Integrated transmission spinning device with controllable single-spindle yarn number and spinning method

A single-spindle, production device technology used in spinning machines, textiles and papermaking, drafting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

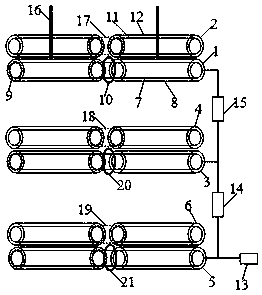

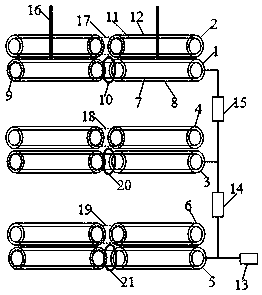

[0009] Depend on figure 1As shown, a centralized transmission single-spindle yarn count controllable spinning device includes a drafting system. The drafting system includes a pair of rear draft rollers, a pair of middle draft rollers, a pair of front draft rollers, and a pair of rear rollers. Roller 1 and rear top rubber roller 2, middle roller pair includes middle bottom roller 3 and middle upper rubber roller 4, front roller pair includes front bottom roller 5 and front top top roller 6, rear bottom roller, middle bottom roller, front bottom roller The structure is the same, the rear bottom roller, the middle bottom roller, and the front bottom roller include the roller shaft 7, the roller shaft is a solid cylindrical structure, and the roller shafts of the rear bottom roller of all the spindle positions on the front car table of a spinning frame are integrated Fixed connection, integrated fixed connection of roller shafts of middle and bottom rollers of all spindle positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com