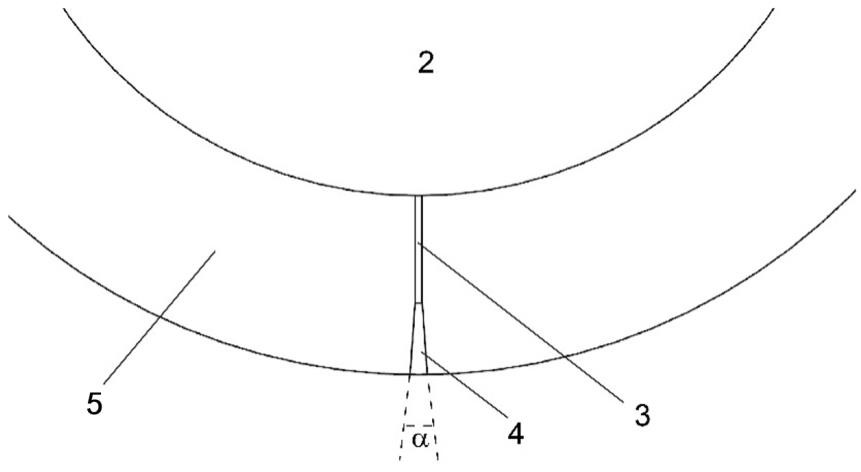

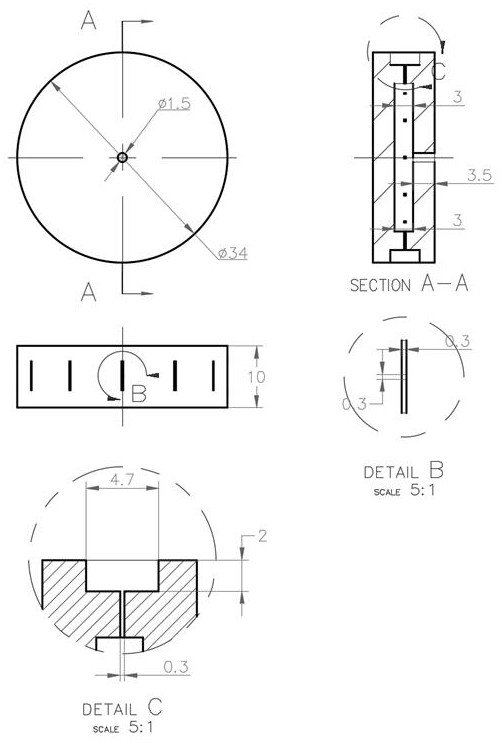

A 3D printed microfluidic device and its large-throughput method for preparing monodisperse emulsions

ActiveCN110075934BHigh volume fraction of dispersed phaseGood monodispersityLaboratory glasswaresEmulsionMicrofluidics

The invention provides a 3D printing microfluidic device and a method for preparing a monodisperse emulsion with large throughput. 3D printing is used to make microfluidic devices. The device is in the shape of a cylinder with a cylindrical channel in the center. The liquid buffer channel is connected to multiple radially distributed microchannels. The microchannels are connected to the external collection tank through the slit area. The slit The area is flat and wedge-shaped. When the dispersed phase is injected from the liquid inlet, enters the liquid buffer channel, flows into the radially distributed microchannels from the liquid buffer channel, and when the fluid enters the flat slit area through the microchannel, under the extrusion of the side of the slit, it has a relatively Large Laplace pressure, the wedge-shaped structure will cause the droplet to be subjected to a Laplace pressure difference between the inside and outside, the pressure difference pushes the droplet to flow in the wedge-shaped structure, and finally squeezes the droplet from the wedge-shaped structure to the collection tank middle. The size of the generated droplets can be controlled by changing the structural parameters of the channel, and the size of the prepared droplets is uniform, so that a large number of monodisperse emulsions with uniform and controllable sizes can be prepared. The method has the advantages of simple manufacture and low cost, and can realize industrialized production.

Owner:绍兴钠钇光电有限公司

Integrated transmission spinning device with controllable single-spindle yarn number and spinning method

The invention discloses an integrated transmission spinning device with controllable single-spindle yarn number and a spinning method. A drafting system adopts three rollers, the rollers are integrally and fixedly connected with roller shafts, one spindle position and an adjacent spindle position form a spindle position group, the roller shaft of the spindle position on the right side is fixedly connected with the roller sleeve, the roller shaft on the spindle position on the left side is connected with the roller sleeve through a bearing, the spindle roller on the right side is connected through a variable speed gear, rubber rollers on each spindle position are independently arranged, rubber roller shafts on left and right sides are connected through a bearing, a roller shaft of a lower front roller is driven by a motor and is in gear transmission connection with a middle lower roller and a rear lower roller, same coarse yarns are fed into the drafting system by each spindle positionsand drafted by the same rear and front drafting areas in the spindle position on the right side and drafted by the rear and front drafting areas determine by the variable speed gear in the spindle position on the left side, so that different drafting controls are achieved, and therefore the simultaneous production of yarns of multiple species by one spinning frame is achieved.

Owner:HEFEI ANLUYI TECH CO LTD

Mulberry leaf corn cordyceps militaris cake and preparation method thereof

PendingCN112219880ASimultaneous productionLow costModified nutritive productsBiotechnologyMeal replacement

The invention discloses a mulberry leaf corn cordyceps militaris cake and a preparation method thereof, the cake contains mulberry leaves, corn cordyceps militaris extraction residues, and the preparation method comprises the following steps: collecting culture medium residues produced in a cordyceps militaris mycelium culture process and cordyceps militaris extraction residues in mycelium nutrient solution; The mulberry leaf corn cordyceps militaris cake contains nutritional ingredients of mulberry leaves, corn and mycelia, most soluble saccharides in the corn are removed in the cooking and water extraction process, the requirement of people for low-sugar nutritional food can be met, and the cake can be used for daily health care and weight loss meal replacement.

Owner:TAIZHOU KANGJING BIOLOGICAL SCI & TECH +1

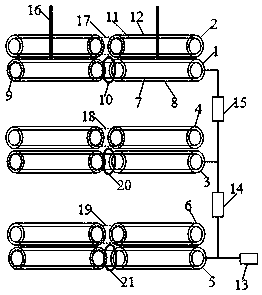

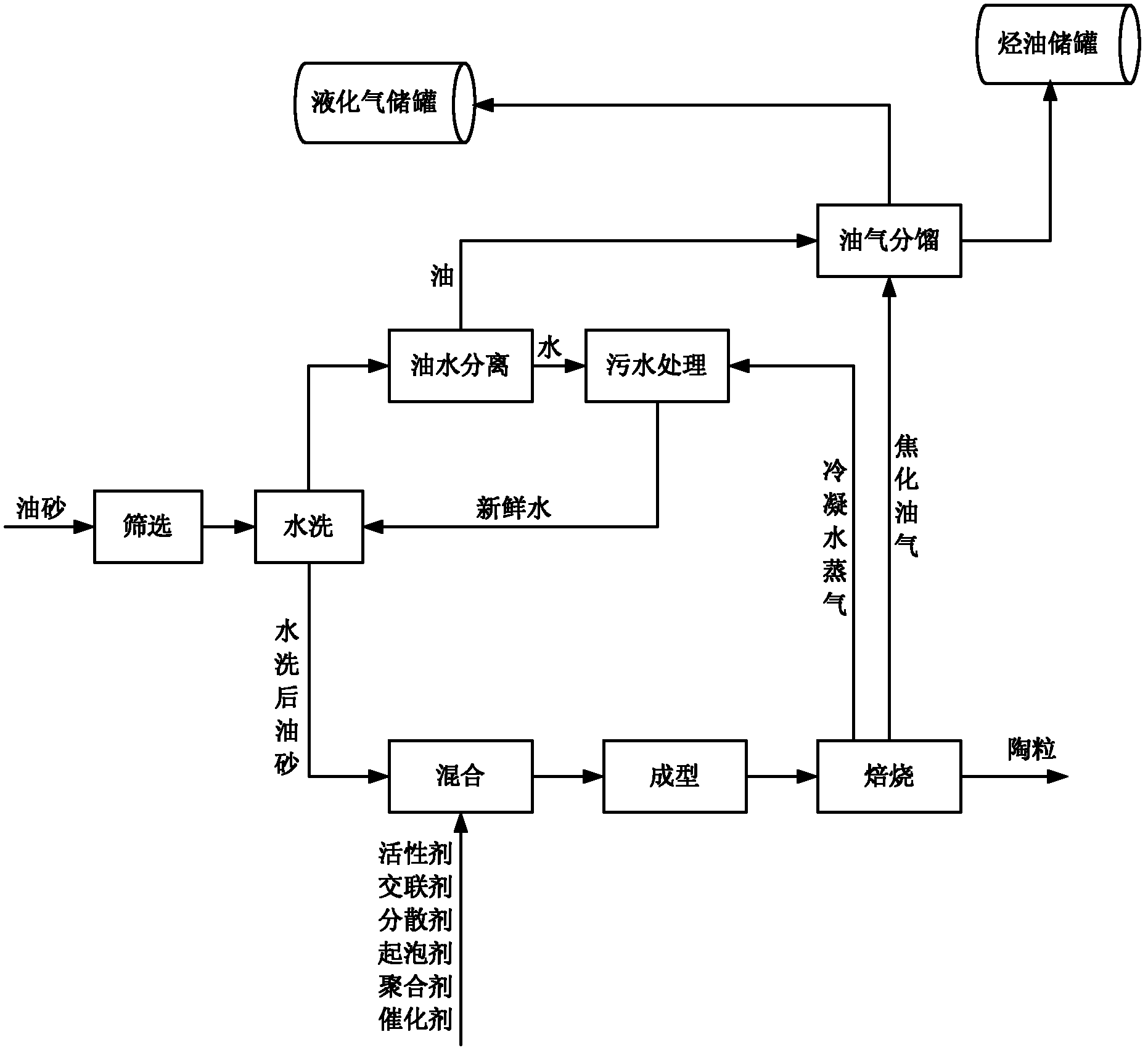

Method for extracting hydrocarbon oil from oil sand and producing ceramsite

InactiveCN102268277BSimultaneous productionIncrease the molding and granulation linkLiquid hydrocarbon mixture productionSpecial form destructive distillationMoving bed biofilm reactorFoaming agent

The invention provides a method for extracting hydrocarbon oil from oil sand and producing ceramic aggregates. The method mainly comprises the following steps of: mixing the oil sand with water, an activating agent, a crosslinking agent, a dispersing agent, a foaming agent, a polymerizer and a catalyst and forming into grains with grain diameter of 0.5-2cm; and heating the formed grains, performing dry distillation to obtain the hydrocarbon oil, sintering at the high temperature of 750-1,100 DEG C for 1-4 hours and cooling to obtain the ceramic aggregates. In the method, the density of the ceramic aggregates can be controlled to be 0.3-1.8g / cm<3> according to different proportions of additives. The ceramic aggregates can be used as a filler for a moving bed biofilm reactor to perform oil-containing sewage treatment and can also be used as a building material or a chemical product.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com